Integrated variable speed driver of electric automobile

A variable speed drive, electric vehicle technology, applied in the field of key automotive parts, to achieve the effect of increasing the crushing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] as attached figure 1 to attach Figure 6 Shown:

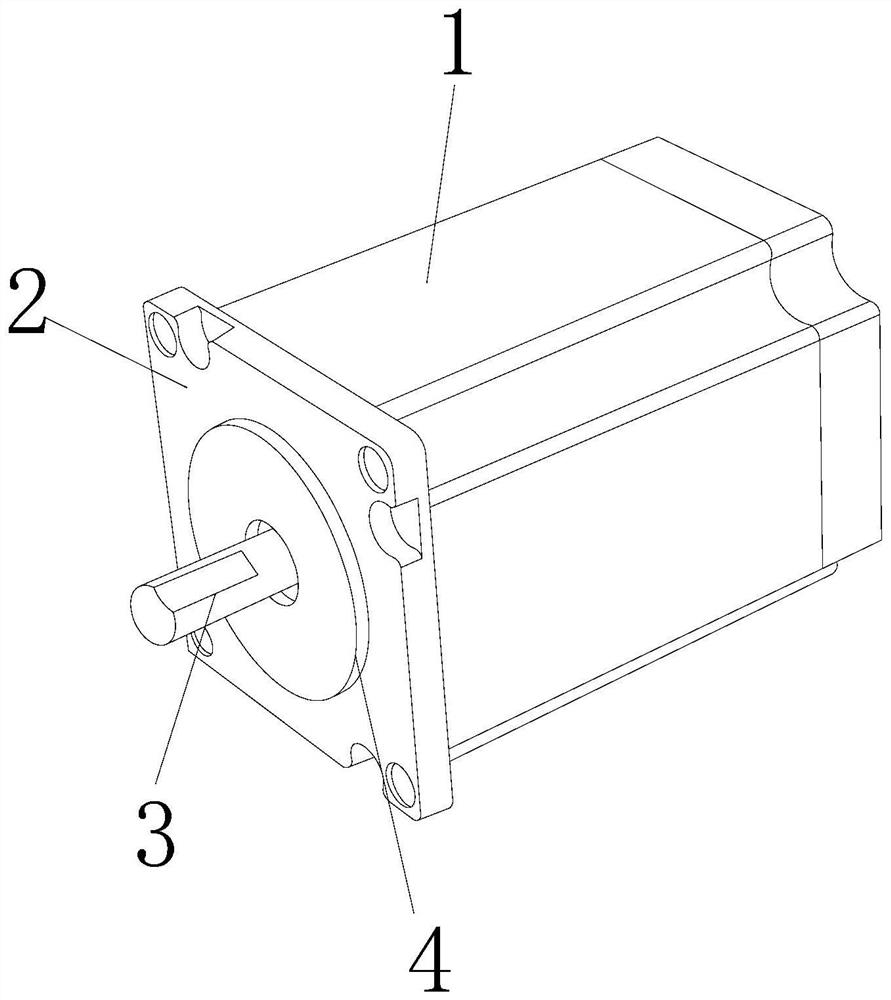

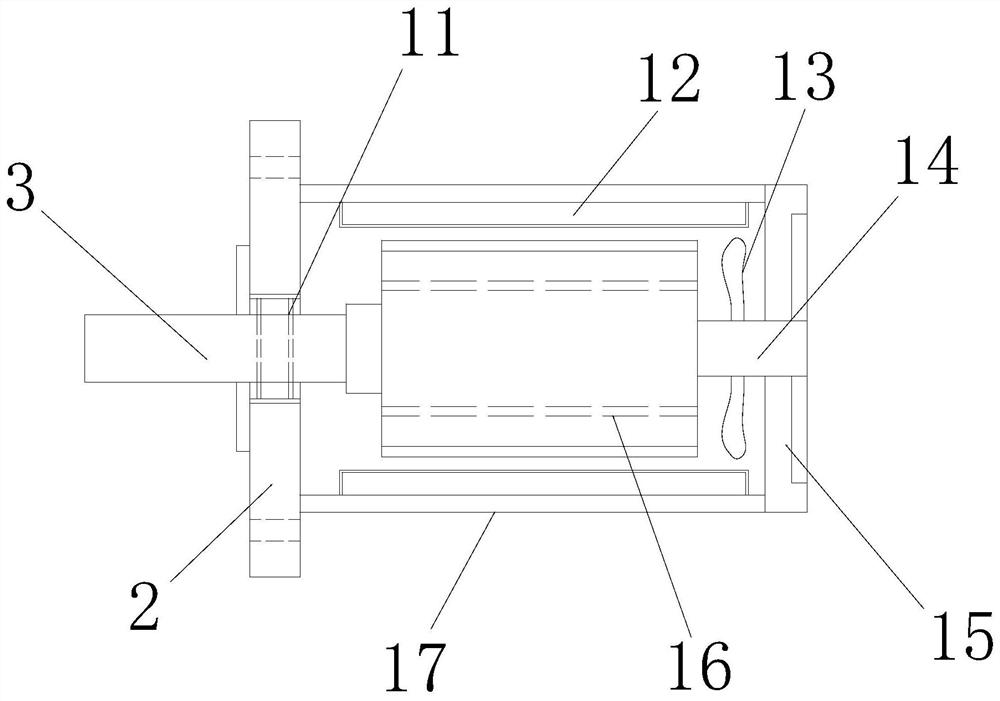

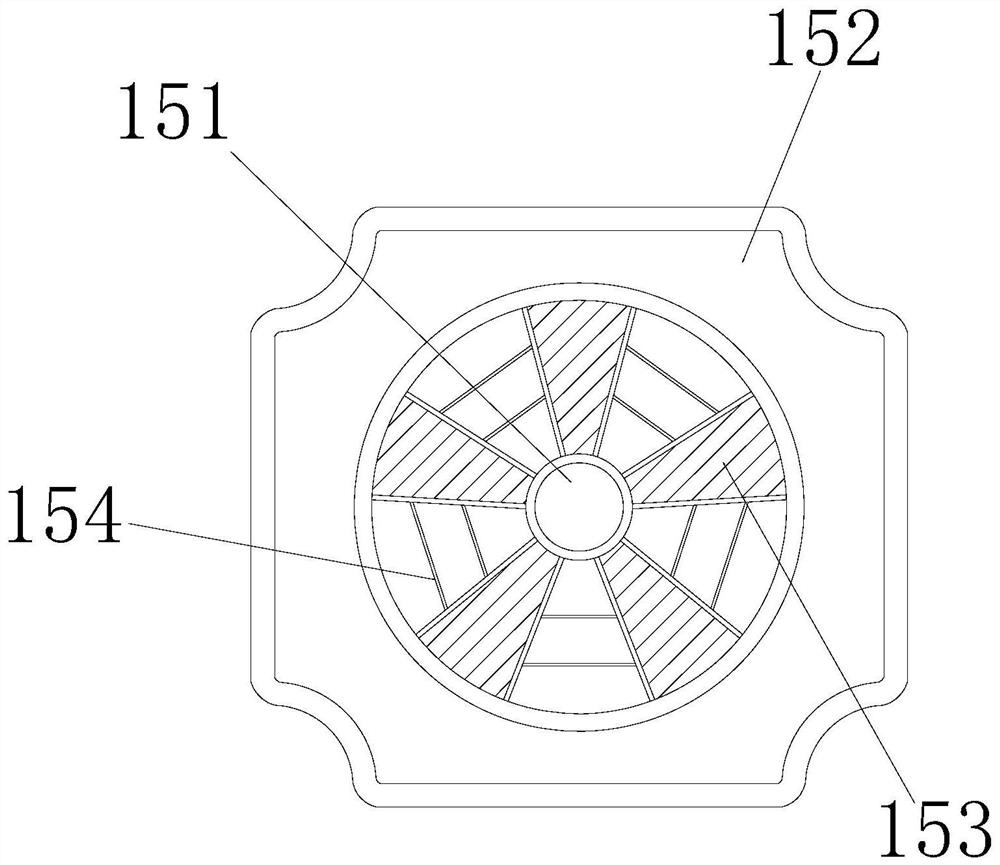

[0031] The invention provides an integrated variable speed drive for electric vehicles, the structure of which includes a body 1, a connecting cover 2, a rotating shaft 3, and a shaft sleeve 4, the left end of the body 1 is embedded and connected to the right end of the connecting cover 2, and the right end of the rotating shaft 3 is connected to the body 1. The left end is welded and connected. The right end of the shaft sleeve 4 is embedded and installed on the left end of the connecting cover 2. The body 1 includes a bearing 11, an electromagnetic coil 12, a fan blade 13, a connecting shaft 14, a heat dissipation cover 15, a rotor 16, and a sealing wall 17. , the inner side of the bearing 11 is connected with the outer side of the rotating shaft 3 with interference fit, the outer side of the electromagnetic coil 12 is welded and connected with the inner side of the sealing wall 17, the inner side of the fan blade 13...

Embodiment 2

[0039] as attached Figure 7 to attach Figure 9 Shown:

[0040] The present invention provides an integrated variable speed drive for an electric vehicle. The force plate 432 includes a connecting plate 321, a fixed sleeve 322, a sliding tube 323, a press-cut block 324, an elastic block 325, and a fixed wall 326. The inner side of the connecting plate 321 It is welded to the outer side of the fixed wall 326, the outer side of the fixed sleeve 322 is engaged with the inner side of the sliding tube 323, the outer side of the sliding tube 323 is movably engaged with the inner side of the sliding ring 433, and the outer side of the pressing block 324 is vertically installed on the fixed wall 326 inside, the outside of the elastic block 325 is embedded and connected with the inside of the fixed wall 326, the left end of the connecting plate 321 is embedded and connected with the right end of the installation block 431, and the press-cut block 324 is staggered and installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com