Method and device for preparing nano-powder by thermal cracking

A nano-powder, thermal cracking technology, applied in grain processing and other directions, can solve the problems of large equipment investment, slow steam production and large investment in steam mills, and achieve the effects of high energy utilization rate, high crushing intensity and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

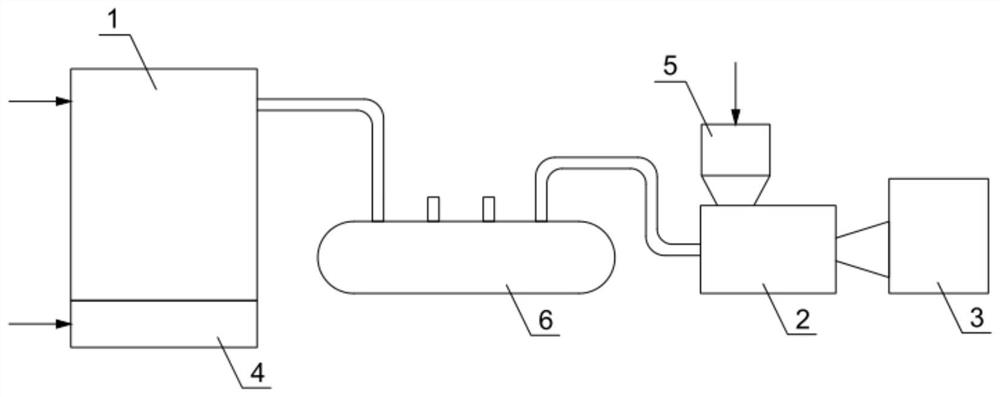

[0050] In order to solve various defects existing in the existing nano-powder processing equipment, the present invention provides a thermal cracking preparation device for nano-powder, such as figure 1 As shown, it includes: a superheated steam generator 1, a Laval jet device 2, and a pyrolysis reactor 3.

[0051] In this embodiment, the superheated steam generator 1 is used to generate superheated steam. Specifically, there is a heat medium in the superheated steam generator 1. The heat medium is heated by the heater 4 to store heat and energy. The heat medium The temperature of the medium can be heated to 400-650°C. The heater 4 is specifically a burner, and the natural gas is fed into the burner to burn, so as to heat the heat medium.

[0052] It should be noted that the heater 4 is not limited to the burner in this embodiment, and in other embodiments, heating methods such as electric heating can also be used.

[0053] In addition to the generator body, the superheated s...

Embodiment 2

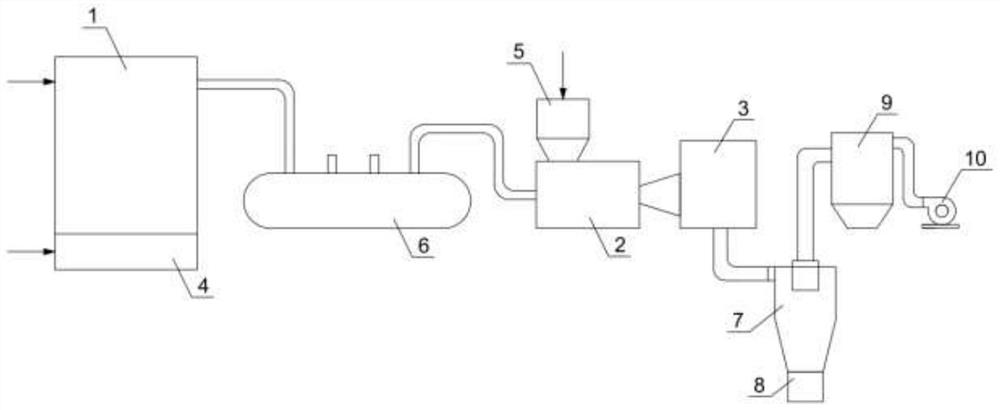

[0068] A device for preparing nanopowders by pyrolysis, such as figure 2 As shown, different from Embodiment 1, this embodiment also includes a sorting mechanism.

[0069] In Example 1, the 500-2000 mesh (25-6.5 μm) powder can form 8000-12500 mesh (1.6-1.0 μm) nanoscale powder after the continuous pyrolysis pulverization reaction in the pyrolysis reactor 3. The sorting mechanism in the embodiment is for further sorting and screening the powder produced in the pyrolysis reactor 3 .

[0070] In this embodiment, the sorting mechanism includes: a cyclone separator 7 , a powder buffer bin 8 , a sorting pulse dust collector 9 and a sorting exhaust fan 10 .

[0071] Specifically, such as figure 2 As shown, the cyclone separator 7 is connected to the bottom of the thermal cracking reactor 3 for sorting and separating the powder products discharged from the thermal cracking reactor, and the powder buffer storehouse 8 is connected to the cyclone separator The bottom of the cyclone ...

Embodiment 3

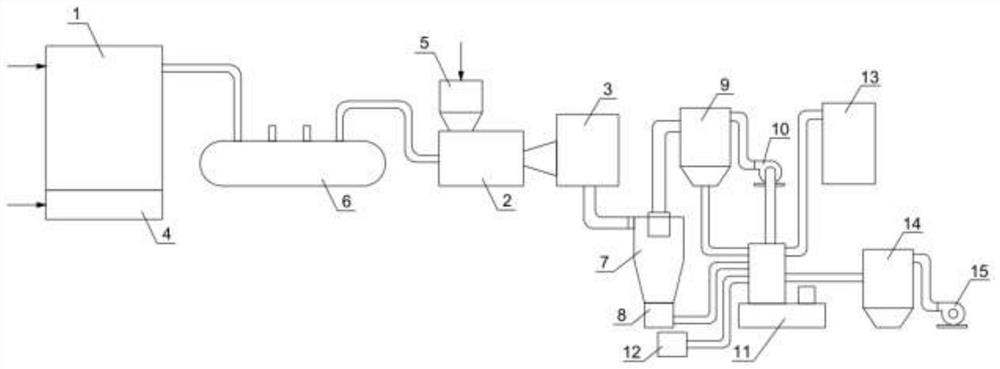

[0076] The device for preparing nano-powder by pyrolysis is different from Example 2 in that this embodiment also includes a drying and depolymerization mechanism. For some powders with strong water absorption and prone to agglomeration, they can be further processed through the drying and depolymerization mechanism. .

[0077] In this embodiment, the drying and deaggregating mechanism includes a honeycomb mill 11, which is connected to the powder buffer bin 8 and the sorting pulse dust collector 9 respectively, and the powder in the powder buffer bin 8, the sorting The 1# nano-powder in the pulse dust collector 9 and the dispersant in the dispersant tank 12 are transported to the honeycomb mill 11 according to the metering ratio for drying, depolymerization, and modification. Carry out hot air delivery, that is, the honeycomb mill 11 of this embodiment communicates with the sorting exhaust fan 10 .

[0078] It should be noted that the dispersant tank 12 in this embodiment al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com