A debuggable hydraulic rotor lamination tool

A technology for laminating tooling and rotors, which is applied in the manufacture of stator/rotor bodies, electromechanical devices, and cleaning methods using tools, etc. It can solve the problems of long production cycle, low production efficiency, and positioning size differences, and reduce the number of impurities, Improve cleanliness and ensure quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

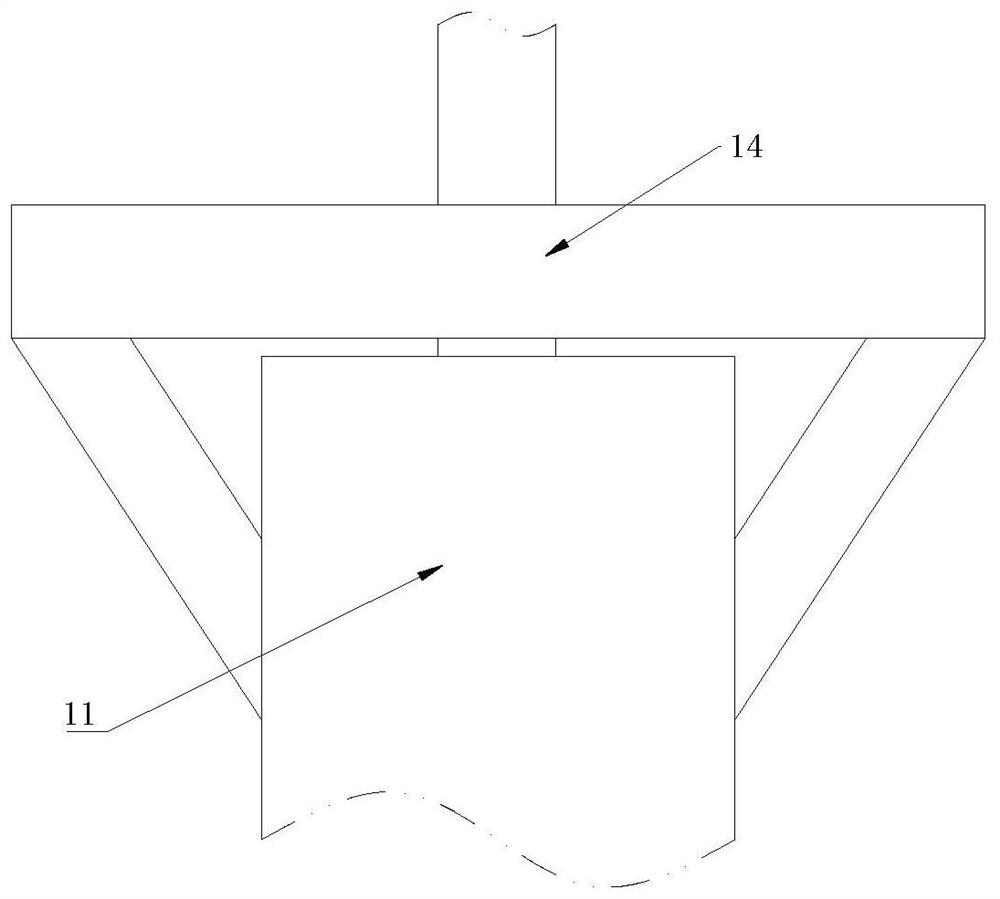

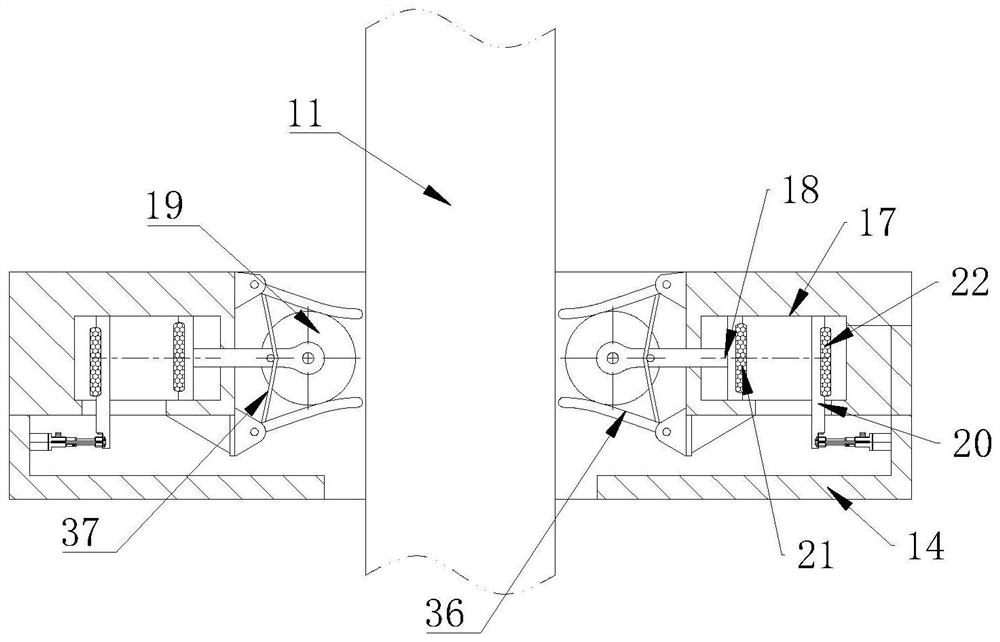

[0052] see Figure 2-5 As shown in the comparison example 1, as another embodiment of the present invention, a cleaning box 14 is fixed on the hydraulic cylinder 11; the hydraulic cylinder 11 is slidably connected with the cleaning box 14; the inner side of the cleaning box 14 The wall is provided with a plurality of groups of piston chambers 17; the position of the piston chamber 17 corresponds to the hydraulic cylinder 11; a piston rod 18 is slidably connected inside the piston chamber 17; Cleaning roller 19; a control plate 20 is slidably connected inside the piston cavity 17; an electric cylinder is installed on the inner wall of the cleaning box 14; the control plate 20 is fixedly connected with the output end of the electric cylinder; the piston rod 18 side A first magnet 21 is fixed on the wall; a second magnet 22 is fixed on the side wall of the control board 20; during use, when the hydraulic cylinder 11 outputs mechanical energy on the cleaning box 14, it is in the c...

Embodiment 3

[0062] see Image 6 As shown, compared with the above-mentioned embodiment, as another embodiment of the present invention, a plurality of groups of flexible friction cleaning sheets 38 are fixedly connected to the side walls of the cleaning bristles 36; Three elastic pull cords 39; by adding multiple sets of flexible friction cleaning sheets 38 to the side walls of the cleaning bristles 36, when the cleaning bristles 36 are in contact with the cleaning roller 19, the flexible friction cleaning sheets 38 are tightly pressed against the cleaning roller 19 On the side wall of the cleaning roller 19, the flexible friction cleaning sheet 38 extends into the side wall of the cleaning roller 19, where the cleaning bristles 36 are not easy to contact, so that after the side wall of the cleaning roller 19 is in contact with the cleaning bristles 36, it will be cleaned more cleanly.

[0063] The overall working principle is:

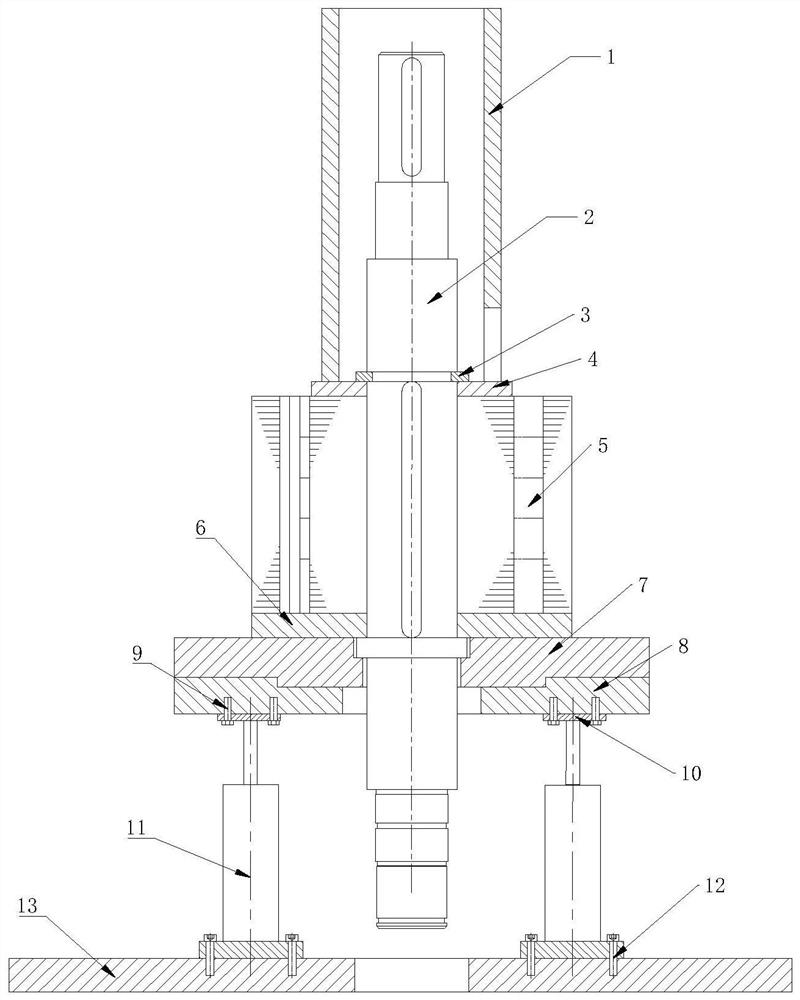

[0064] 1. Place the assembled stacking tool on the press t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com