Photosensitive resin composition, photosensitive resin film, multilayer printed wiring board, semiconductor package, and method for producing multilayer printed wiring board

A technology of photosensitive resin and composition, which is applied in the field of photosensitive resin composition, can solve the problems of a large amount of time and poor manufacturing efficiency, and achieve the effects of good efficiency, excellent electrical insulation reliability, and excellent crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0345] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to these Examples.

[0346] In addition, the photosensitive resin composition obtained from Examples 1-3 and Comparative Examples 1-2 evaluated the characteristic by the method shown below.

[0347] [1. Evaluation of through-hole resolution]

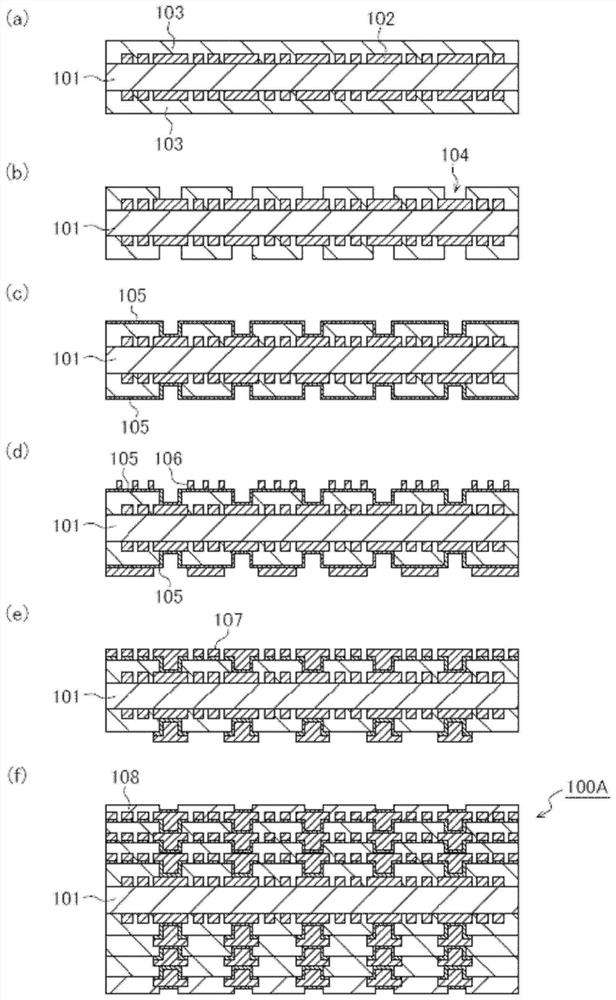

[0348] (1-1) Production of laminated body for evaluation

[0349] A substrate for a printed wiring board (manufactured by Hitachi Chemical Co., Ltd., manufactured by Hitachi Chemical Co., Ltd., manufactured by laminating copper foil with a thickness of 12 μm on a glass epoxy substrate) was treated with a roughening pretreatment solution (manufactured by MEC Corporation, trade name "CZ-8100"). The surface of the copper foil with the trade name "MCL-E-679") was treated, washed with water, and dried to obtain a substrate for a printed wiring board subjected to a pre-roughening treatment. Next, the protective film was peeled and rem...

Synthetic example 1

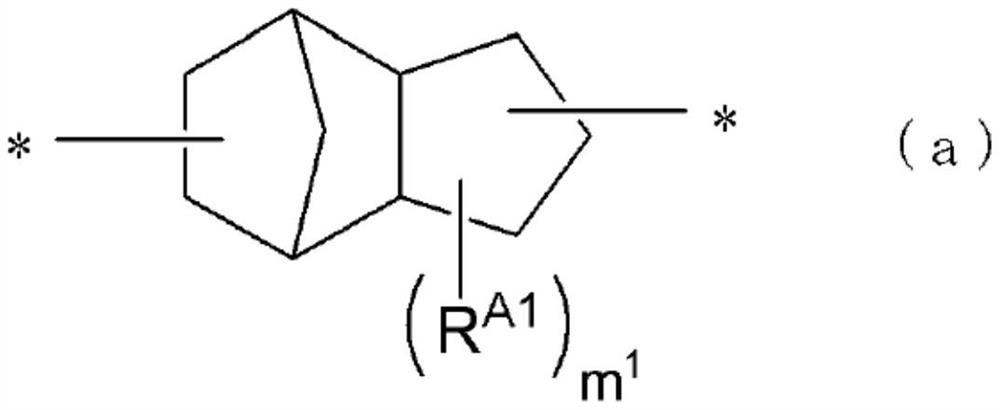

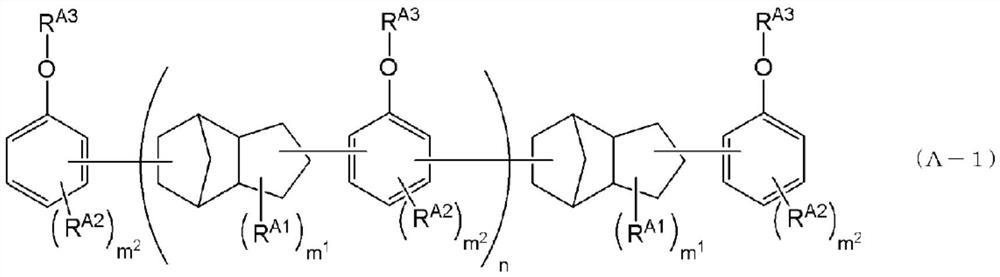

[0376] Synthesis of acid-modified epoxy derivative 1 [(A1-1) component] containing ethylenically unsaturated group and alicyclic skeleton

[0377] Add 350 parts by mass of dicyclopentadiene type epoxy resin ("XD-1000" produced by Nippon Kayaku Co., Ltd., epoxy equivalent 252g / eq, softening point 74.2 ° C, equivalent to (a1) composition, by the above general formula (a1-1) represents. The number of ring-forming carbon atoms of the alicyclic skeleton: 10), 70 parts by mass of acrylic acid (corresponding to component (a2)), 0.5 parts by mass of methylhydroquinone, and 120 parts by mass of carbitol acetic acid The ester was reacted by heating to 90°C with stirring to dissolve the mixture.

[0378] Next, the obtained solution was cooled to 60 degreeC, 2 mass parts of triphenylphosphine were added, it heated at 100 degreeC, and it reacted until the acid value of a solution became 1 mgKOH / g. 98 mass parts of tetrahydrophthalic anhydrides (corresponding to (a3) component) and 85 m...

Synthetic example 2

[0380] Synthesis of acid-modified epoxy derivative 2 [(A1-1) component] containing ethylenically unsaturated group and alicyclic skeleton

[0381] Add 350 parts by mass of dicyclopentadiene type epoxy resin ("EPICLON (registered trademark) HP-7200" produced by DIC Corporation, epoxy equivalent 254~264g / eq, softening point 56~66 ℃, equivalent to (a1 ) component, represented by the above general formula (a1-1). The number of ring-forming carbon atoms in the alicyclic skeleton: 10), 70 parts by mass of acrylic acid (equivalent to the component (a2)), 0.5 parts by mass of methylhydroquinone, 120 parts by mass Parts by mass of carbitol acetate were reacted by heating to 90° C. and stirring, thereby dissolving the mixture.

[0382] Next, the obtained solution was cooled to 60 degreeC, 2 mass parts of triphenylphosphine were added, it heated at 100 degreeC, and it reacted until the acid value of a solution became 1 mgKOH / g. 98 mass parts of tetrahydrophthalic anhydrides (correspond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com