Water outlet control device of coffee machine

A water outlet control device, coffee machine technology, applied in beverage preparation devices, home appliances, applications, etc., can solve the problems of slow water outlet speed, long waiting time, difference in coffee taste and taste, etc., to achieve accurate temperature control and precise water intake , The effect of shortening the heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

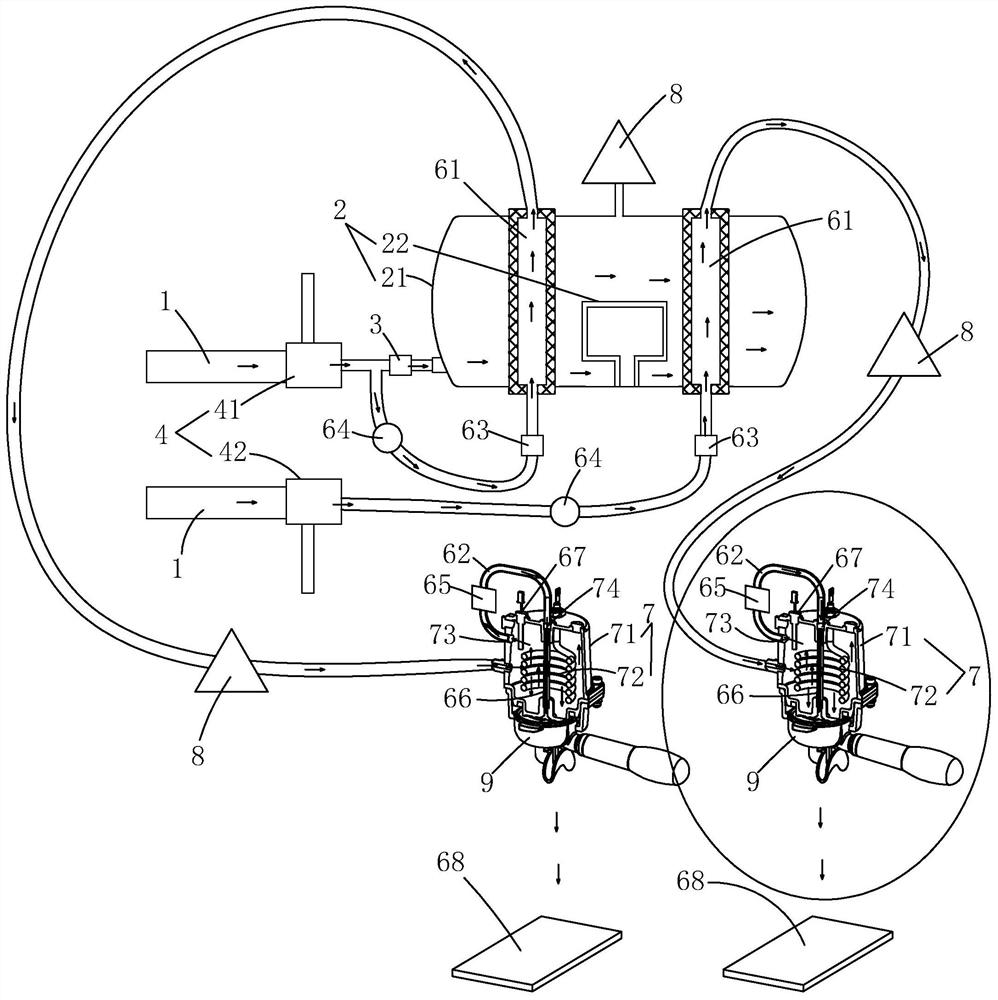

[0031] Example, combined with Figure 1 to Figure 4 As shown, a coffee machine includes a casing (not shown in the figure), a touch screen 10, a water inlet pipeline 1, a first heating inner tank 2, a first solenoid valve 3, two variable pressure water pumps 4, and a circuit board 5. Two hot water circulation heating modules 6, a pressure sensor 8 and a coffee funnel 9, the touch screen 10 is arranged on the casing, the touch screen 10 is electrically connected to the circuit board, and the two variable pressure water pumps 4 include a first The water pump 41 and the second water pump 42.

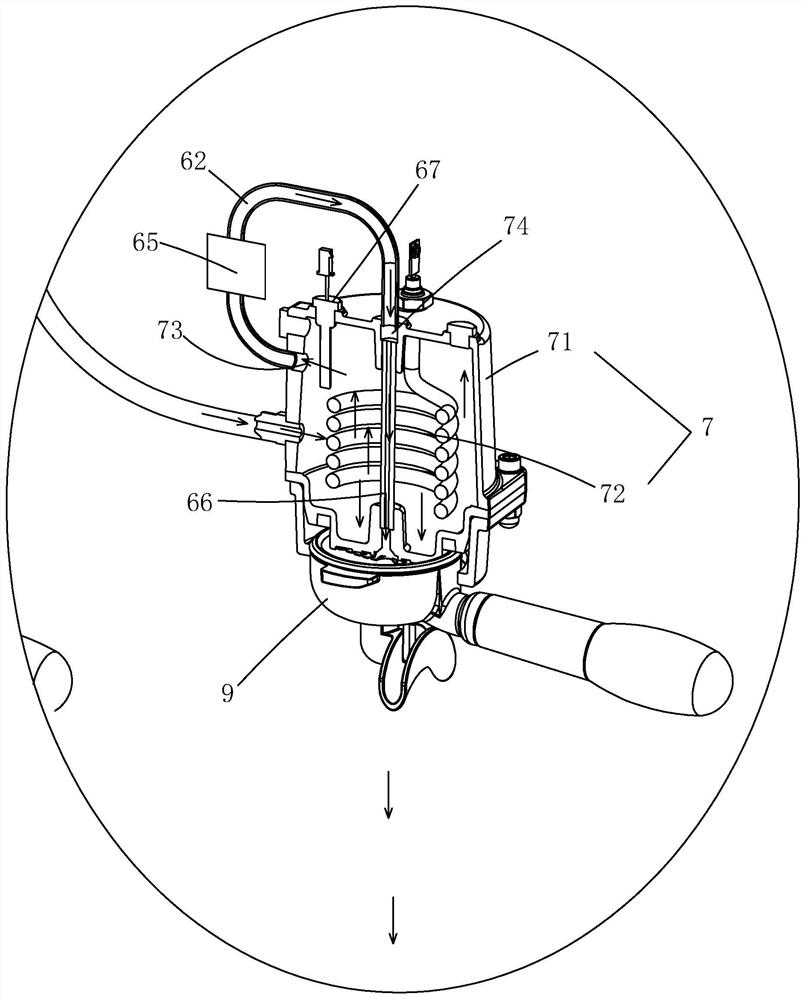

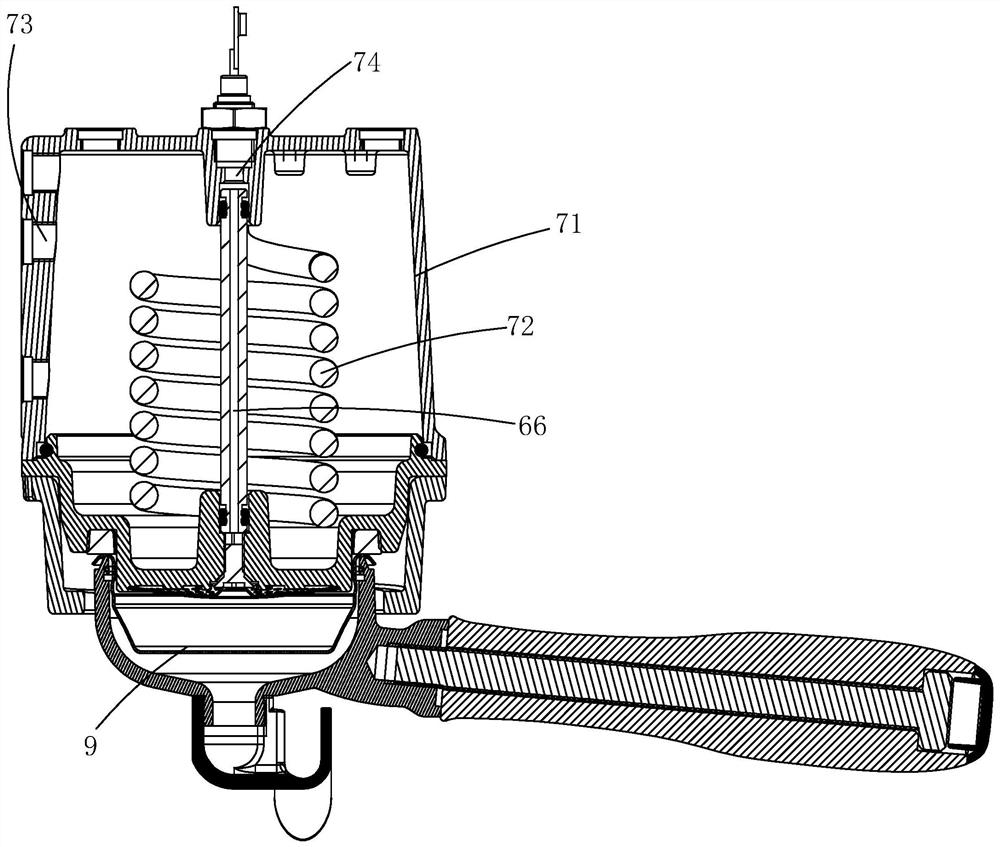

[0032] The hot water circulation heating module 6 includes a water storage tank 61, a second heating liner 7, a hot water return pipe 62, a second solenoid valve 63, a flow meter 64, a third solenoid valve 65, a drain pipe 66, and a thermocouple 67 , water tray and load cell 68.

[0033] The first heating liner 2 includes a first water tank 21 and a first heating body 22, the first water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com