Cooking equipment temperature measurement control method and cooking equipment

A technology of cooking equipment and control method, applied in the field of kitchen utensils, can solve problems such as inaccurate control, inaccurate temperature sensing, and inability of a temperature sensor to accurately sense the actual temperature of cooking objects, so as to achieve accurate temperature measurement and reduce measurement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

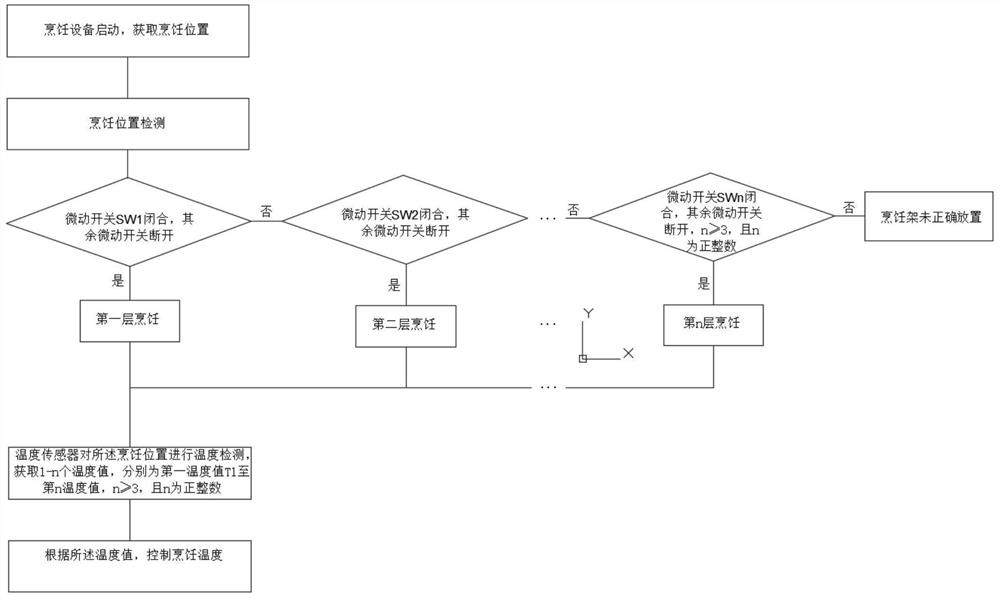

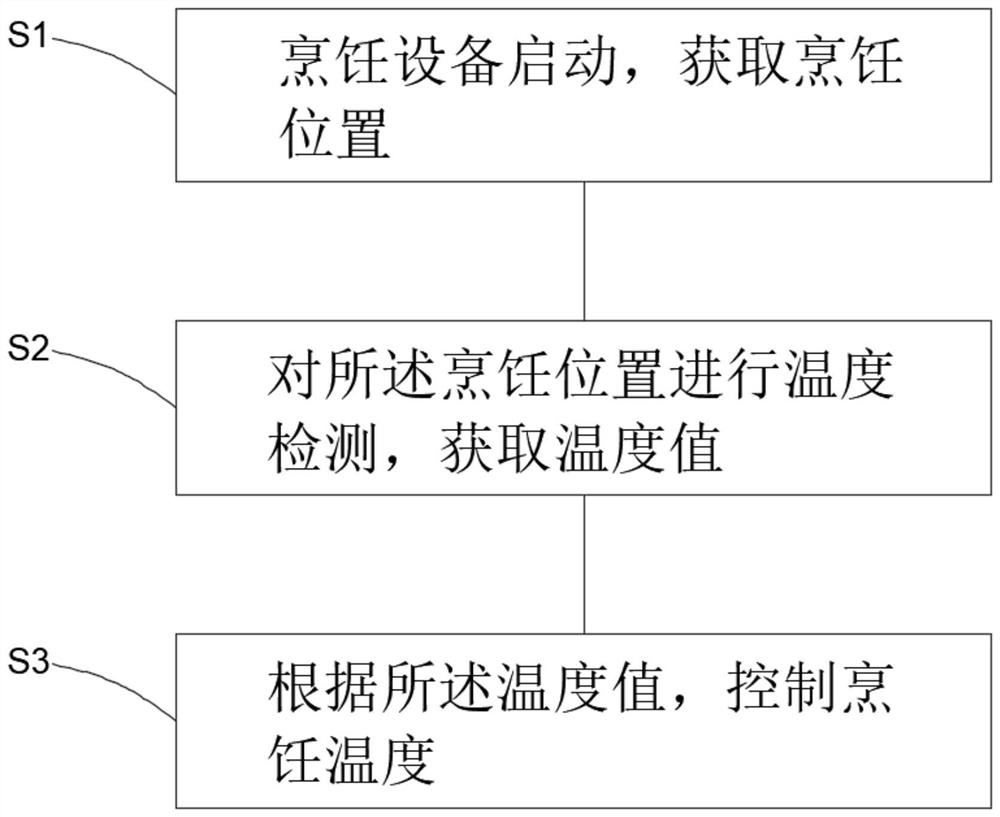

[0052] A method for temperature measurement and control of cooking equipment, comprising:

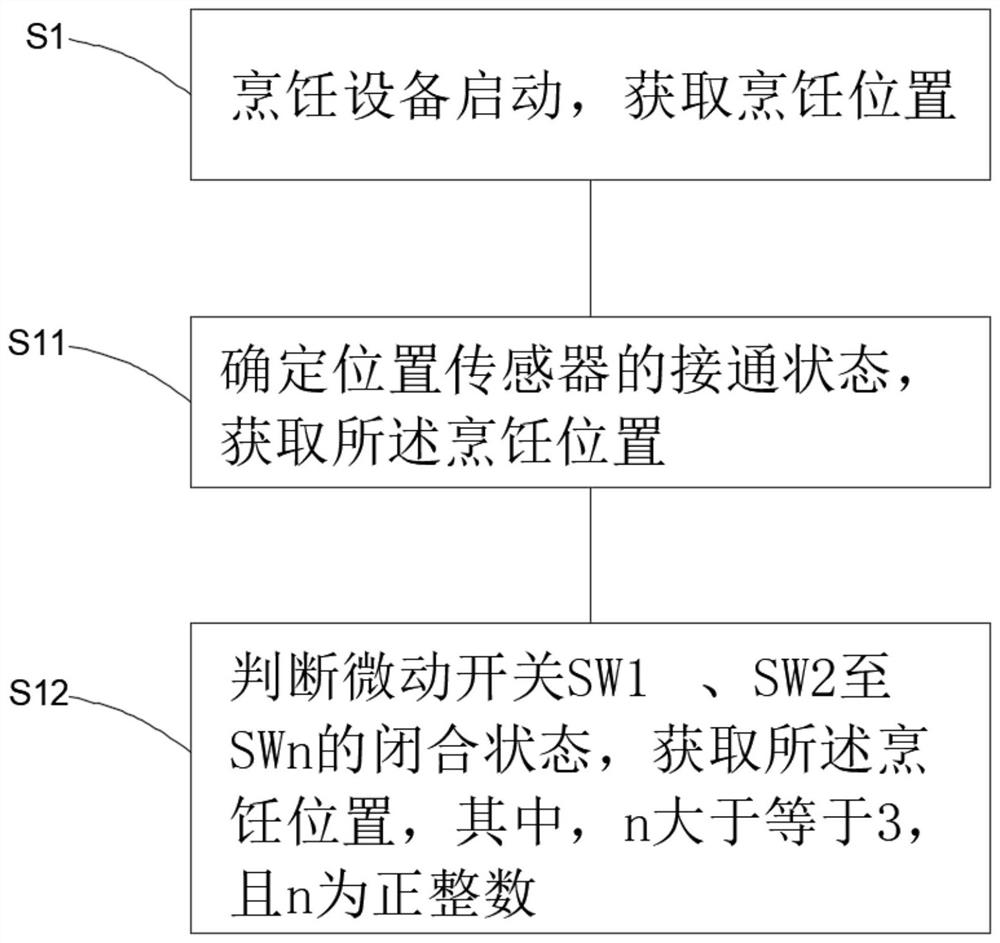

[0053] S1: Start the cooking device and obtain the cooking position;

[0054] S11: Determine the on state of the position sensor, and obtain the cooking position.

[0055] Including n microswitches, in this embodiment, including 3 microswitches, see image 3 , are respectively micro switch SW1, micro switch SW2 and micro switch SW3, wherein the three micro switches belong to different cooking positions, therefore, through the three micro switches, the way of temperature detection in different cooking positions is realized, Among them, micro switch SW1, micro switch SW2 and micro switch SW3 are connected in parallel on three terminals, wherein micro switch SW1 is connected between terminal 1 and terminal 2; micro switch SW2 is connected between terminal 2 and terminal 3 Between; Micro switch SW3 is connected between terminal 1 and terminal 3.

[0056] Specifically, the following judgm...

Embodiment 2

[0085] see Figure 7 , Figure 8 and Figure 9 As shown, a cooking device according to a cooking device temperature measurement control method in Example 1 includes a cooking device body 1, a control module 6, a cooking support 2, a temperature measuring component 3, a heating component 5 and an induction component 6; The temperature component 3 is arranged on the cooking frame for detecting temperature value signals in different regions. The induction component 6 is arranged on the cooking support 2. When the cooking frame is placed on the cooking support 2, the induction component 6 is closed to obtain a closing signal. It is used to determine the cooking position information of the cooking object; the control module 6 controls the working state of the heating assembly 5 according to the temperature value signal and the closing signal.

[0086] The detection is performed according to different cooking positions, and the detection is carried out in partitions for the cookin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com