Cleaning mechanism and cleaning equipment

A technology for cleaning mechanism and cleaning equipment, applied in the field of cleaning, can solve the problems of easy damage and low controllability of tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

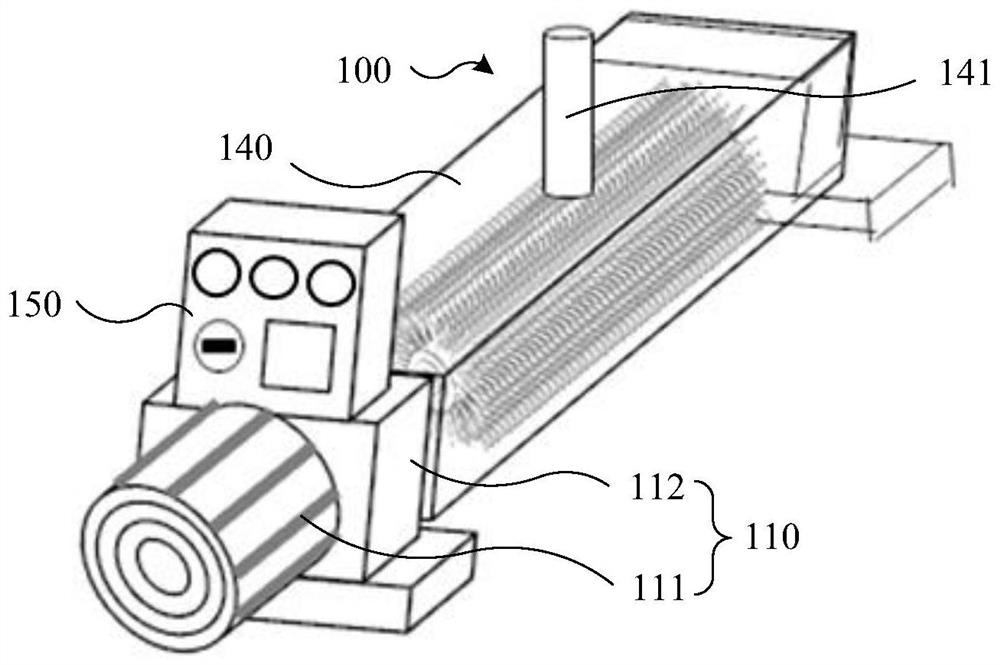

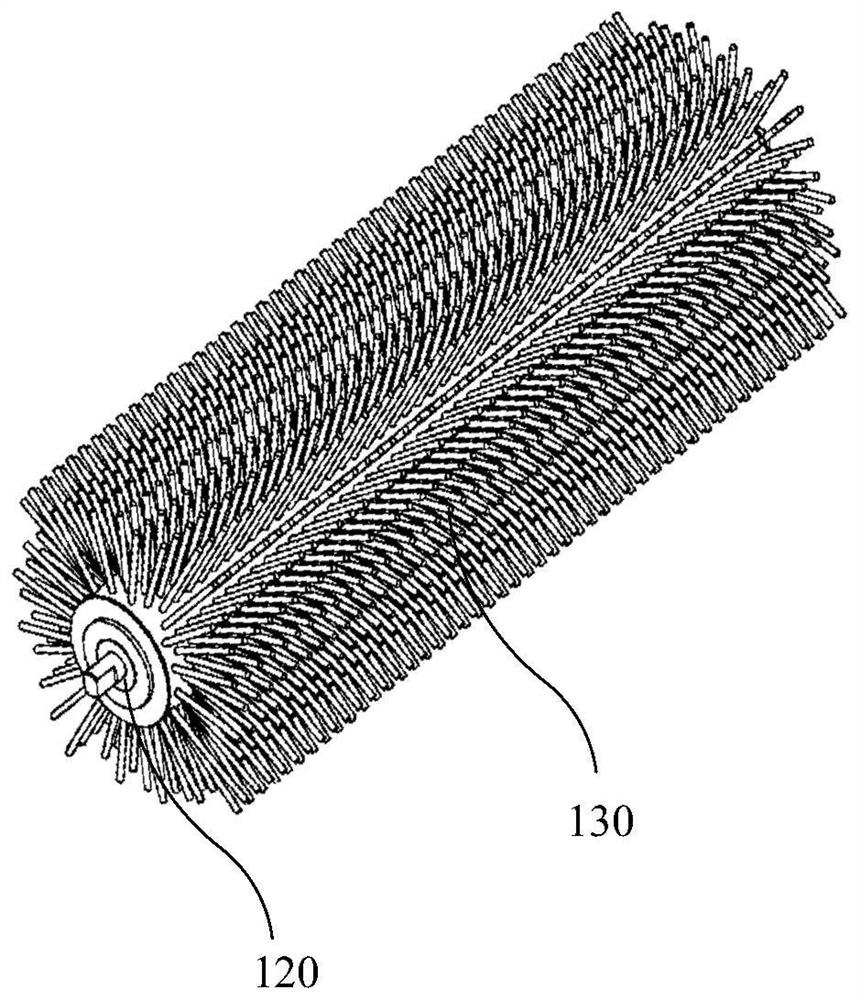

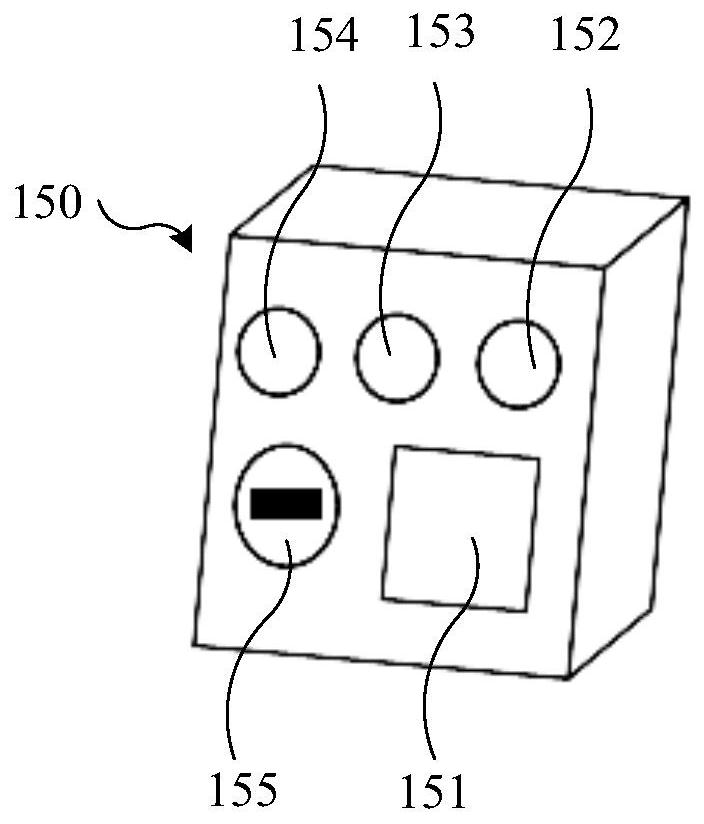

[0054] figure 1 It is a schematic structural diagram of the cleaning mechanism provided in Embodiment 1 of the present application. figure 2 An assembly drawing of the rotating part and cleaning part of the cleaning mechanism provided in Embodiment 1 of the present application. image 3 It is a schematic structural diagram of the operation panel of the cleaning mechanism provided in Embodiment 1 of the present application.

[0055] refer to Figure 1 to Figure 3 As shown, the cleaning mechanism 100 provided in a possible embodiment of the present application includes a driving member 110, a rotating member 120 and a cleaning member 130, the rotating member 120 is connected with the driving member 110, and the cleaning member 130 is arranged on the rotating member 120; The outer cover of the component 120 is provided with a transparent cover 140 , and an accommodating cavity is formed between the transparent cover 140 and the rotating component 120 .

[0056] The cleaning m...

Embodiment 2

[0074] Figure 4 It is a schematic structural diagram of the cleaning equipment provided in Example 2 of the present application. Figure 5 It is a schematic structural diagram of the conveying assembly (including the stopper) of the cleaning device provided in Embodiment 2 of the present application. Image 6 It is a schematic structural diagram of the conveying assembly (without the stopper) of the cleaning device provided in Embodiment 2 of the present application. Figure 7 It is a schematic structural diagram of the cutterhead (including cutters) of the cleaning device provided in Example 2 of the present application. Figure 8 It is a schematic structural diagram of the limiting member of the cleaning equipment provided in the second embodiment of the present application.

[0075] refer to Figure 4 to Figure 8As shown, on the basis of the first embodiment, a possible embodiment of the present application provides a cleaning device configured with the cleaning mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com