Intelligent repairing device for paint surface defects of automobile body covering part

A car body and intelligent repair technology, which is applied in the direction of spraying device, grinding drive device, vehicle maintenance/repair, etc., can solve the problems of cumbersome procedures, low efficiency of single-point repair, high labor intensity, etc., and reduce the demand for personnel and labor Technical level requirements, improvement of repair efficiency and repair quality level, and the effect of improving consistency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

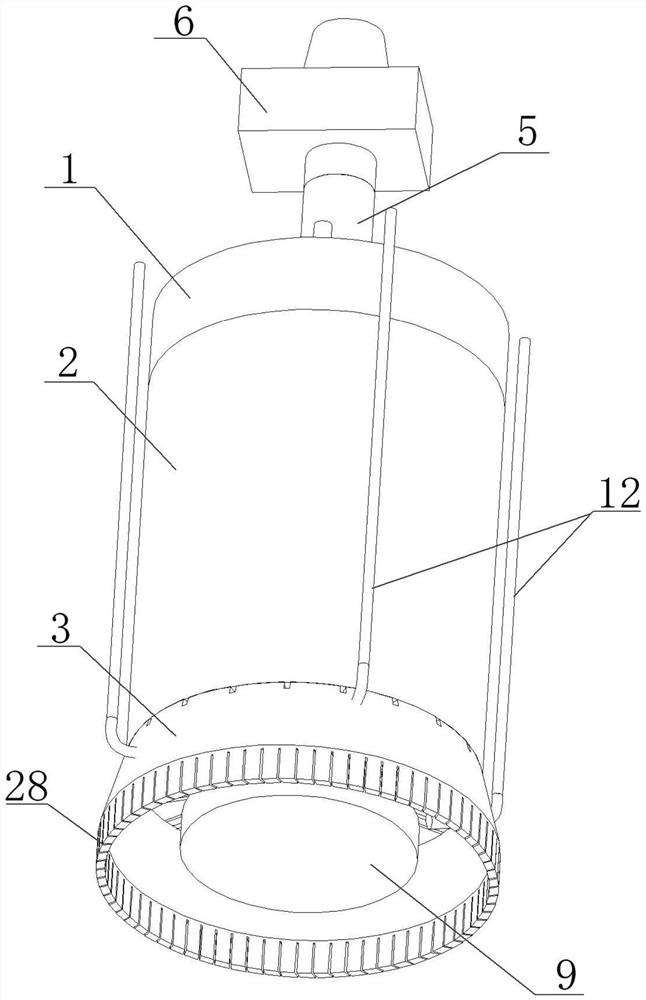

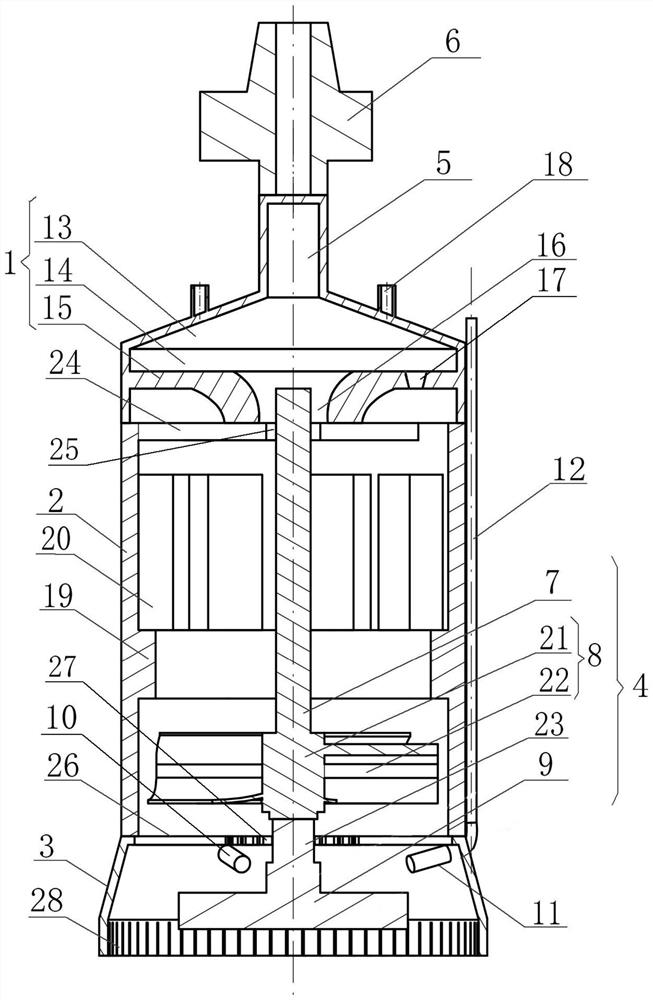

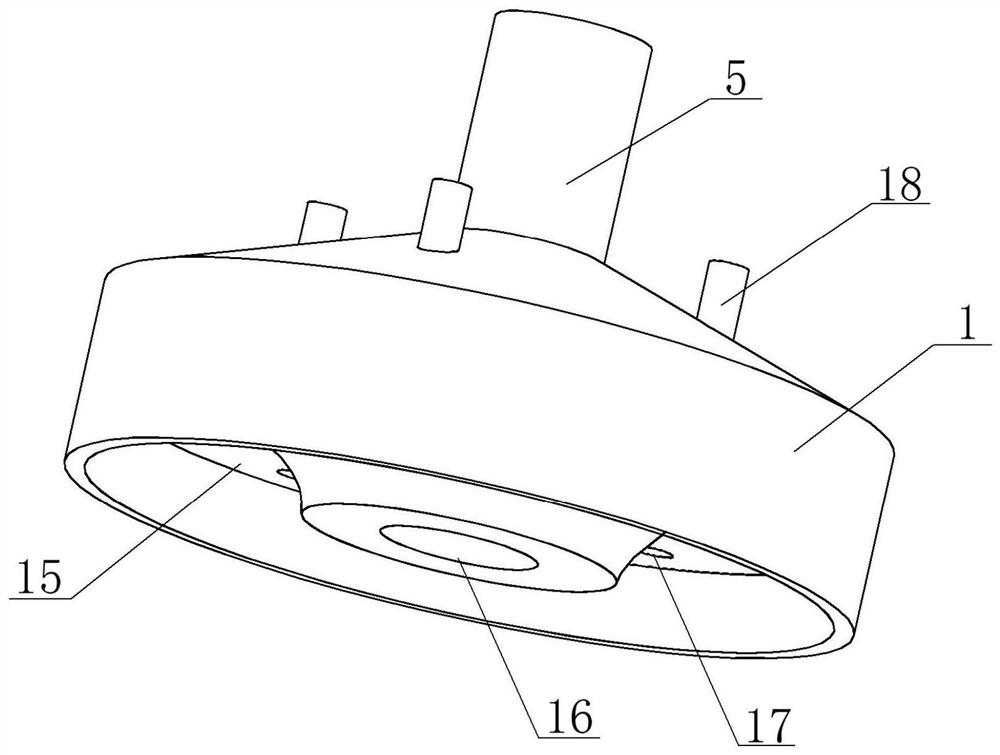

[0037] see Figure 1-9 Shown:

[0038]The invention provides an intelligent repairing device for paint surface defects of automobile body panels, which includes an air duct device 1, a main casing 2, a grinding and polishing spray chamber 3, a turbine grinding and polishing device 4 and a control system. The air duct device 1 is designed On the upper part of the main housing 2, the grinding and polishing spraying chamber 3 is arranged at the lower part of the main housing 2, and the air duct device 1, the main housing 2 and the grinding and polishing coating chamber 3 are connected inside; the upper part of the air duct device 1 is provided with an air inlet channel 5 , the air inlet channel 5 is provided with a flow control valve 6, the flow control valve 6 has its own flow sensor, the flow control valve 6 is connected to the control system through a line, and the flow control valve 6 is connected to the air compression pump; the turbine grinding and polishing device 4 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com