Aviation aircraft environment control system humidity control device maintenance method

A control system and humidity control technology, applied in aircraft maintenance, aircraft parts, transportation and packaging, etc., can solve problems such as the impact of the entire aircraft maintenance and support work, unfavorable combat training and combat effectiveness, and wire mesh B222 holes. The effect of enhancing the comprehensive support capability of equipment, improving the timeliness of equipment delivery, and enhancing operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

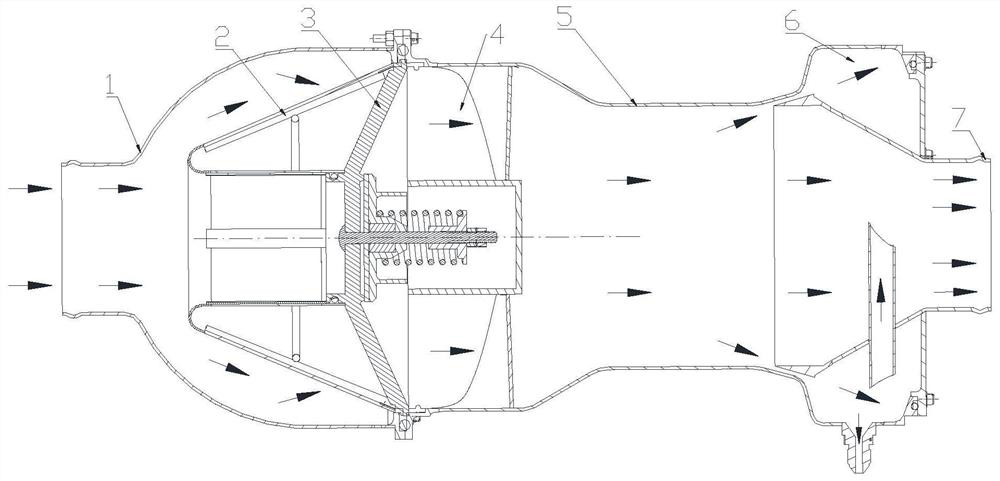

[0047] like Figure 1 to Figure 9 Shown, a kind of air vehicle environmental control system humidity control device maintenance method, concrete steps are as follows:

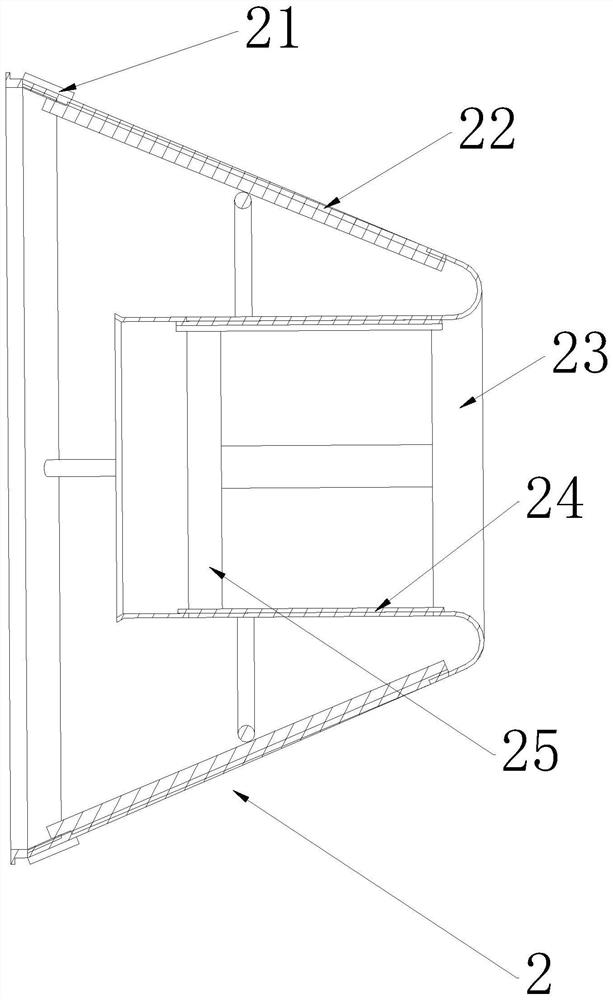

[0048] (1) Reference figure 2 , Remove the liner A21 and liner B25 on the condenser 2.

[0049] (2) Reference figure 1 and figure 2 , take off the cone net 22 and the cylinder net 24 with a polishing machine, and grind and polish the welding spot positions of the flange 236 and the fairing 231. To facilitate re-welding after maintenance.

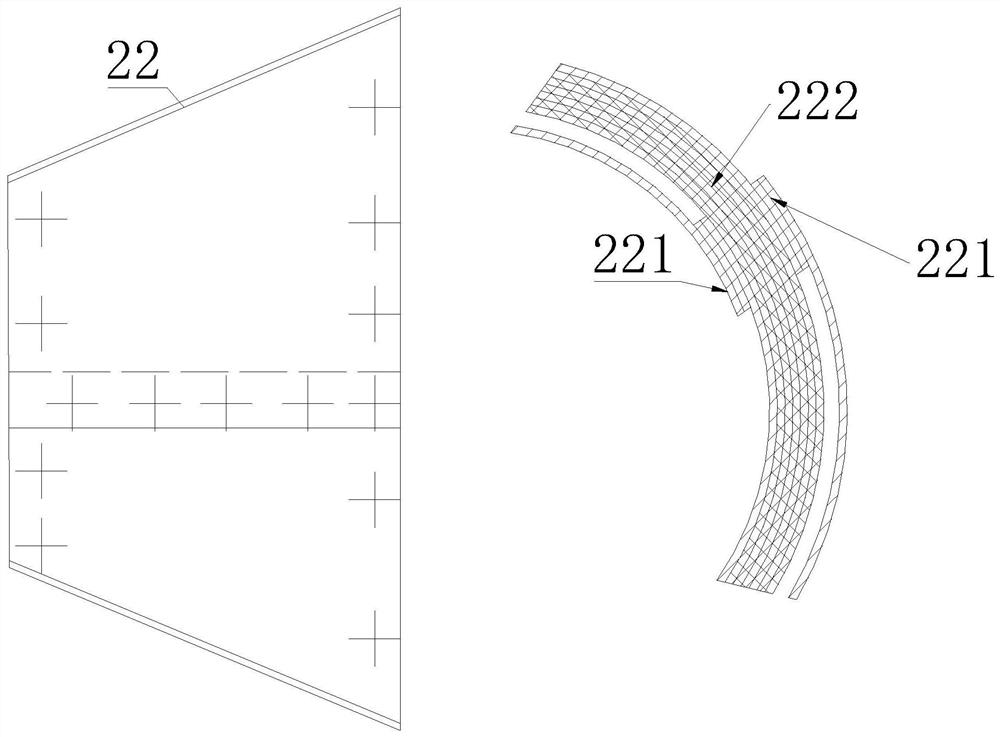

[0050] (3) Use the stainless steel strip with the same material and thickness as the wire mesh A221, cut out the sheet metal parts A and B with an expansion angle of 180°, corresponding outer diameters of 182.32mm and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com