Conveying equipment for producing dairy products containing fruit particles and conveying method

A technology for conveying equipment and dairy products, applied in chemical instruments and methods, mixers with rotary stirring devices, transportation and packaging, etc., can solve the problems of inability to continue conveying and filling, affecting work efficiency, and pipeline blockage, etc. To achieve the effect of reducing the number of placements, improving work efficiency, and reducing space occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

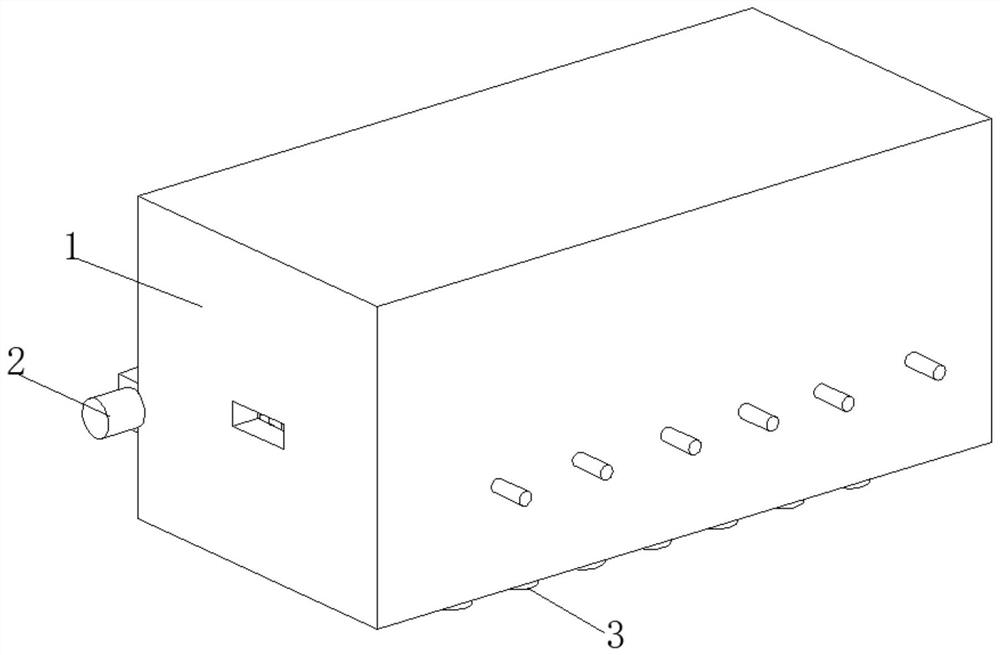

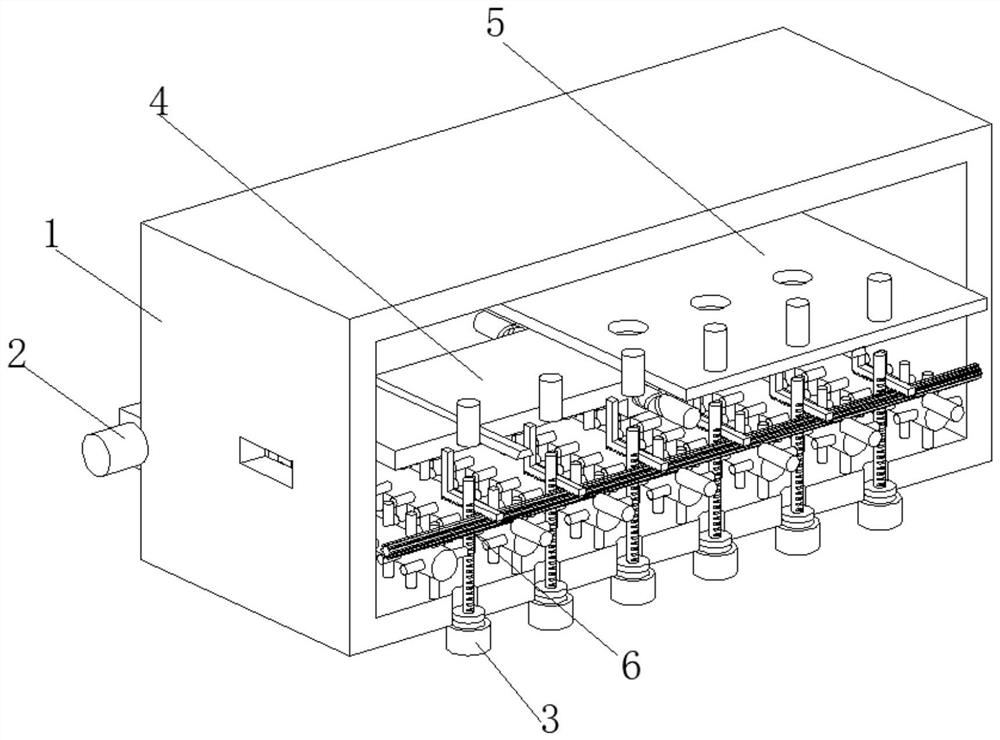

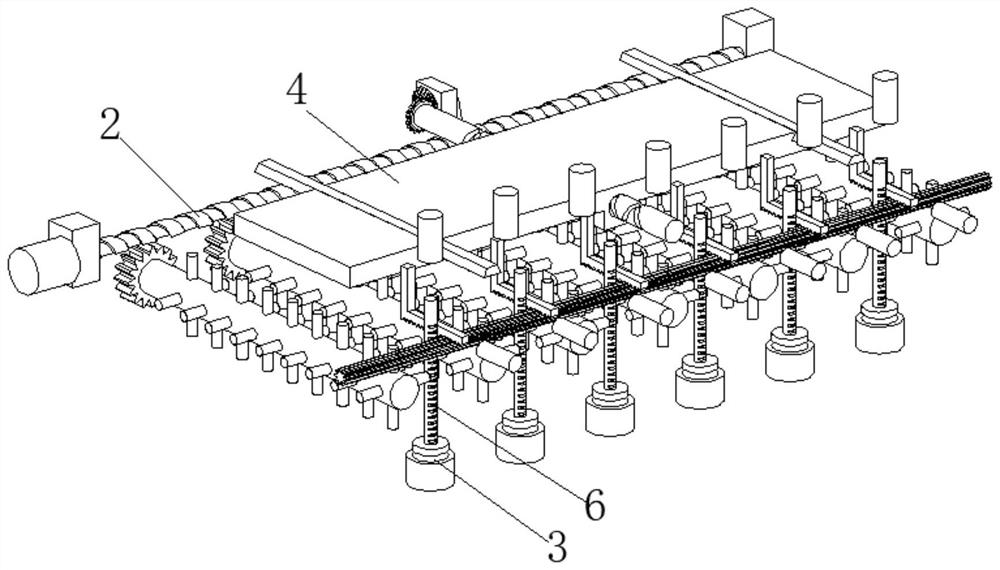

[0038] A kind of conveying equipment and conveying method for the production of dairy products containing fruit particles, such as Figure 1-Figure 6 As shown, the box body 1 is included, the left side of the box body 1 is provided with a stirring mechanism 2, the bottom of the box body 1 is connected with a discharge pipe 3, the inner wall of the box body 1 is welded with a baffle plate 5, and the bottom of the baffle plate 5 is provided with a The feeding mechanism 4 is provided with a dredging mechanism 6 on the right side of the feeding mechanism 4; the stirring mechanism 2 stirs the fruit in the beverage and drives the feeding mechanism 4 to pour the fruit into the beverage intermittently and triggers the dredging mechanism 6 to move, and the dredging mechanism 6 Clean up the excess fruit in the pipeline after conveying and canning. Through the cooperative operation of the stirring mechanism 2, the feeding mechanism 4 and the dredging mechanism 6, the automatic dredging of...

Embodiment 2

[0045] Such as Figure 6-Figure 7 As shown, the top of the slide plate 41 is slidably connected to the bottom of the baffle plate 5, the top of the clip bar 42 is welded and fixed to the bottom of the baffle plate 5, the left end of the screw rod 43 is welded and fixed to the axis of the second bevel gear 272, and the screw rod The surface of 43 is rotatably connected with the inner wall of the box body 1, and the fruit grains can be fed intermittently through the feeding mechanism 4 to prevent the fruit grains from entering too much at one time, which will cause the fruit grains in the beverage to greatly exceed the standard and increase the production cost. And adding fruit pieces intermittently can facilitate stirring to achieve a more uniform mixing of fruit pieces.

[0046] It is worth noting that the dredging mechanism 6 includes a rack 61, the surface of the rack 61 is engaged with a transmission gear 62, the surface of the transmission gear 62 is engaged with a tooth c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com