Efficient contact type anaerobic reactor and method for treating wastewater

An anaerobic reactor and contact technology, applied in anaerobic digestion treatment, processing wastewater treatment, etc., can solve the problems affecting the stable operation of the system, poor continuous operation performance, and increased SS of effluent, so as to increase the amount of biogas produced, Reduce silt, reduce the effect of effluent SS

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

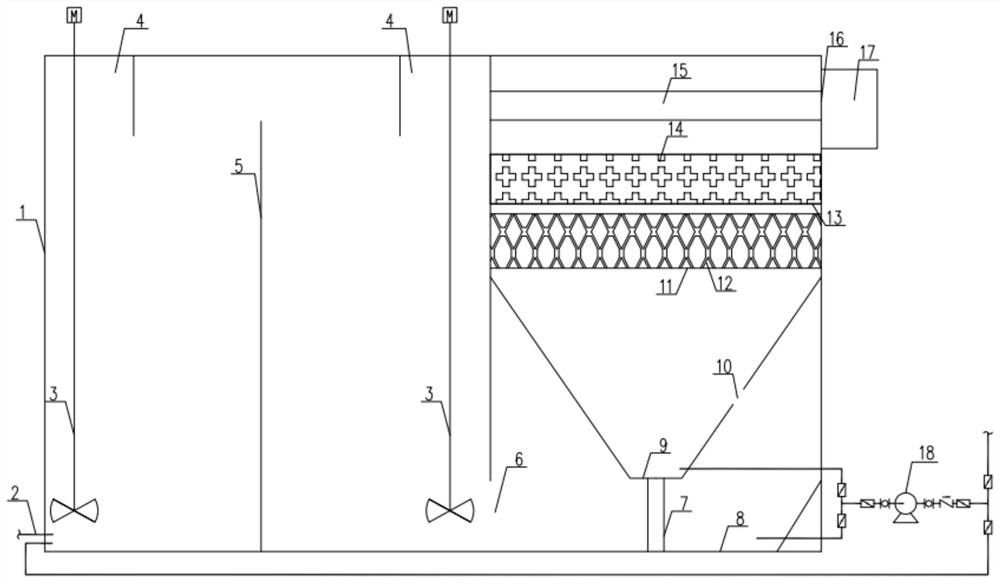

[0034] A high-efficiency contact anaerobic reactor, such as figure 1As shown, it includes an anaerobic reactor main body 1, the bottom of the anaerobic reactor main body 1 is provided with a water inlet pipe 2, and the anaerobic reactor main body 1 includes a reaction zone at the front end of the anaerobic reactor and a rear end The separation zone, the reaction zone and the separation zone are connected through the water passing zone 6, the reaction zone is composed of two reaction chambers connected in series, and each reaction chamber is provided with a mechanical stirring device 3 for separating waste water and anaerobic sewage The mud is stirred and mixed evenly, which is convenient for full reaction; the upper part of each reaction chamber is provided with a gas collection chamber 4, which is used to collect the biogas generated by anaerobic reaction; the two reaction chambers are separated by a retaining wall 5; the separation area is separated by The support 7 is provi...

Embodiment 2

[0038] A method utilizing the high-efficiency contact anaerobic reactor described in embodiment 1 to treat waste water, comprising steps as follows:

[0039] The wastewater to be treated enters the anaerobic reactor main body 1 through the water inlet pipe 2, and the reaction zone is provided with anaerobic sludge. The wastewater is stirred by the mechanical stirring device 3, so that the wastewater and the anaerobic sludge are evenly mixed with each other, and the anaerobic sludge The mud and the waste water are completely in contact, and the generated biogas rises and is collected in the gas collection chamber 4. The waste water passes from the water passing area 6 to the separation area at the rear end, and the sludge is concentrated in the primary mud collection area 8 through natural settlement, and is returned by the sludge pump 18. To the front end of the anaerobic reactor main body 1 or discharged to the sludge treatment system; the supernatant enters the built-in secon...

Embodiment 3

[0041] As described in Example 1, the difference is:

[0042] The packing 14 is an inclined tube, the material is polypropylene, the inclination angle is set to 75°, and the vertical height of the packing 14 is 1500mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com