Method for extracting and separating liquiritin and glycyrrhizic acid

A technology for liquiritin and glycyrrhizic acid, which is applied in the field of extraction and separation of liquiritin and glycyrrhizic acid, can solve problems such as difficult separation of target products, and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

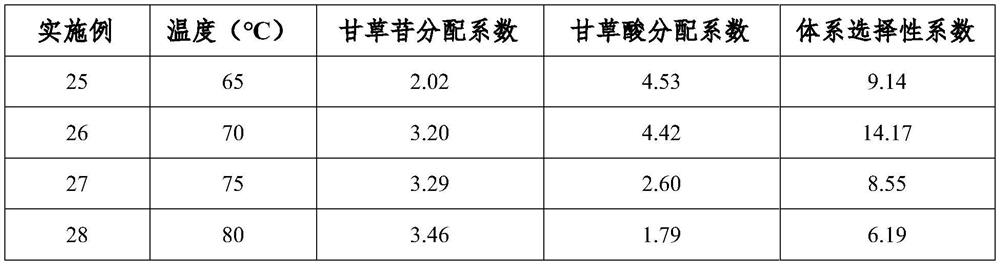

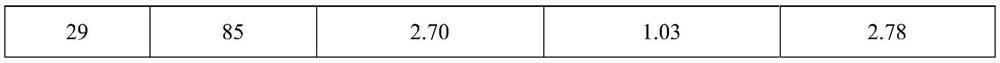

[0034] The licorice was extracted by the method of the above step S1. In Examples 1-5, other extraction conditions were the same, specifically: solid-liquid ratio 1g:40mL, extraction temperature 50°C, extraction time 30min, the difference was that the concentration of the ionic liquid was different . After the extraction, the extraction effects of liquiritin and glycyrrhizic acid were tested respectively, as shown in Table 1.

[0035] Table 1 Effect of different concentrations of ionic liquids on the extraction rate of liquiritin and glycyrrhizic acid

[0036] Example Ionic liquid concentration (%) Extraction rate of liquiritin (mg / g) Extraction rate of glycyrrhizic acid (mg / g) 1 20 5.52 15.00 2 40 5.71 15.30 3 50 5.79 19.82 4 60 6.61 25.04 5 80 6.22 18.79

Embodiment 6-10

[0038] Glycyrrhizae was extracted by the method of the above step S1. In Examples 6-10, other extraction conditions were the same, specifically: ionic liquid concentration 60%, extraction temperature 50°C, extraction time 30 minutes, the difference was that the solid-liquid ratio was different. After the extraction, the extraction effects of liquiritin and glycyrrhizic acid were tested respectively, as shown in Table 2.

[0039] The influence of table 2 different solid-liquid ratios on the extraction rate of liquiritin and glycyrrhizic acid

[0040] Example Solid to liquid ratio (g / ml) Extraction rate of liquiritin (mg / g) Extraction rate of glycyrrhizic acid (mg / g) 6 1:100 7.81 25.47 7 1:50 11.27 25.58 8 1:40 8.10 20.38 9 1:25 7.21 16.46 10 1:20 7.13 14.30

Embodiment 11-15

[0042] Using the method of the above step S1, the licorice is extracted. In Examples 11-15, the other conditions are the same, specifically: the concentration of the ionic liquid is 60%, the solid-liquid ratio is 1g:50mL, and the extraction time is 30min. The difference is that the extraction The temperature is different. After the extraction, the extraction effects of liquiritin and glycyrrhizic acid were tested respectively, as shown in Table 3.

[0043] Table 3 Effects of different extraction temperatures on the extraction rate of liquiritin and glycyrrhizic acid

[0044] Example temperature(℃) Extraction rate of liquiritin (mg / g) Extraction rate of glycyrrhizic acid (mg / g) 11 40 9.41 23.33 12 45 10.78 23.94 13 50 11.22 24.89 14 55 9.65 28.29 15 60 8.61 26.78

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com