A kind of biological protein/nano rust inhibitor/polyurethane composite coating and preparation method

A biological protein and composite coating technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of accelerating the corrosion of metal substrates, destroying the adhesion and impermeability of coatings, and achieving enhanced barrier properties, The effect of excellent mechanical properties and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

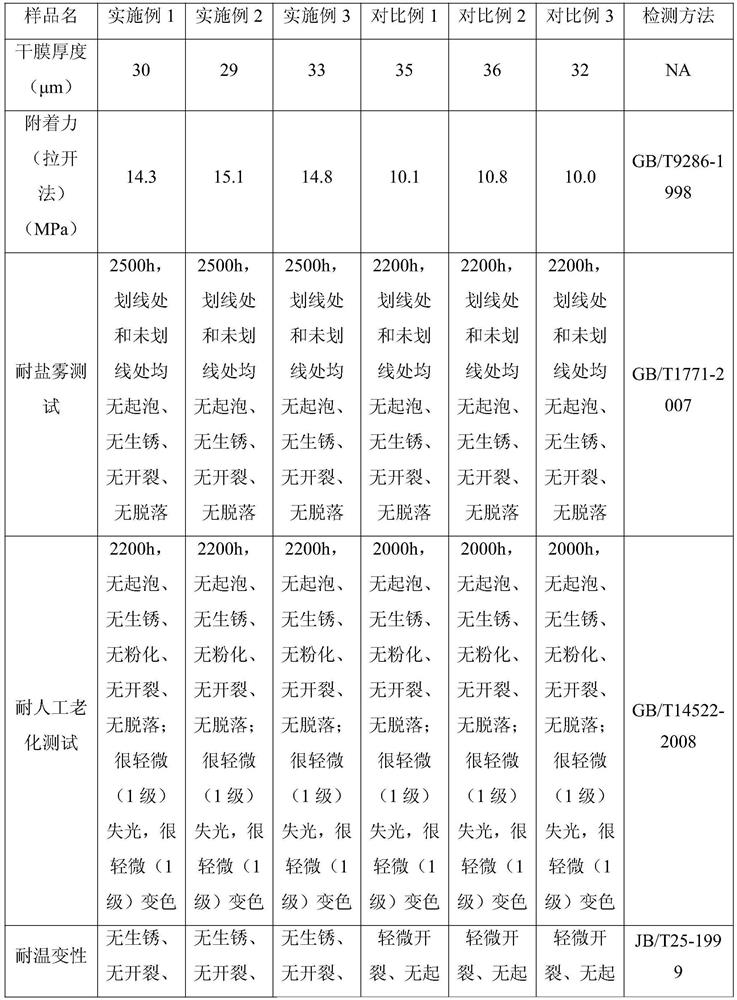

Embodiment 1

[0032] 1) Take 56 parts of hyperbranched polyurethane resin in a beaker, add 2 parts of film-forming aid propylene glycol ethyl ether successively under stirring; 0.5 parts of catalyst BA-120; 8 parts of cross-linking agent hydroxyethyl methacrylate; n-butyl ester 30 parts, high-speed dispersion for 30 minutes, stirring speed 1000rpm;

[0033] 2) 1 part of biological protein (chitosan) and 0.5 part of nano-palladium (particle size: 10 nm) were sequentially added to the solution obtained in 1), and dispersed at high speed for 10 minutes;

[0034] 3) Coat the sample obtained in 2) on the surface of a dry and rust-free 304 stainless steel plate by brushing, with a coating thickness of 50um, and dry it naturally.

Embodiment 2

[0036] 1) Take 56 parts of hyperbranched polyurethane resin in a beaker, add 1.5 parts of film-forming aid propylene glycol ethyl ether successively under stirring; 120.5 parts of catalyst BA-1; 8.5 parts of crosslinking agent hydroxyethyl methacrylate; n-butyl ester 30 parts, high-speed dispersion for 30 minutes, stirring speed 1000rpm;

[0037] 2) 1 part of biological protein (mussel adhesion protein) and 0.5 part of nano-gold (particle size 50nm) were added successively in 1) the obtained solution, and dispersed at high speed for 10 minutes;

[0038] 3) Coat the sample obtained in 2) on the surface of a dry and rust-free 304 stainless steel plate by brushing, with a coating thickness of 50um, and dry it naturally.

Embodiment 3

[0040] 1) Take 56 parts of hyperbranched polyurethane resin in a beaker, add 1.5 parts of film-forming aid propylene glycol ethyl ether successively under stirring; 120.5 parts of catalyst BA-1; 8.5 parts of crosslinking agent hydroxyethyl methacrylate; n-butyl ester 30 parts, high-speed dispersion for 30 minutes, stirring speed 1000rpm;

[0041] 2) 1 part of biological protein (mussel adhesion protein) and 0.5 part of nano-silver (particle size 80nm) were added successively in 1) the obtained solution, and dispersed at high speed for 10 minutes;

[0042] 3) Coat the sample obtained in 2) on the surface of a dry and rust-free 304 stainless steel plate by brushing, with a coating thickness of 50um, and dry it naturally.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com