Automatic bacterial colony selecting instrument and selecting method

A colony and automatic technology, applied in the direction of sterilization methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of limited cleaning time, incomplete cleaning, and reduced reliability and scientificity of experimental results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

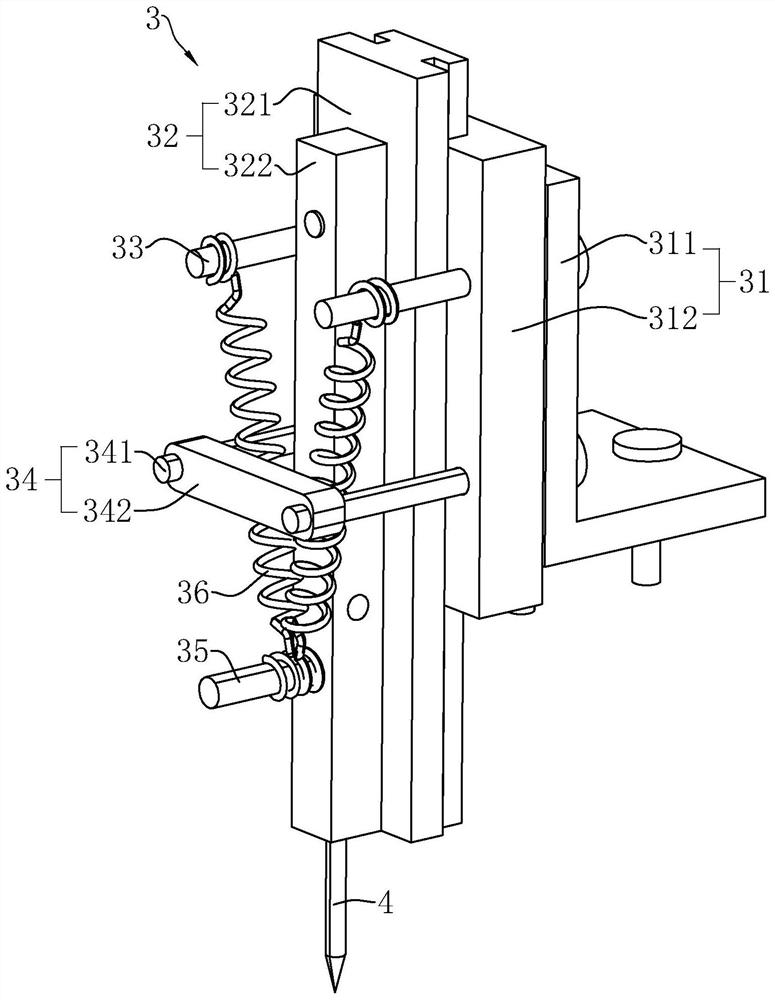

[0077] combine Image 6 and Figure 7 , an automatic colony sorting instrument, the difference from Embodiment 1 is that the cleaning mechanism includes a bracket 741, the top of the bracket 741 is provided with a baffle 742, and the baffle 742 is provided with two radial intervals along the rotating disk 2, two A cleaning channel for the pick pin 4 to pass is formed between the opposite side walls of the baffle plate 742 . The baffle plate 742 is slidably connected to the bracket 741 along the radial direction of the rotating disk 2. The bracket 741 is provided with an oblong hole, and a locking bolt is threaded through the oblong hole from bottom to top, and the locking bolt is threadedly connected to the baffle plate 742. At the bottom, locking bolts are used to lock the baffle 742 in a fixed position. Second brushes 743 are respectively fixed on the two side walls of the cleaning channel, the bristles of the second brushes 743 are arranged horizontally, and two groups of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com