Outer ring type beam column rigid connection joint

A technology of rigid connection and connection of nodes, applied in columns, joists, girders, etc., can solve the problems of large column cross-section size, affecting building use requirements, etc., to ensure quality, improve connection strength and aesthetics, reduce construction costs and effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

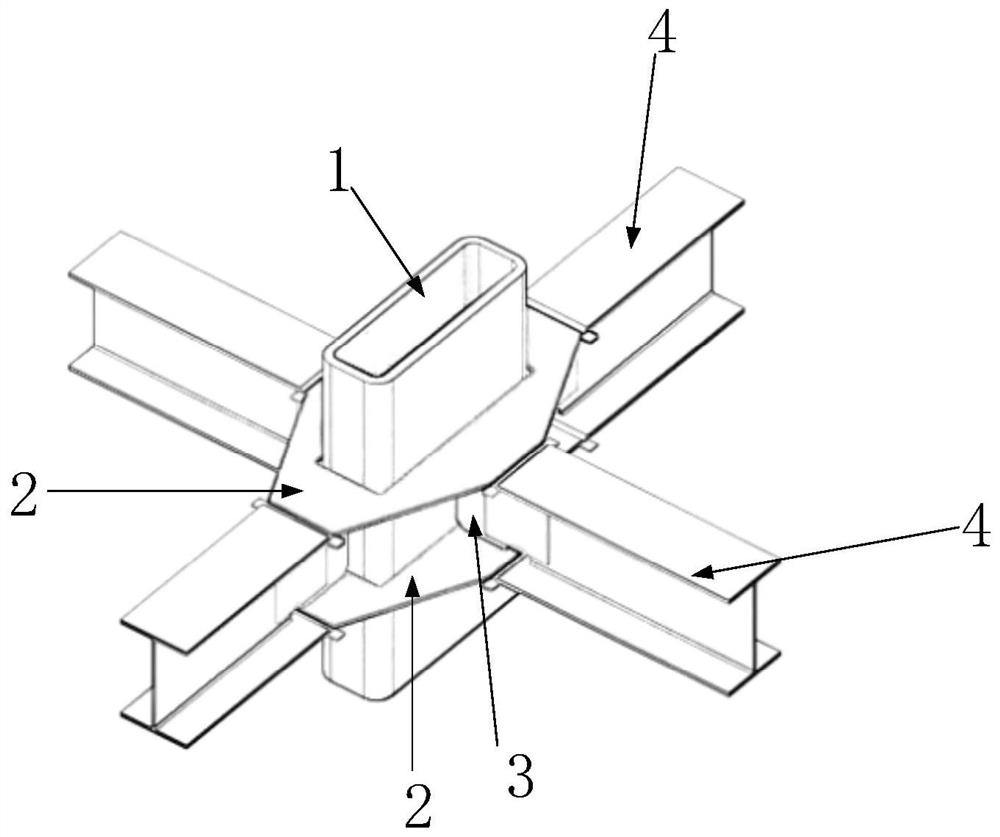

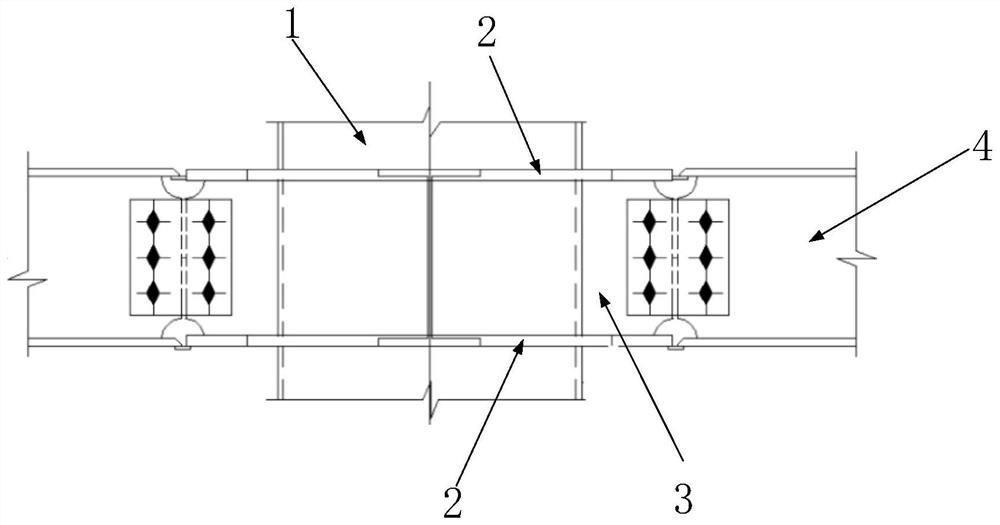

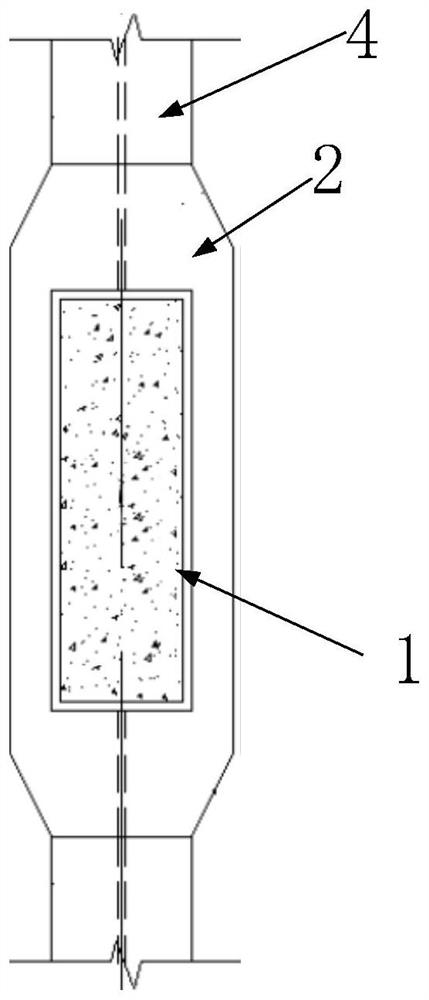

[0027] An outer ring beam-column rigid connection node, used for beam-column joints of building partition walls, such as Figure 1~4 As shown, the connecting nodes include a rectangular steel tube concrete column 1, a plurality of H-shaped steel beams 4, two outer ring horizontal stiffeners 2 and four webs 3, and the middle part of the outer ring horizontal stiffener 2 is provided with a rectangular steel pipe The cross-sectional shape of the concrete column 1 matches the perforation 5, the outer ring horizontal stiffening plate 2 is set on the peripheral side of the rectangular steel tube concrete column 1, the webs 3 are respectively set on the four sides of the rectangular steel tube concrete column 1, and the sides of the web 3 The side is fixedly connected with the rectangular steel tube concrete column 1, the top surface of the web 3 is fixedly connected with the bottom surface of the upper outer ring horizontal stiffener 2, and the bottom surface of the web 3 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com