LSP board embedded light steel keel heat preservation structure wall and construction method thereof

A light steel keel and wall technology, applied in thermal insulation, building thermal insulation materials, walls, etc., can solve problems such as poor structural strength and wall fractures, and achieve the goals of increasing strength, improving sound insulation and heat preservation, and reducing wall fractures effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

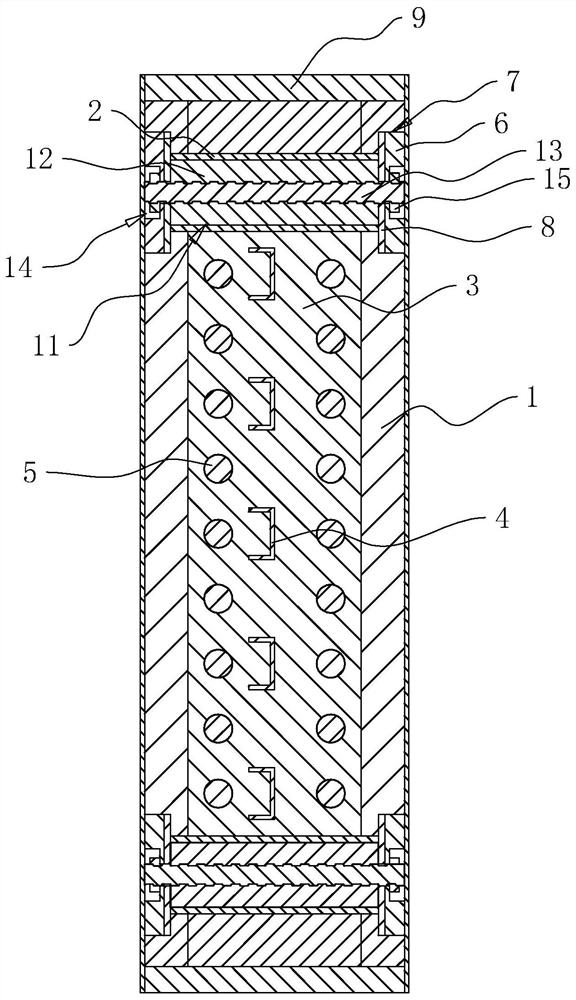

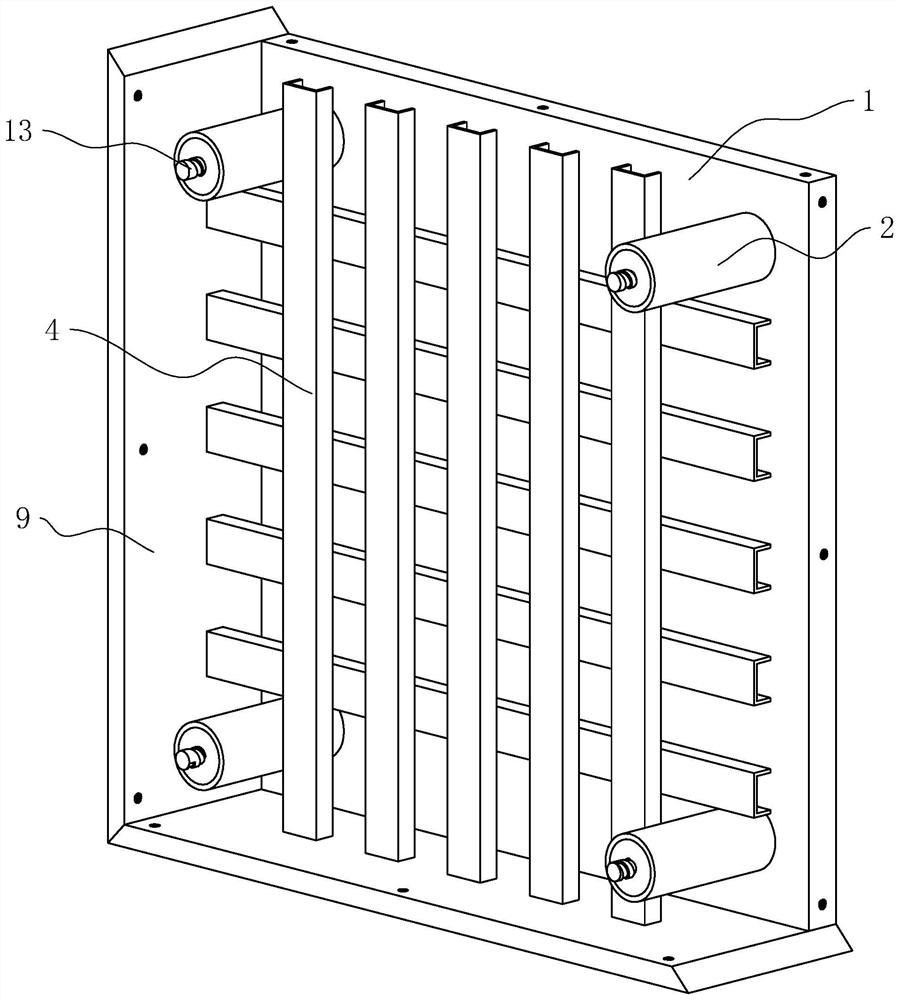

[0039] The following is attached Figure 1-3 The application is described in further detail.

[0040] The embodiment of the present application discloses a light steel keel insulation structure wall embedded with LSP boards.

[0041] refer to figure 1 and 2 , a light steel keel insulation structure wall embedded in an LSP board includes two rock wool insulation boards 1 arranged parallel to each other, and a plurality of connecting columns 2 are connected between the two rock wool insulation boards 1 , and in this embodiment, there are Four, two rock wool insulation boards 1 are also provided with a microporous concrete layer 3, and a light steel dragon frame 4 is embedded in the microporous concrete layer 3.

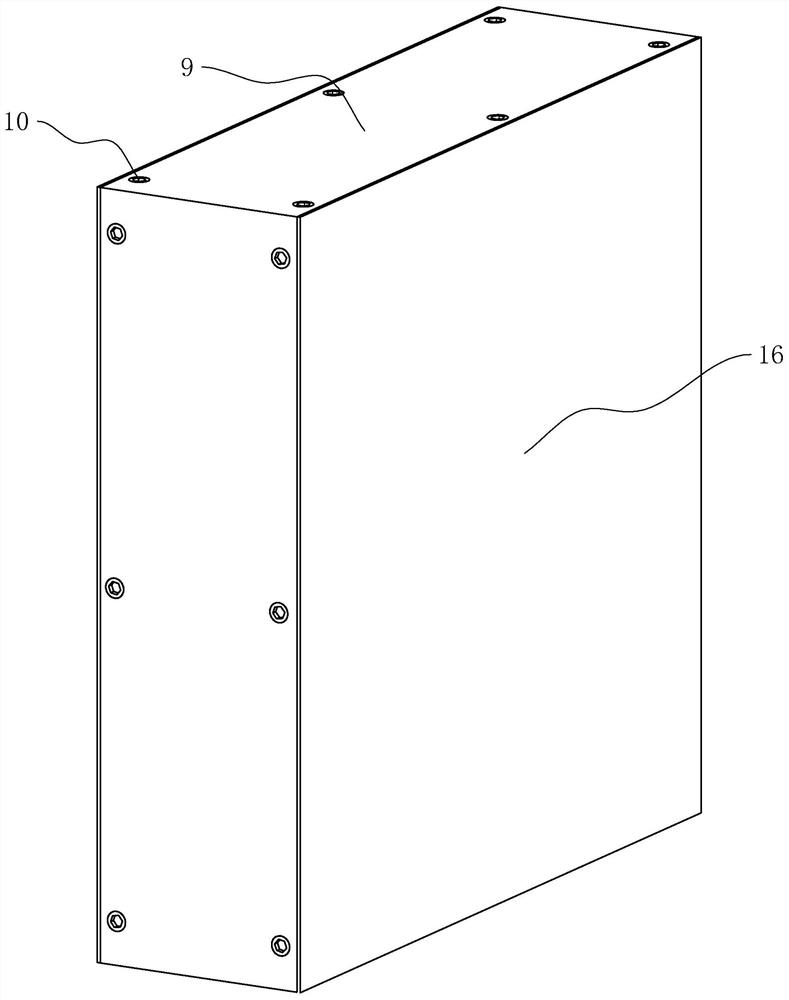

[0042] refer to figure 1 and 3 , two rock wool insulation boards 1 are connected with a positioning board 9, four positioning boards 9 are arranged, the four positioning boards 9 are arranged around the rock wool insulation board 1, and two columns of bolts 10 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com