Throttling element regulation and control method for coal pulverizing system to realize uniform distribution of pulverized coal

A throttling element and pulverizing system technology, applied in the direction of instruments, electrical digital data processing, computer-aided design, etc., can solve problems affecting the safe operation of boilers, unfavorable coal consumption and pollutant discharge, and deviation of coal powder flow distribution, etc., to achieve Reduce unsafe factors and economic losses, improve safe and stable operation, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0035] Example.

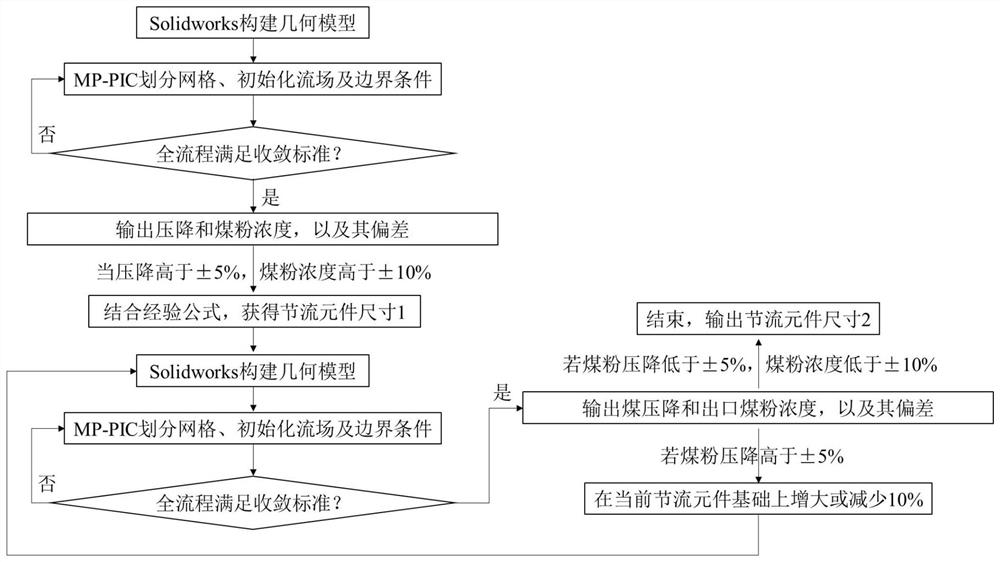

[0036] In this embodiment, a throttling element control method for a pulverizing system to realize uniform distribution of coal powder includes the following steps:

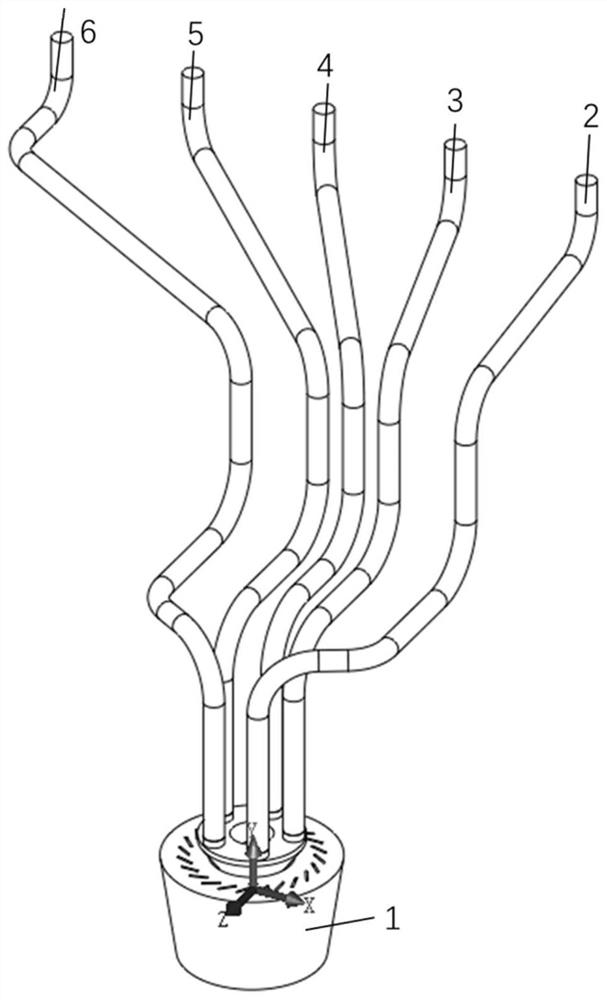

[0037] 1) Use Solidworks 3D software to conduct a 1:1 geometric modeling of the coal pulverizer of the boiler pulverizing system and its parallel pulverized feeding pipeline device, as shown in figure 2 shown.

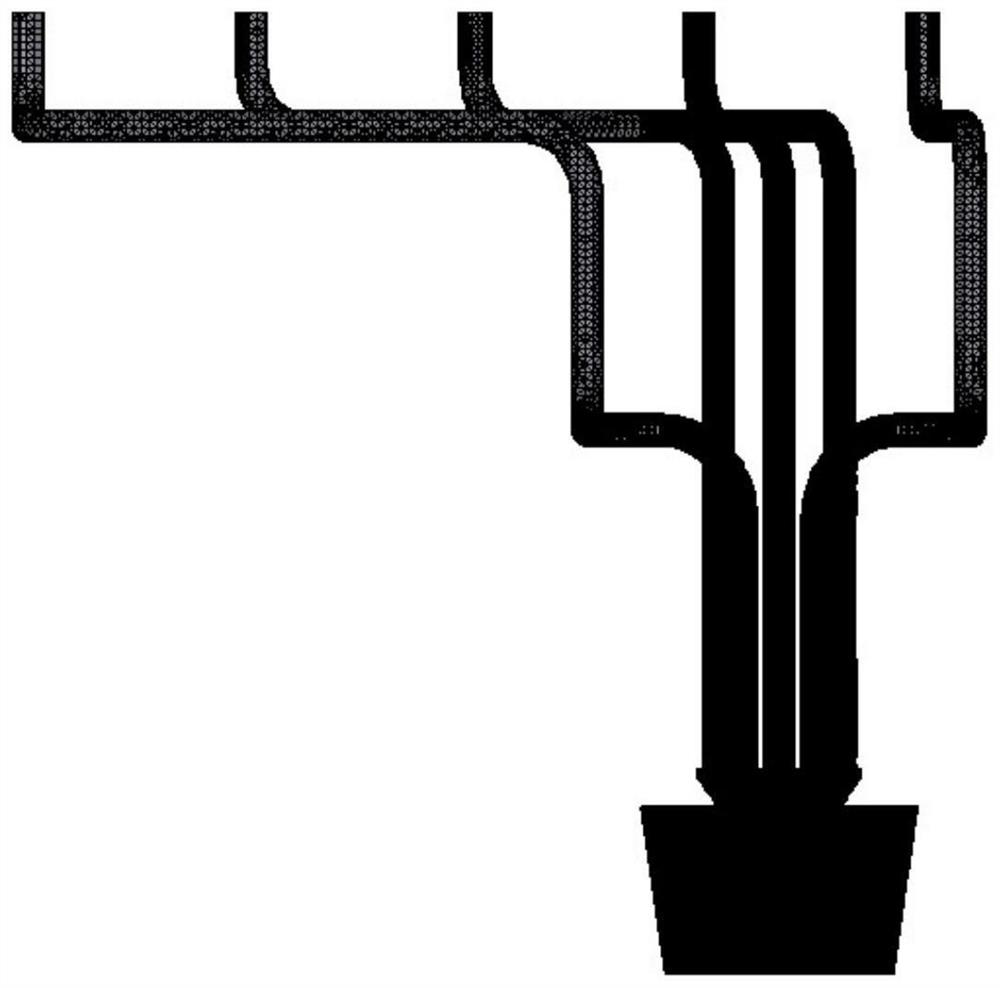

[0038] 2) Use the MP-PIC method to mesh the constructed geometric model of the boiler pulverizing system, as shown in image 3 shown. Set the initial flow field and boundary conditions according to the operating conditions of the pulverizing system and related physical properties (particle size, particle density, fluid pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com