Occupational health automatic classification and level-to-level management system, sensing module and process

A hierarchical management and automatic classification technology, applied in data processing applications, character and pattern recognition, computer-aided medical procedures, etc., can solve problems that cannot be predicted and analyzed in time, affect the enthusiasm of employers to fill in reports, and cannot control the authenticity. , to achieve the effect of compact structure, reasonable design and saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1, such as Figure 1-5 As shown, the occupational health automatic classification and grading management system of this embodiment includes an application layer, a network layer and a perception layer;

[0049] The application layer includes the client terminal of the employer, the working computer of the medical examination center and the server of the supervision and management department;

[0050] The perception layer is a sensor component installed in the employer's workshop 1, which is used to collect work environment information and upload it to the application layer through the network layer;

[0051] A hierarchical management module is built on the server of the client and the supervision and management department, and a technical service center system is also built on the server of the supervision and management department;

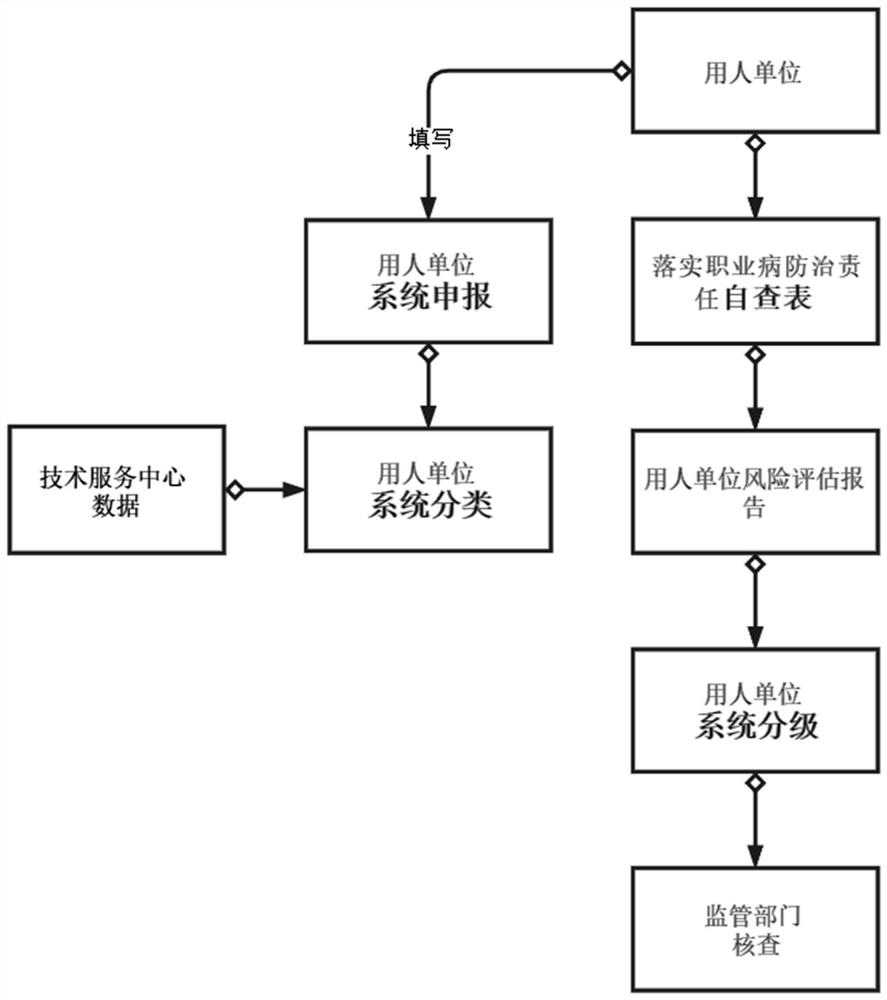

[0052] The hierarchical management module is connected to the technical service center system and the physical examination cente...

Embodiment 2

[0059] Example 2, such as Figure 1-5 , the occupational health automatic classification and grading management process of this embodiment,

[0060] Step 1. First, establish a database of occupational disease hazard factors, including the name of occupational disease hazard factors and their category, nature, and occupational exposure limit; then, establish a national economic industry classification database and unit size large, medium, small, and micro classification standards for employers to query and select;

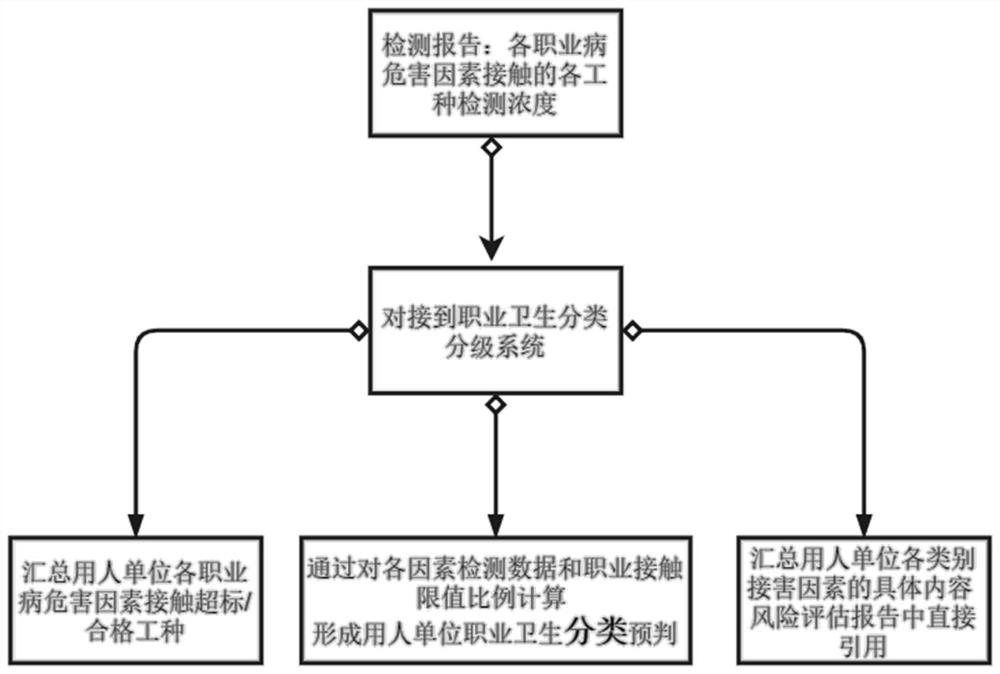

[0061] Step 2. Connect with the technical service center. First, extract the test report. The test report includes the type of work, the name of occupational disease hazard factors, the test concentration, and the judgment result; Judgment result;

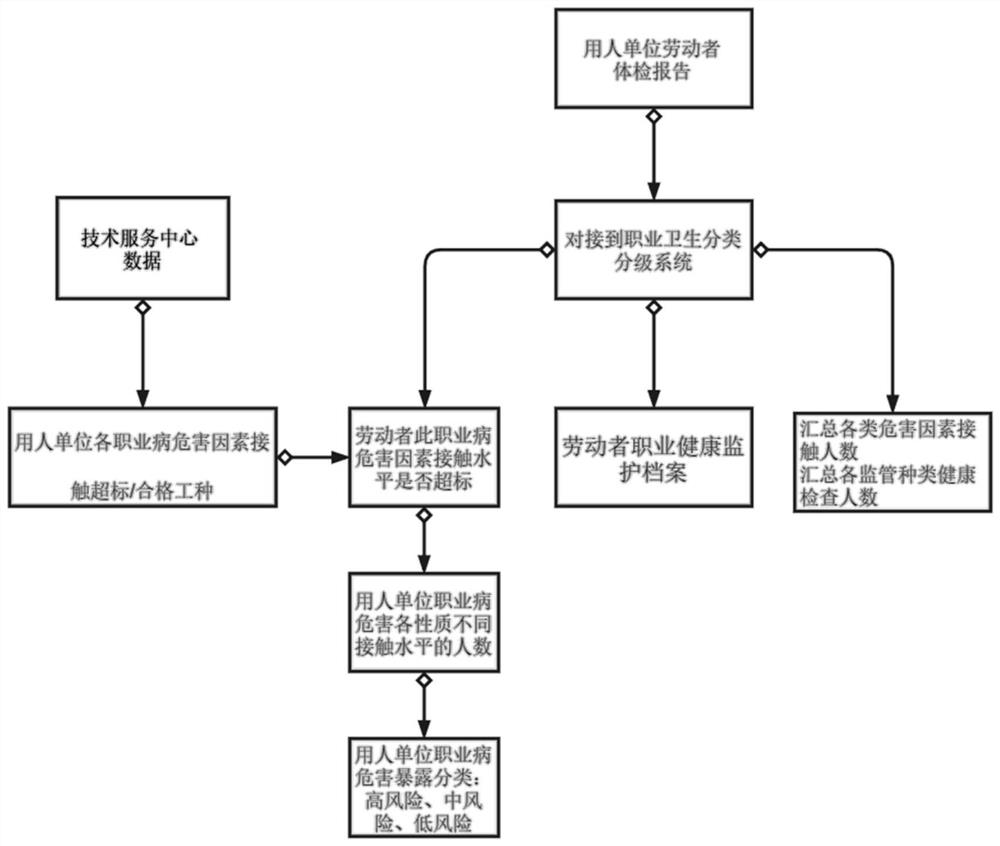

[0062] Step 3, docking with the medical examination center, firstly, extracting the personal information of the laborer, which includes the employer, type of work, and exposure to occupational disease hazard factors. W...

Embodiment 3

[0068] Embodiment 3, the sensor assembly includes the working door camera 2 and the information reading device 3 arranged on the working door of the working workshop 1, to record the identity, time and times of the personnel entering and leaving the working workshop 1;

[0069] A probe monitoring device 4 for collecting occupational hazard factors is set in the workshop 1;

[0070] A probe installation rod 5 is arranged on the top of the workshop 1, a probe rotation slope 6 is arranged at the cantilever end of the probe installation rod 5, and the root of a vertical rotation rod 7 is vertically arranged on the probe rotation slope 6, and the vertical The root of the rotating arm 8 is provided, the first telescopic arm 9 is arranged on the rotating arm 8, the second driving arm 10 is arranged at the end of the first telescopic arm 9, and the central connecting rod is arranged at the end of the second driving arm 10 11. A central guide rod 12 is provided at the end of the centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com