Method and apparatus for producing quick lime using coke dry quenching facility and heat exchanger

A technology of dry fire extinguishing and heat exchangers, which is applied in the direction of coke cooling, heat exchangers, heat exchanger types, etc., and can solve problems such as poor thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

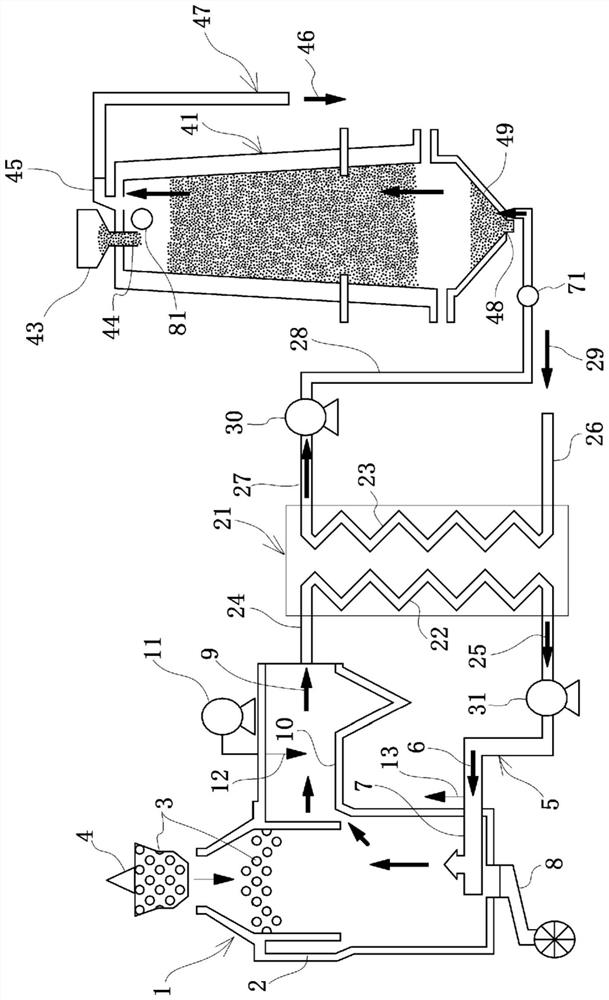

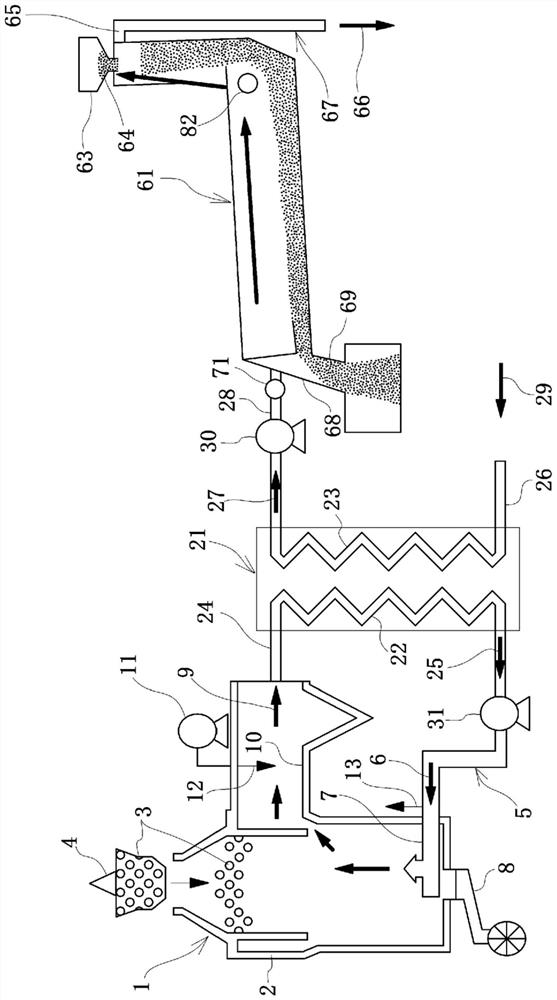

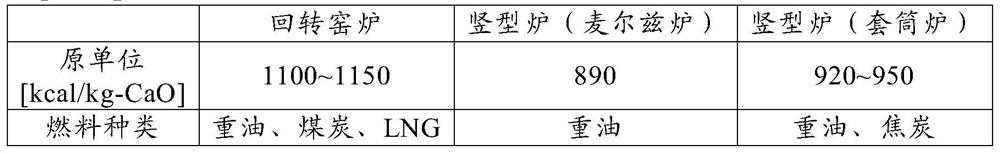

[0049] use figure 1 The manufacturing apparatus of the shown structure, according to the manufacturing method of quicklime using the coke dry fire extinguishing equipment and heat exchanger of the present invention, in the following Invention Example 1, Invention Example 2, Invention Example 3, Invention Example 4 and Comparative Example 1 conditions to produce quicklime. First, the balance of heat energy when limestone is pyrolyzed to produce quicklime is as follows.

[0050] Consider the following: for CaCO in limestone 3 thermal decomposition reaction (CaCO 3 →CaO+CO 2 ) The required heat is 766kcal / kg-CaO, and the sensible heat of circulating gas after coke cooling is 228kcal / Nm 3 (180°C ~ 850°C). per 1Nm 3 The quicklime that can be produced by the circulating gas is 228 / 766 = maximum 0.297kg-CaO / Nm 3 .

[0051]

[0052] According to the manufacture method of quicklime utilizing coke dry fire extinguishing equipment and heat exchanger of the present invention, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com