Interlayer greenhouse-in-greenhouse heat preservation greenhouse

A heat-insulating greenhouse and interlayer technology, which is applied in greenhouse cultivation, horticulture, climate change adaptation, etc., can solve the problems of general heat preservation timeliness, indoor temperature cannot be maintained for too long, and low investment, so as to achieve long heat preservation time and reduce temperature drop Speed, the effect of increasing the internal temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

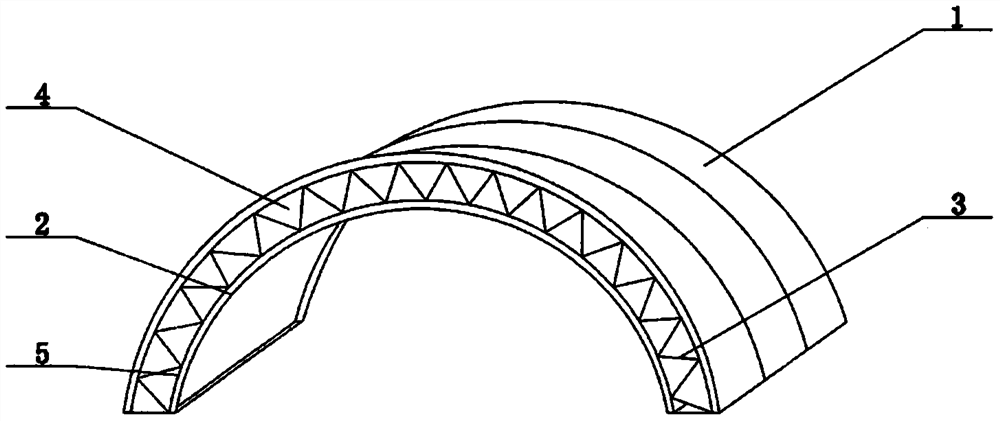

[0017] see figure 1 As shown, the technical solution adopted in this specific embodiment is: it is composed of an outer layer of greenhouse film 1, an inner layer of greenhouse film 2, a greenhouse frame 3, a thermal insulation layer 4, and an installation groove 5, and the installation groove 5 is arranged on the lower layer of the greenhouse frame 3 , the outer greenhouse film 1 is connected to the upper layer of the greenhouse framework 3, the inner greenhouse film 2 is connected to the installation groove 5, and the outer greenhouse film 1 and the inner greenhouse membrane 2 are connected through the greenhouse framework 3 to form an insulating interlayer 4. The outer layer of greenhouse film 1 and the inner layer of greenhouse film 2 are combined to form an insulating interlayer 4, forming an interlayer shed-in-a shed structure, which can increase the internal temperature of the shed and reduce the temperature drop rate.

[0018] Further, the outer greenhouse film 1 is ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com