Micro-rain atomizing pesticide spraying system

A technology of medicine delivery and medicine barrel, which is applied in the device, application, animal husbandry and other directions of capturing or killing insects, can solve the problems of insufficient efficiency, limited flight safety, labor hard work, etc., and achieves good atomization effect and spraying effect. Large area and high spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

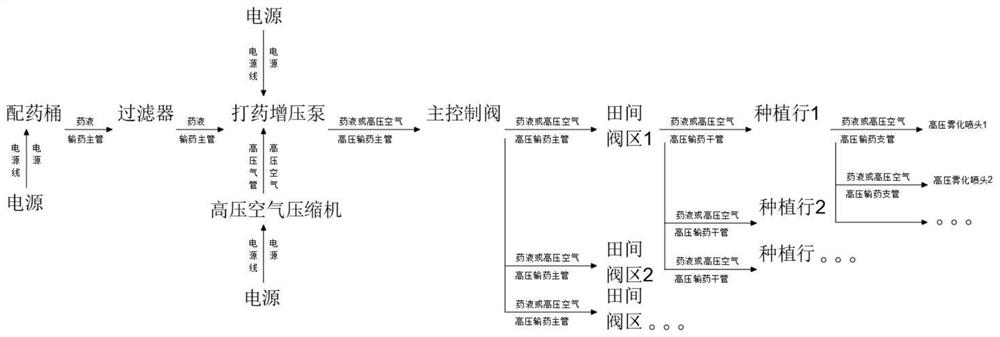

[0022] Please refer to figure 1 in, figure 1 It is a composition diagram of the spraying system of light rain and mist spraying provided by the present invention.

[0023] In the specific implementation process, such as figure 1 Shown, dispensing tank, filter, spraying booster pump, high-pressure air compressor, power supply, main control valve, field valve area and planting row, the dispensing tank is connected to the filter through the drug delivery main pipe, and the filter is connected to the drug delivery main pipe The drug inlet of the spraying booster pump and the air outlet of the high-pressure air compressor are connected to the air inlet of the spraying booster pump through a high-pressure air pipe. The high-pressure drug delivery main pipe is connected to the field valve area, and the field valve area is connected to the planting row throu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap