Sand screening and classifying equipment for buildings

A technology for screening and classification, construction, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of difficult centralized collection, high labor intensity, easy mixing, etc., to achieve easy installation and disassembly, reduce labor intensity, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

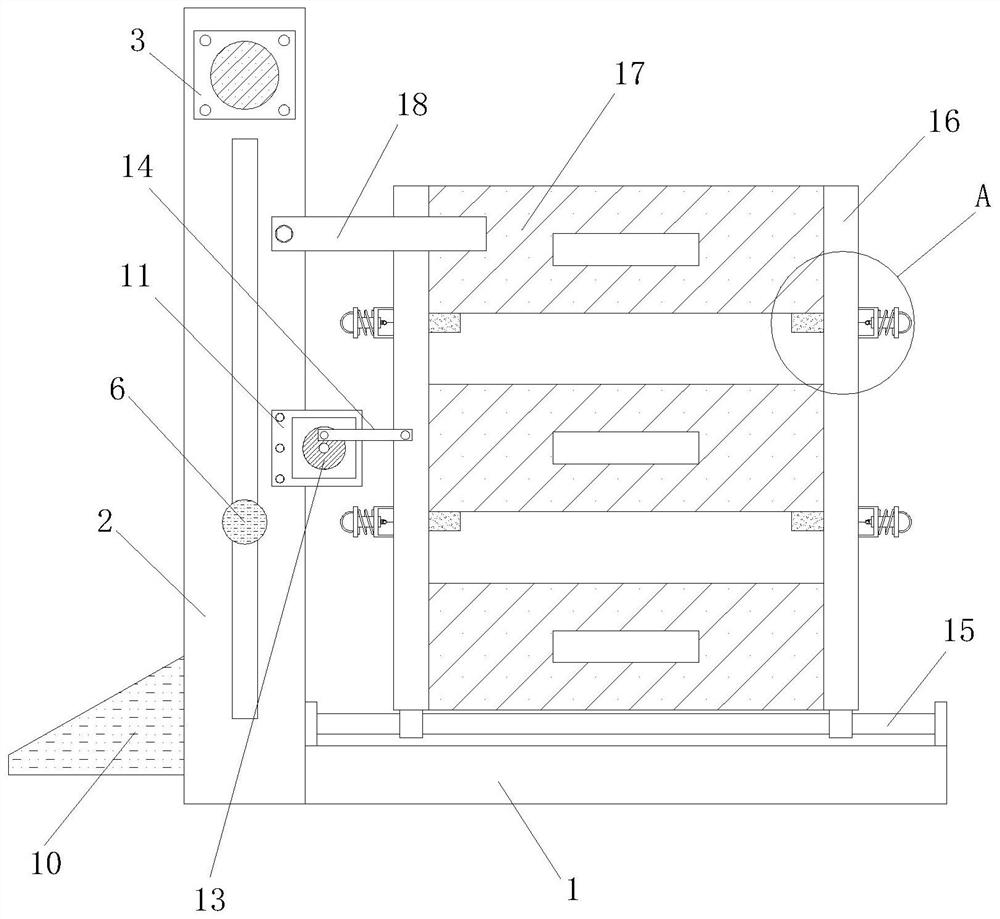

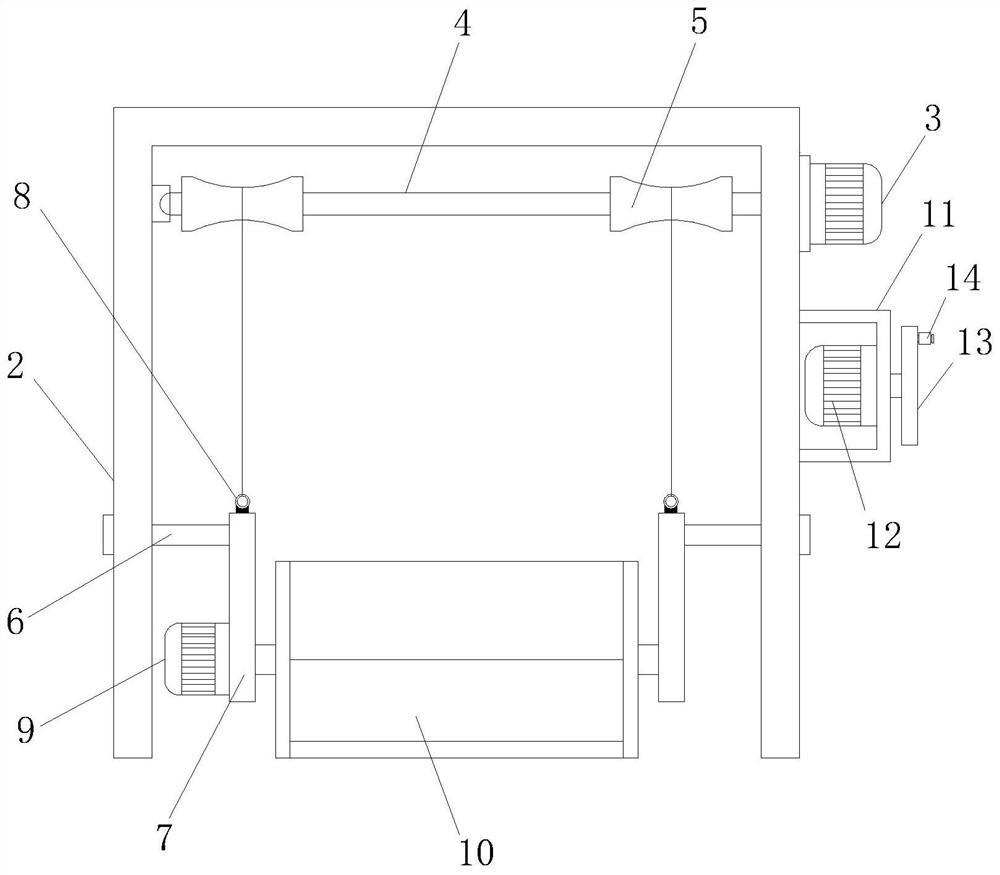

[0038] Embodiment one, such as figure 1 As shown, the front and back of the base 1 are provided with rectangular slots, and the two sets of limit rods 6 extend through the corresponding rectangular slots to the outside, and end plates are installed at the end of the extension section, and the hanging plate 7 passes through the limit The position bar 6 and the end plate are connected with the supporting frame 2, and through the setting of this structure, the stability during the lifting process of the hanging plate 7 can be maintained during use.

Embodiment 2

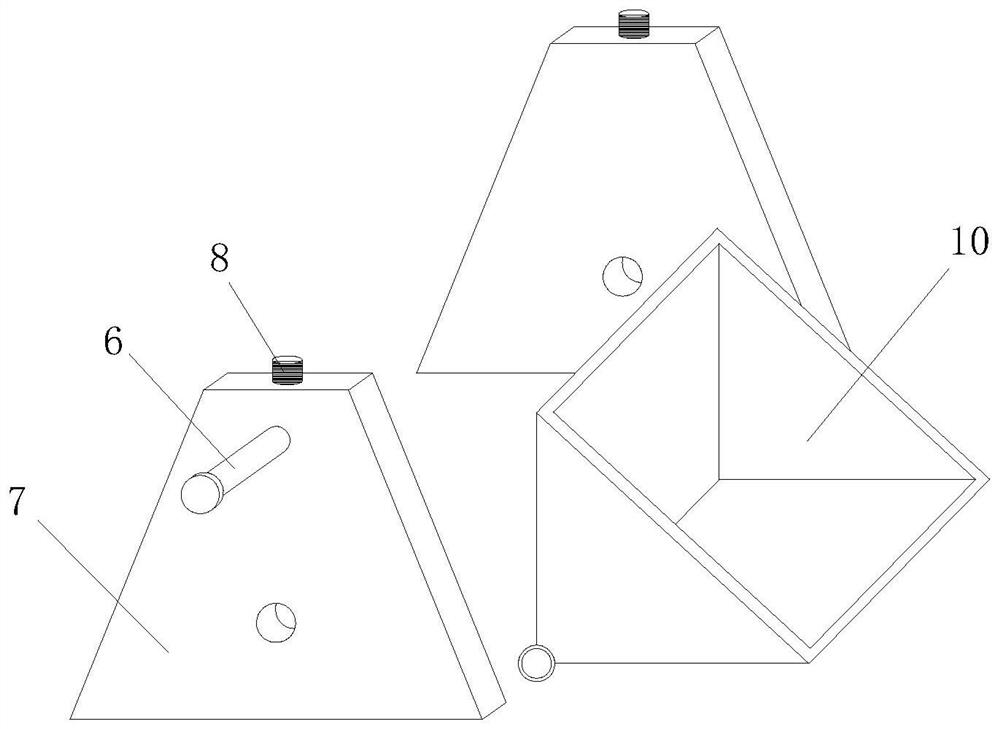

[0039] Embodiment two, such as Figure 4 , Figure 7 with Figure 8 As mentioned, the other end of the spring 21 is equipped with a locking lever 22, and one end of the locking lever 22 is threaded with a second suspension ring 23, and the inner rotation of the housing 16 is equipped with a stopper 24, and a third suspension ring 25 is installed on the surface of the stopper 24. The outer surface of the housing 16 is provided with a mounting groove, and the inside of the mounting groove is rotated to install a power rod, the surface of the power rod is equipped with a guide wheel 26, and the opposite end of the second suspension ring 23 and the third suspension ring 25 is equipped with a stay rope 27, By adopting the stopper 24 to separate the three groups of screens 17, it is possible to avoid overlapping and friction between the screens 17 to affect the screening effect, and it is also convenient to install and disassemble the screens 17.

[0040] Working principle: when i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com