Equipment for notebook computer polishing and grinding

A technology of polishing and grinding, which is applied in the direction of grinding/polishing equipment, machine tools for surface polishing, metal processing equipment, etc. It can solve the problems of restricting the development of the industry, low efficiency, and low polishing efficiency, so as to reduce the cost of consumables and reduce Workers' labor volume and work continuity are good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

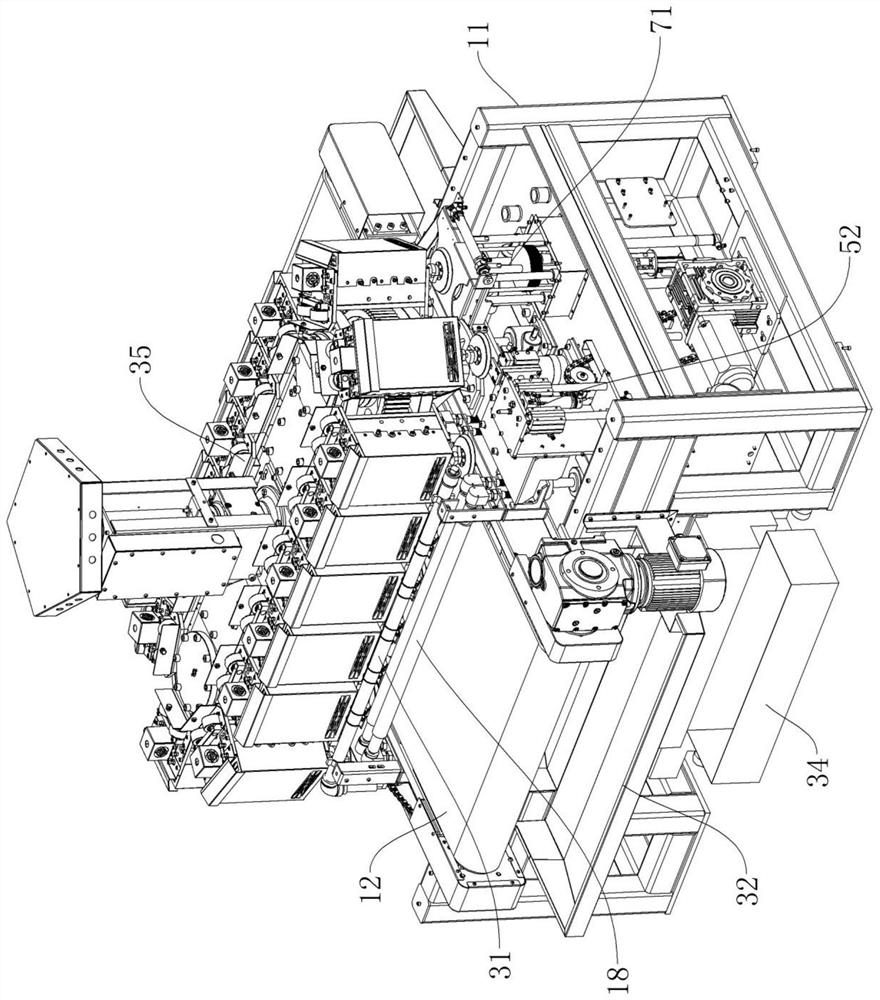

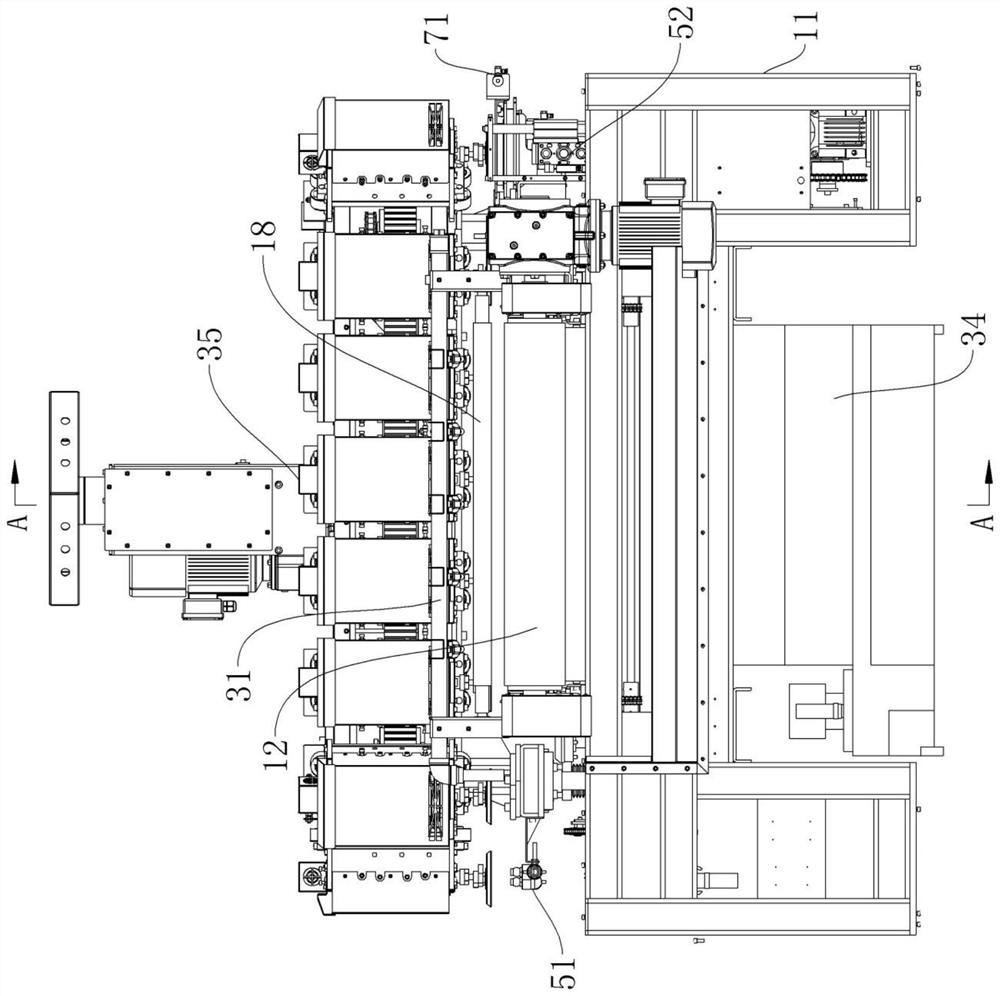

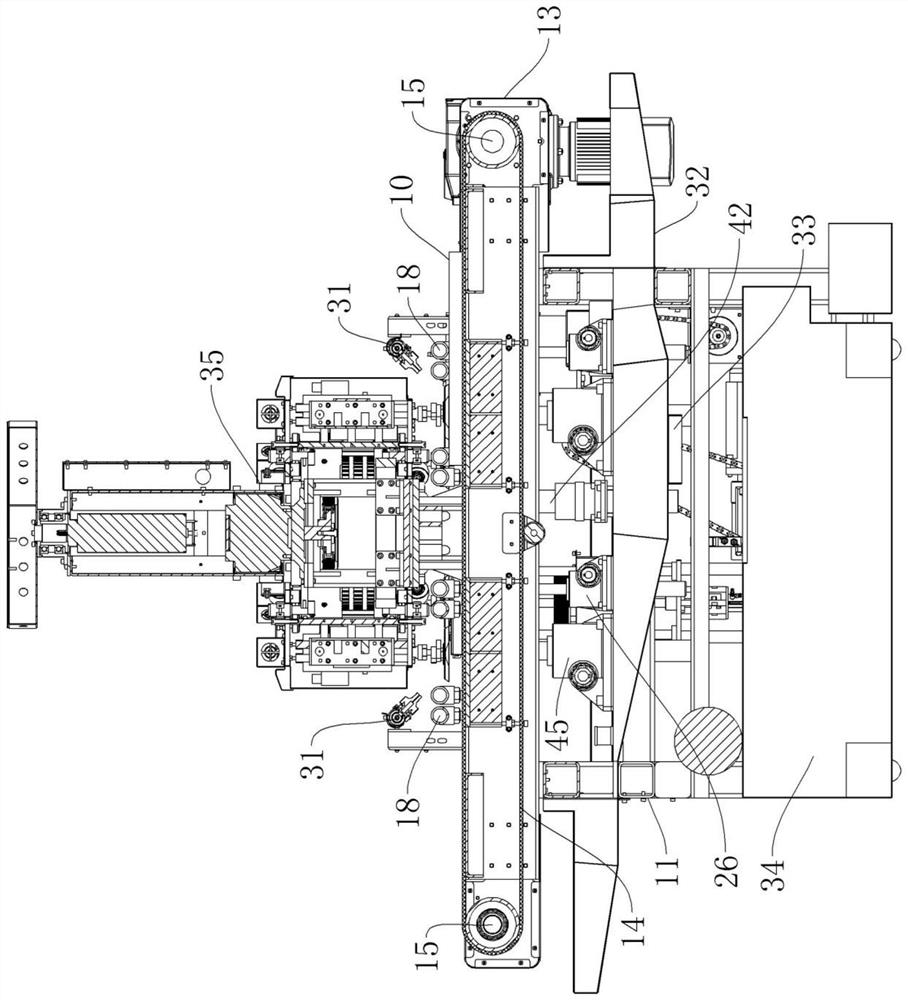

[0041] refer to Figure 1-Figure 19 Shown, the present invention is an embodiment of a kind of equipment that is used for notebook polishing;

[0042] refer to Figure 1-Figure 3 As shown, a kind of equipment that is used for notebook polishing, comprises: conveying mechanism 12, and described conveying mechanism 12 is installed on support frame 11, and described conveying mechanism 12 comprises the conveyor belt 14 of horizontal rotation, a plurality of horizontally arranged in parallel Pressing roller 18, described pressing roller 18 is arranged on the top of conveyer belt 14 and both rotate and cooperate to clamp and transport workpiece; Since notebook case 10 adopts the polis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com