Solution compound distributor for PVC film processing

A dispenser and melt technology, which is applied in the field of melt composite dispensers, can solve the problems of lower product quality and uneven material compounding, and achieve the effects of improving safety, improving aesthetics, and avoiding wrong installation angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

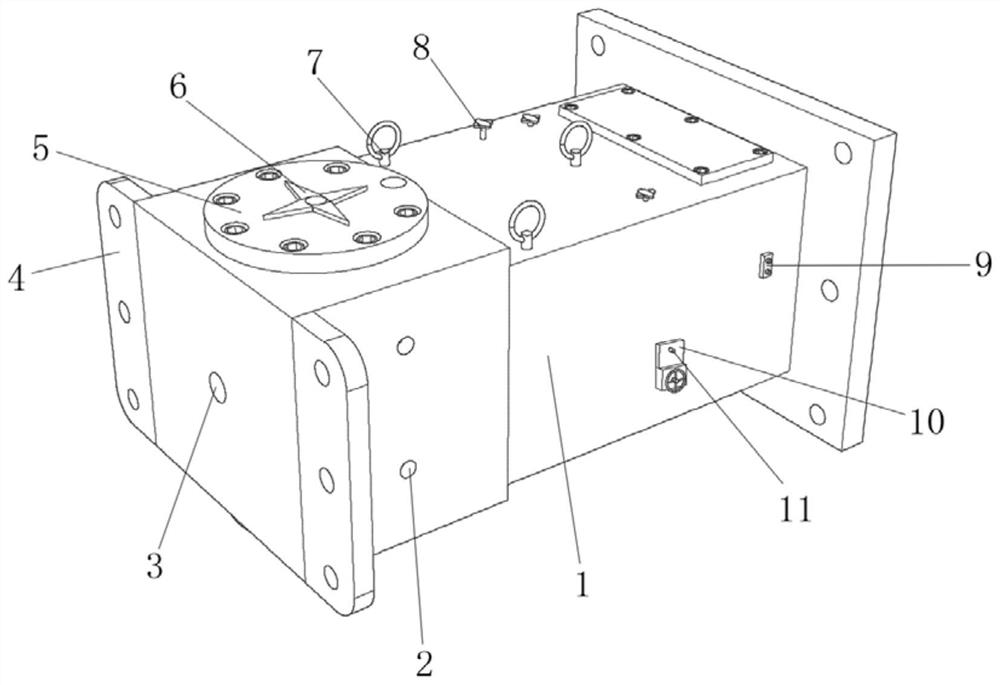

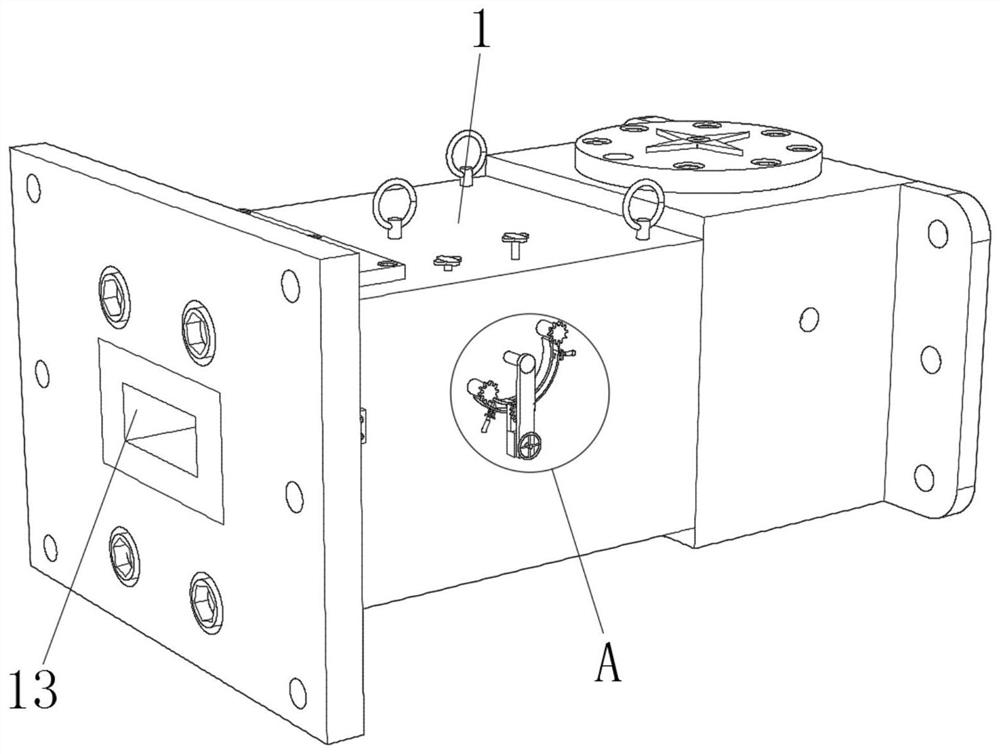

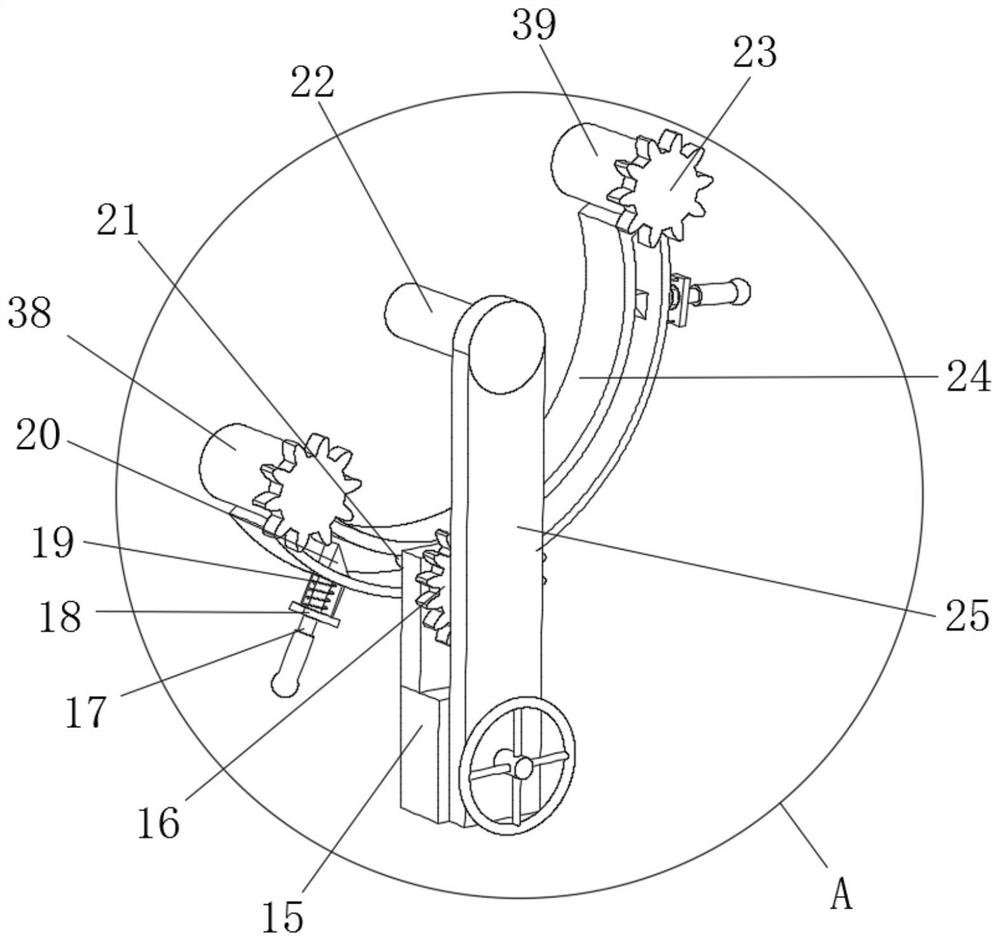

[0031] refer to Figure 1-Figure 6 , a melt composite distributor for PVC film processing, comprising a body 1, a shunt core 27 is plugged into the body 1, the two ends of the shunt core 27 are fixed with fixed discs 5 by bolts, and the fixed discs 5 are respectively connected to the body The top and the bottom of 1 are fixed, and the splitter core 27 has the effect of diversion, and can introduce different raw materials into the body 1, and the body 1 and the peripheral outer wall of the splitter core 27 are provided with a main channel 28 and three splitter channels 40, the body One side of the body 1 is provided with a main feed port 3, and both sides of the machine body 1 are provided with a sub-feed port 2, and the sub-feed port 2 communicates with the sub-flow channel 40, and the main feed port 3 communicates with the main channel 28 , one side of the body 1 is plugged with a composite board 36, the top and bottom of the composite board 36 are fixed with a fixed plate 30...

Embodiment 2

[0033] refer to Figure 1-Figure 6, the present invention provides a new technical solution: a melt composite dispenser for PVC film processing, including a body 1, the upper surface of the body 1 is provided with a plurality of threaded holes, and the threaded holes are internally threaded with lifting lugs 7, Both sides of the body 1 are integrally formed with side ears 4, and one side of the side ears 4 is provided with a plurality of fixing holes, through which the fixing of the device is facilitated. The fixed disc 5 is fixed by bolts, and the fixed discs 5 are respectively fixed to the top and the bottom of the body 1, and the bottom of one of the fixed discs 5 is fixed with a limit block 26 by bolts, and the limit block 26 is inserted into the body 1, The upper surface of one of the fixed disks 5 is welded with an indicator needle 6, the limit block 26 and the indicator needle 6 can improve the installation accuracy of the fixed disk 5, and the shunt core 27 has the fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com