Powerful shaping process for disposable paper container

A paper container, one-time technology, applied in the field of paper containers, can solve the problems of poor forming stability of paper containers, and achieve the effects of good shaping effect, good forming stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A strong shaping process for a disposable paper container. In this embodiment, the paper container is a round paper plate, which includes the following steps:

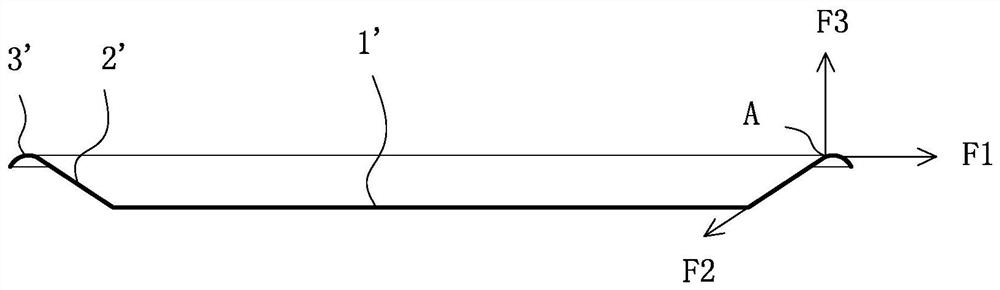

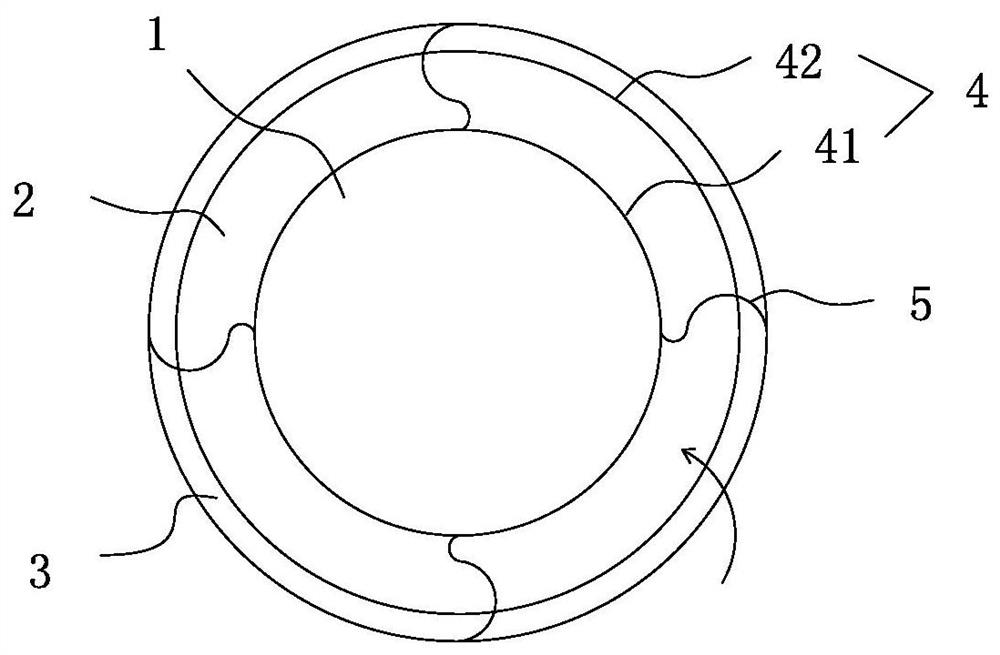

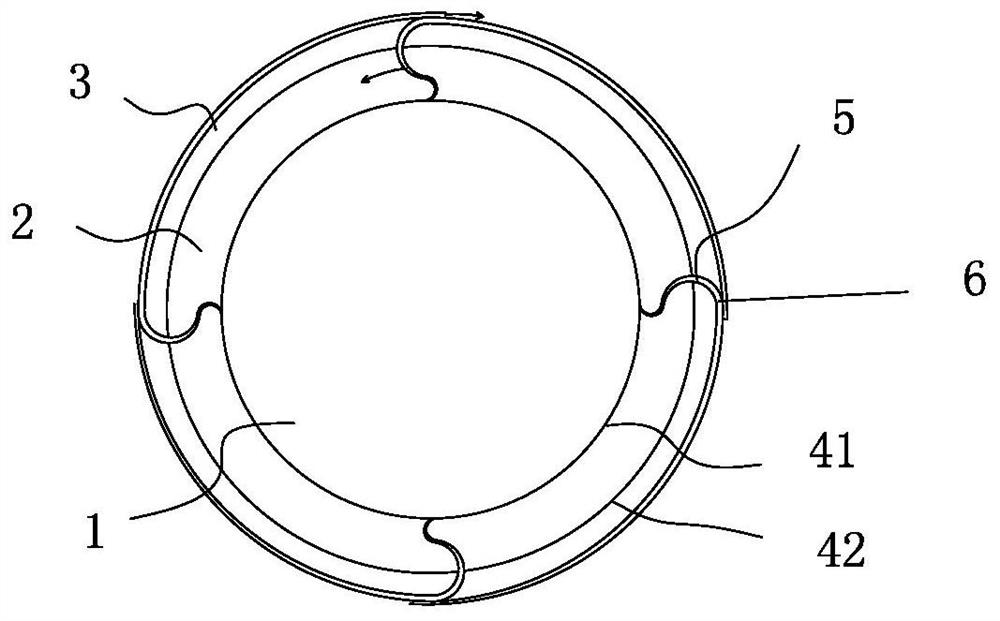

[0046] 1) Reference Figure 2a As shown, cut the cardboard and press out the creasing line 4, so that the outline of the bottom 1, slope surface 2 and end edge 3 of the round paper plate can be formed. When cutting the cardboard, first cut out the excess part Form a circular structure in a flattened state of the round paper tray, and cut out four cutting lines 5 along its circumference towards the center point, and the four cutting lines 5 are evenly distributed on the slope surface 2 and the end edge 3 of the round paper tray, Four cutting lines 5 are set so that the structure of the shaped circular paper plate is stable, and the forming effect of the slope surface 2 is good, and the forming is simple. The indentation line 4 includes a first indentation line 41 between the bottom 1 and the slope surface 2 and ...

Embodiment 2

[0050] A strong shaping process for a disposable paper container. In this embodiment, the paper container is a square paper tray, which includes the following steps:

[0051] 1) Reference Figure 3a As shown, cut the cardboard and press out the creasing line 4, so that the outline of the bottom 1, slope surface 2 and end edge 3 of the square paper plate can be formed. When cutting the cardboard, first cut out the excess part Form a square structure in the flattened state of the square paper tray, and cut out four cutting lines 5 along the diagonal direction of the square structure, and the four cutting lines 5 are evenly distributed on the slope surface 2 and the end edge 3 of the square paper tray. The cutting line 5 has an oblique special-shaped structure, and four cutting lines 5 are set to make the shaped square paper plate structure stable, and the forming effect of the slope surface 2 is good, and the forming is simple. The creasing line 4 includes the bottom 1 and the s...

Embodiment 3

[0055] A strong shaping process for a disposable paper container. In this embodiment, the paper container is an oval paper tray, which includes the following steps:

[0056] 1) Reference Figure 4a As shown, the cardboard is cut and the creasing line 4 is pressed out, so that the slope surface 2 and the outline of the end edge 3 of the oval paper plate can be formed. When cutting the cardboard, the excess part is first cut out to form an ellipse The elliptical structure in the flattened state of the oval paper tray, and four cutting lines 5 are cut along its periphery towards the center point, and the four cutting lines 5 are evenly distributed on the slope surface 2 and the end edge 3 of the oval paper tray, Setting four cutting lines 5 makes the structure of the shaped oval paper tray more stable, and the forming effect of the slope surface 2 is good, and the forming is simple, and the indentation line 4 includes the first indentation line 41 between the bottom 1 and the slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com