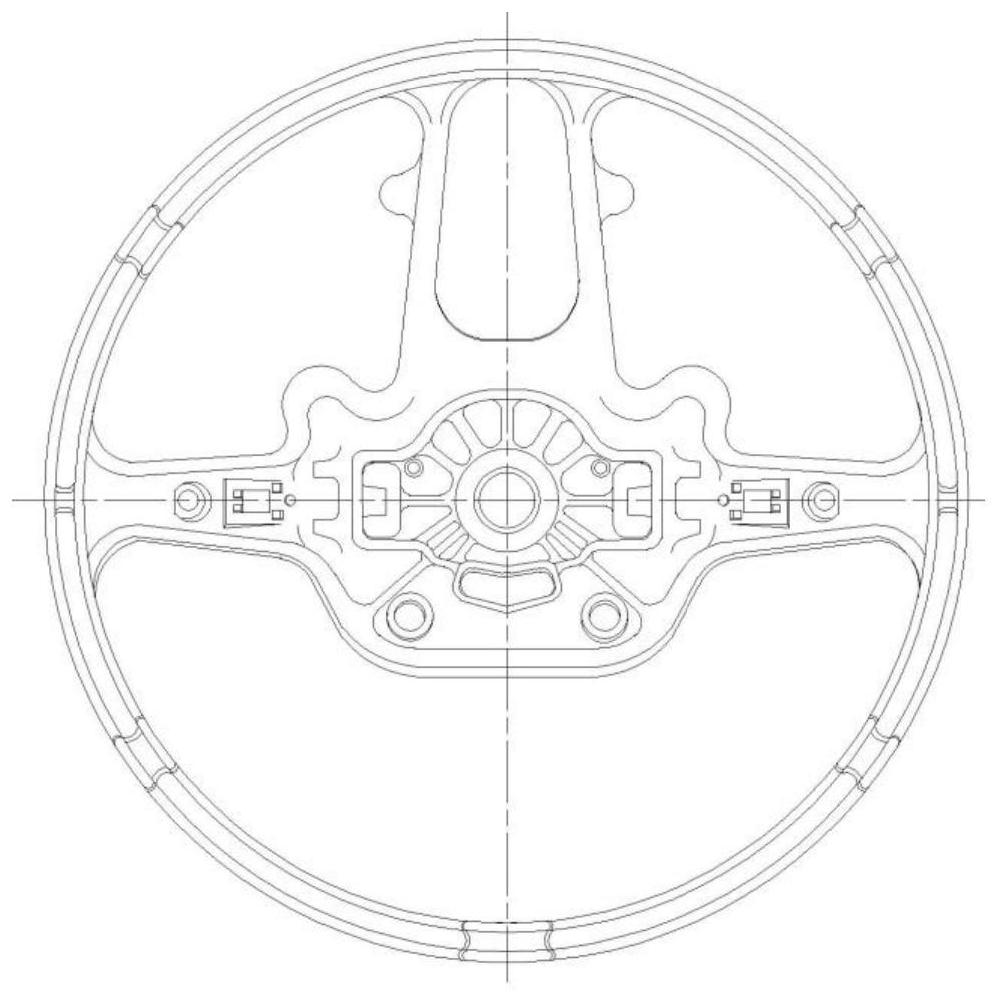

Embedded cold-bending locking structure and method for magnesium alloy steering wheel framework reinforcing steel bars

A technology of locking structure and steering wheel, which is applied in the direction of steering control and handwheel installed on the car, can solve the problem of fracture of the two wings and ears of the spokes of the steering wheel skeleton, and achieve excellent experimental results, short production cycle and high locking force Stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0061] 1. Improvement of die casting mold:

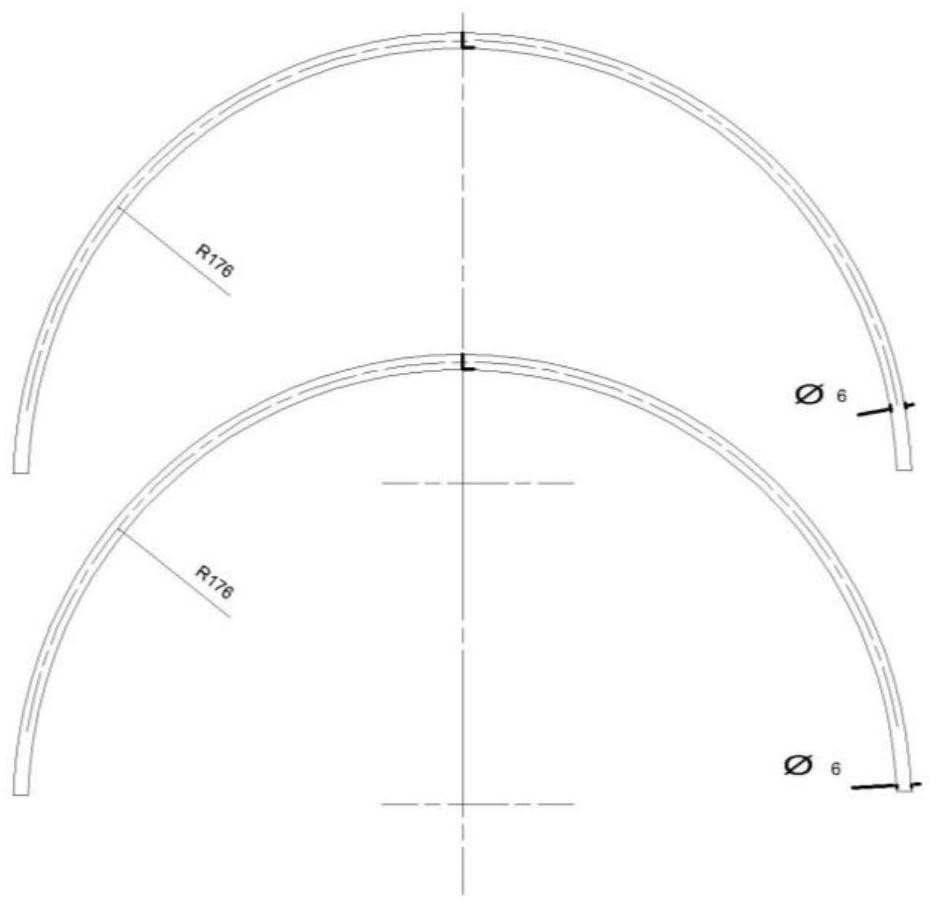

[0062] Because the magnesium alloy steering wheel skeleton has a shrinkage of 8‰, by modifying the die-casting mold, the assembly gap of the steel bar embedded in the magnesium alloy steering wheel can be obtained at an assembly size of 0.04mm, which is the optimal assembly gap.

[0063] 2. Improvement of pressure jaw:

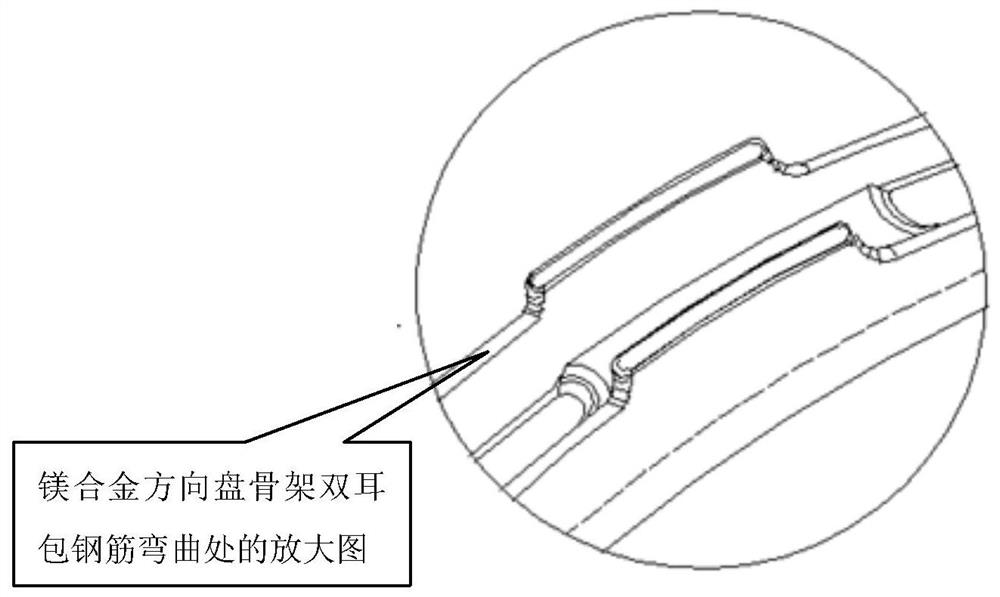

[0064] refer to Figure 7 According to the final compression curvature of the two lugs of the spokes, a dotted line is taken, and a steel sample is made by hand. When repairing, the pressure claws are removed, and the surface of the pressure claws is repaired with a pneumatic tool and the coloring embossing method. The 90° flat surface inside the claw can be changed to a curved surface tangent to r3 and r10 with a surface roughness of Ra0.8. The purpose is to obtain the minimum sliding resistance and good fluidity of the ears when they are bent.

[0065] The assembly gap between the improved magnesium alloy steer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com