Filling equipment capable of controlling discharging amount of chemical raw material medicine

A technology for chemical raw materials and filling equipment, applied in packaging, packaging machines, solid materials, etc., can solve problems such as inability to effectively achieve quantitative packaging, affecting output and personnel health, inability to timely and automatic bagging, etc., to prevent dust. , save power, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

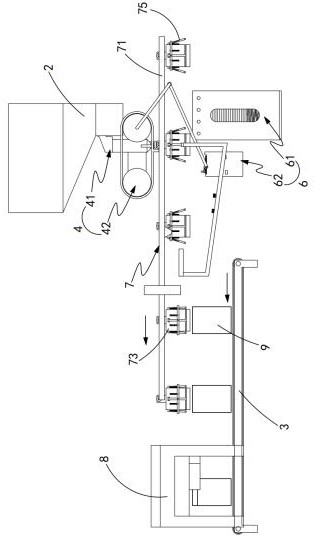

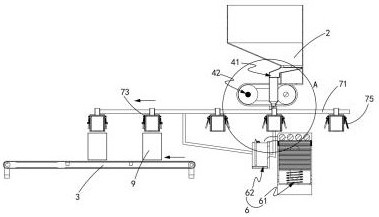

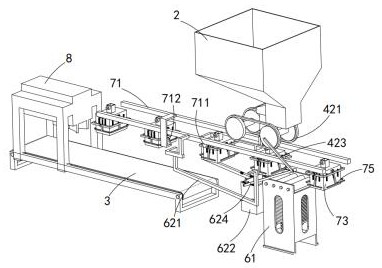

[0039] like Figure 1 to 9 As shown, a filling apparatus controlled by a chemical raw material is controlled, including a powder tank 2 and a transfer belt 3 disposed below the powder box 2, further comprising:

[0040] The filler mechanism 4, the filler mechanism 4 is disposed below the powder tank 2, and the filler mechanism 4 includes a substrate assembly 41 and a driving assembly 42 that acquires from the powder box 2. Quantitative powder, the drive assembly 42 drives the component 41 to move the output of the powder;

[0041] Dispensing mechanism 7, the dispensing mechanism 7 is disposed between the powder tank 2 and the transfer conveyor belt 3, the dispensing mechanism 7 includes a conveying line 71 and a binning bucket 73, the separated bucket 73 in the The conveying line 71 is equivalent to a plurality of arrays, and the separation tub 73 is operated below the drive assembly 42 driving the drive assembly 42 to move the substrate assembly 41 to the separated bucket 73. Mate...

Embodiment 2

[0061] Figure 10 A structural diagram of a filling apparatus controlled by a chemical raw material product of the present invention; Figure 10 As shown in, the same or corresponding components as in Example 1 adopts reference numerals corresponding to Embodiment 1, which is simply, and the difference points to the first embodiment are described below. The difference between this Example 2 and Example 1 is:

[0062] like Figure 10 As shown in the present embodiment, the free end of the clamping rod 751 is provided with a needle 753, and a needle plate 754 is provided on the side wall of the discharge barrel 73, and the pinhole plate 754 corresponds to the needle 753.

[0063] It should be noted that the needle plate 754 is fitted to the corresponding fit of the needle 753 such that the clamping rod 751 can be firmly clamped on the discharge barrel 73.

[0064] work process:

[0065] Transferring the processed powder material to the powder tank 2, the substrate assembly 41 acquires...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com