Low-energy-consumption flow-adjustable solid waste distributing system

A technology with low energy consumption and flow rate, which is applied in the direction of transportation and packaging, conveyor objects, conveyor control devices, etc., can solve problems such as unstable operation, large motor power, and high energy consumption, and achieve improved processing environment and energy consumption. The effect of reducing and high accuracy of flow control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

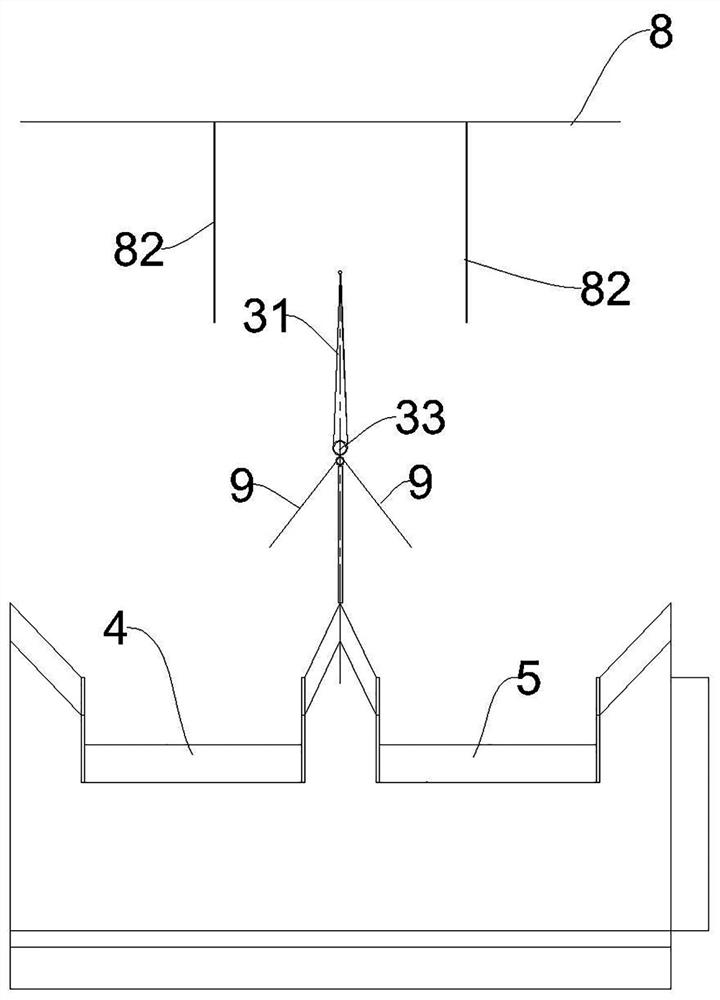

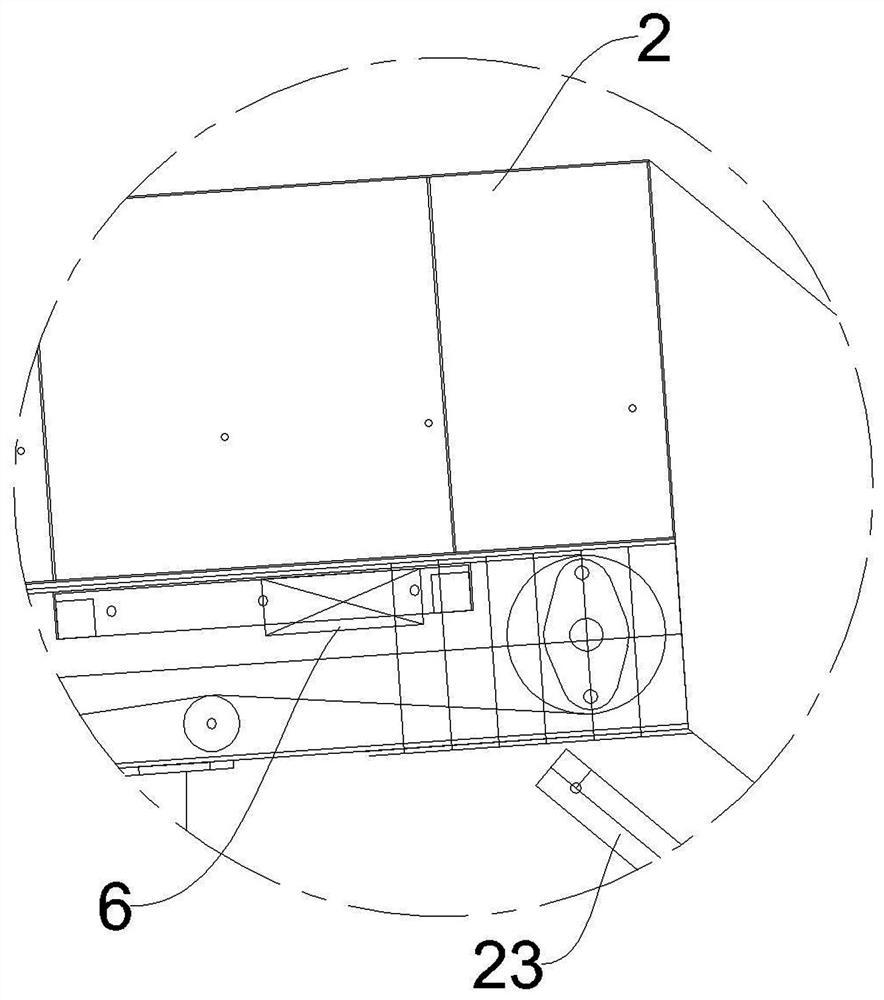

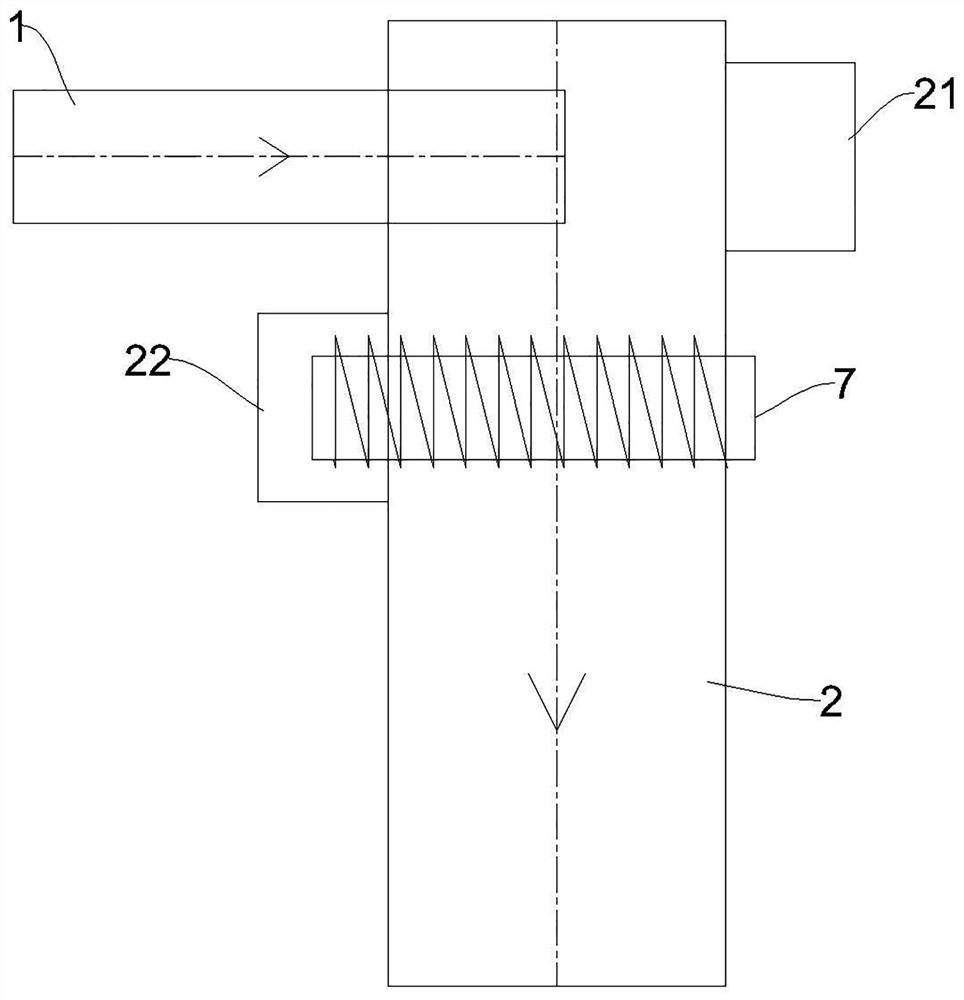

[0034] A solid waste sorting system with low energy consumption and adjustable flow, such as Figure 1-3 As shown, it includes a first conveyor belt 1, a second conveyor belt 2, a material distribution device 3, a distribution conveyor belt and a control system. The second conveyor belt 2 is arranged at the outlet end of the first conveyor belt 1, the second conveyor belt 2 has a receiving end and a discharge end, and the second conveyor belt 2 is from the receiving end to the discharge end. The end is inclined upward; the belt surface of the material receiving end is located below the outlet end of the first conveyor belt 1, and the discharge end is provided with a load cell 6; the shunt conveyor belt is set on the second The bottom of the conveyor belt 2 includes a third conveyor belt 4 and a fourth conveyor belt 5 arranged side by side for splitting the output material of the second conveyor belt 2; Between the conveyor belt 2 and the diverting conveyor belt; the load cell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com