Internal powder machine

A rack and vacuum technology, applied in the direction of conveyors, vibrating conveyors, conveyor objects, etc., can solve the problems of large particles or lumps of powder falling, poor economic benefits, short service life, etc., to avoid powder jamming Phenomenon, improvement of service life, effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

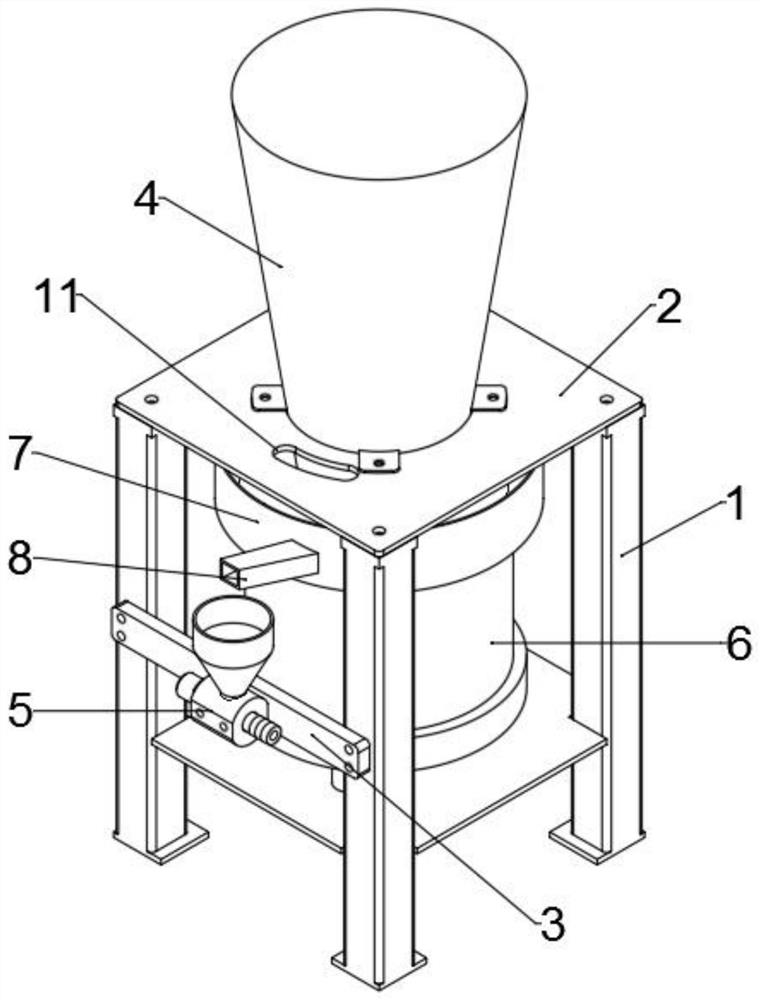

[0027] Such as figure 1 As shown, an internal powder machine proposed by the present invention includes a frame 1, an upper plate 2, a vacuum processor mounting frame 3, a hopper 4, a vacuum processor assembly 5, a vibrator 6, a vibrating plate assembly 7 and a discharge chute 8; the upper plate 2 is set on the frame 1; the hopper 4 is set on the upper plate 2; the vibrating plate assembly 7 driven by the vibrator 6 is set at the discharge end of the hopper 4; the discharge chute 8 is set on the vibrating plate assembly 7 The discharge end, the discharge chute 8 is located above the vacuum processor assembly 5; the vacuum processor mounting frame 3 is arranged on the frame 1; the vacuum processor assembly 5 is arranged on the vacuum processor mounting frame 3, and the vacuum processor assembly 5 includes a threaded rod 52; the threaded rod 52 is provided as a ceramic material.

[0028] In this embodiment, by setting the vibrator 6 and the vibrating plate assembly 7, the vibra...

Embodiment 2

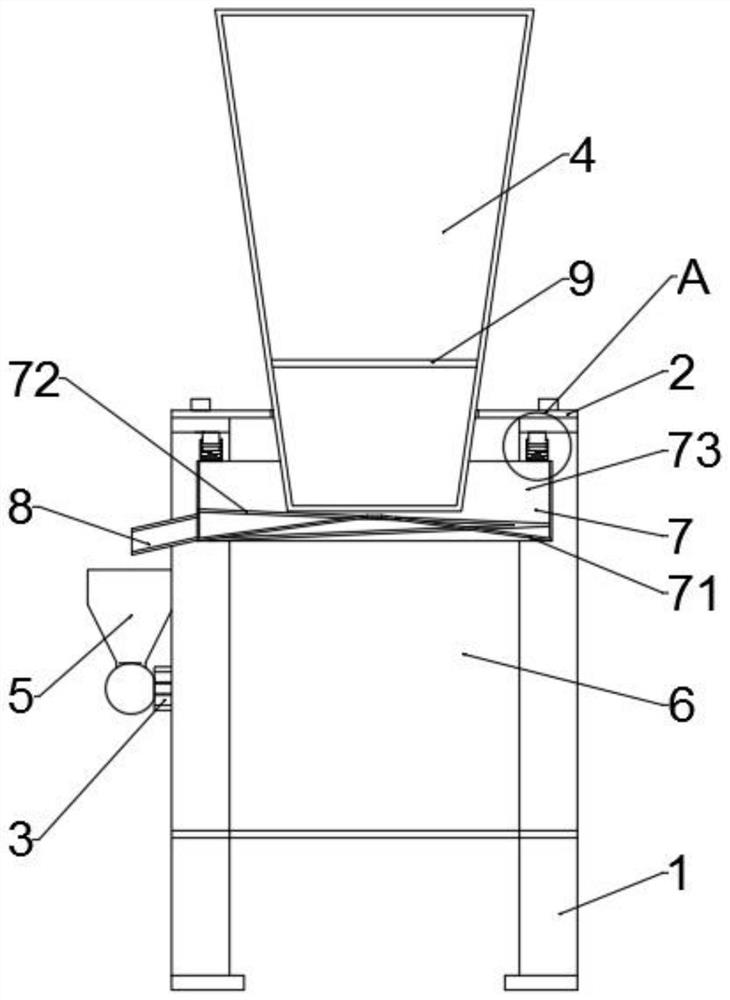

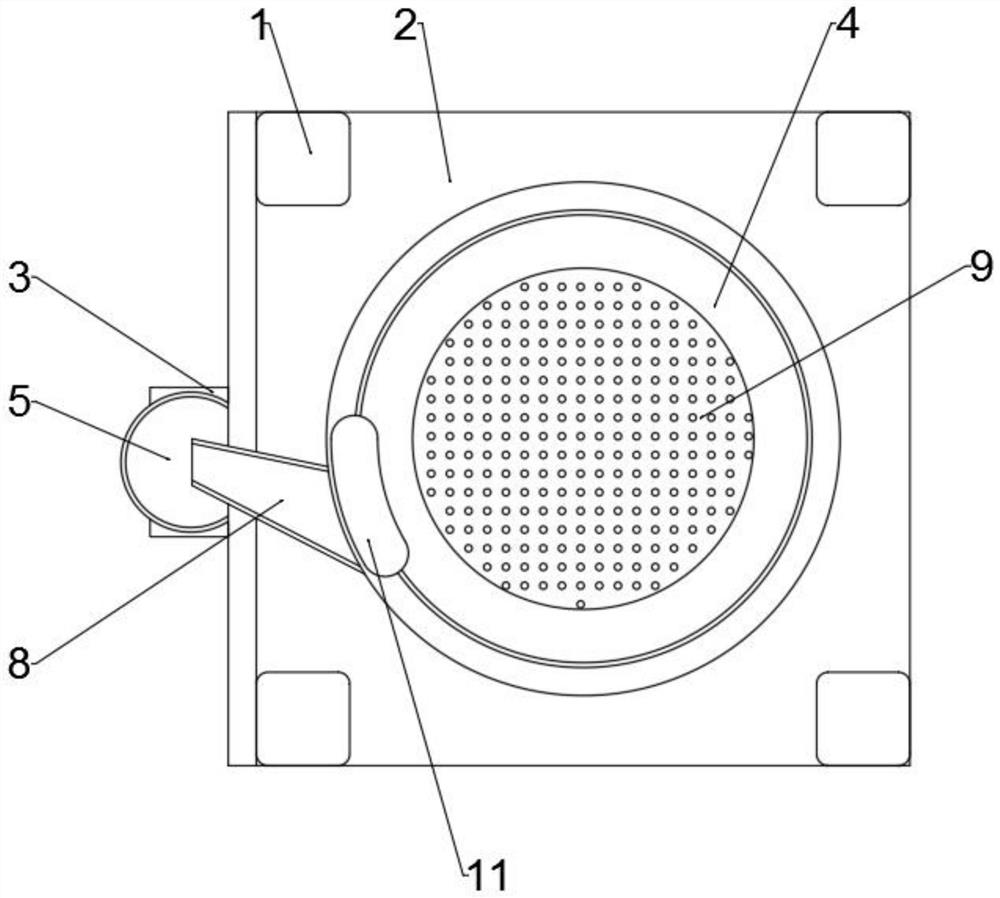

[0031] Such as Figure 1-2 As shown, the present embodiment proposes an internal powder machine. Compared with Embodiment 1, the vibration plate assembly 7 includes a material holding plate 71, a spiral frame 72 and a vibration plate 73; the material holding plate 71 and the spiral frame 72 are arranged on the vibration plate 73; the discharge end of the spiral frame 72 is arranged on the discharge end of the vibration plate 73, and is connected with the feed end of the discharge tank 8; the material holding plate 71 is arranged at the center of the spiral frame 72.

Embodiment 3

[0033] Such as figure 2 As shown, in the internal powder machine proposed in this embodiment, compared with Embodiment 2, the pitch of the screw frame 72 is 20 cm, the number of turns is 1, and the angle formed between the powder outlet end of the screw frame 72 and the horizontal plane is 13°.

[0034] In this embodiment, a spiral frame 72 is provided in the vibrating plate 73, the number of spiral turns is 1, and it rises in the vibrating plate with a pitch of 20; 13°, the powder will not become lumps, but the particles will be easily crushed into powder, and the powder will be conveyed evenly; the powder outlet will be tilted down, and the powder will not be piled up and conveyed smoothly and evenly, which is conducive to improving the efficiency of the internal powder machine. work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com