A rolling machine for electrical insulation tape

An electrical insulation and tape technology, applied in the direction of winding strips, thin material processing, coating, etc., can solve the problem of uneven distribution of electrical insulating tape glue, affecting the adhesion of electrical insulating tapes, and poor glue coating of polyvinyl chloride films. sufficient and other problems to avoid uneven distribution of glue, extend the drying path, and facilitate replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In conjunction with the following drawings, embodiments of the present invention will be described in detail, but the present invention can be defined by the claims, and many different embodiments of cover.

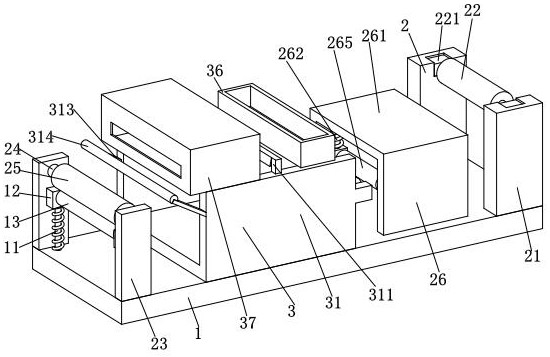

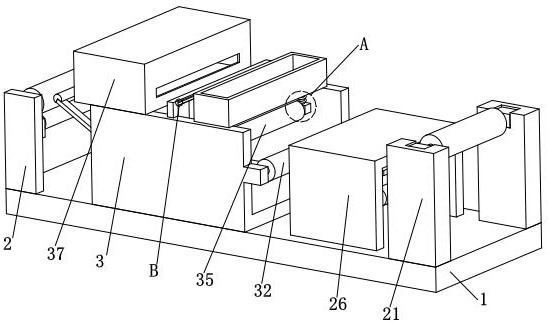

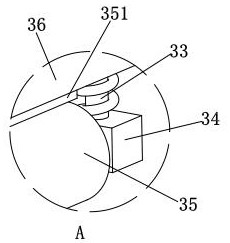

[0030] See figure 1 , image 3 , Figure 5 , One kind of the electrical insulating tape into a roll winding machine, comprising a bottom frame 1, the transport mechanism 2 and the gluing means 3, the conveying mechanism 2 mounted on the bottom end surface of the left and right sides of the frame 1, the bottom frame 1 end surface and the conveying mechanism 3 is mounted between two gluing mechanism.

[0031] The conveying means 2 comprises a conveying rack 21, the conveying roller 22, the winding frame 23, the motor winding 24, the winding roller 25 and a smooth branched 26, wherein said longitudinal conveying rack 21 mounted symmetrically the bottom end surface of the frame 1 on the right side, is provided with a transport rack 21 between the transport roller 22, the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com