Non-sintered antimony tailing brick and preparation process thereof

A preparation process, non-sintering technology, applied in the field of solid waste resource utilization, can solve the problems of environmental secondary pollution, environmental heavy metal pollution, hidden dangers, etc., and achieve the effects of improving the ecological environment, reducing porosity, and increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

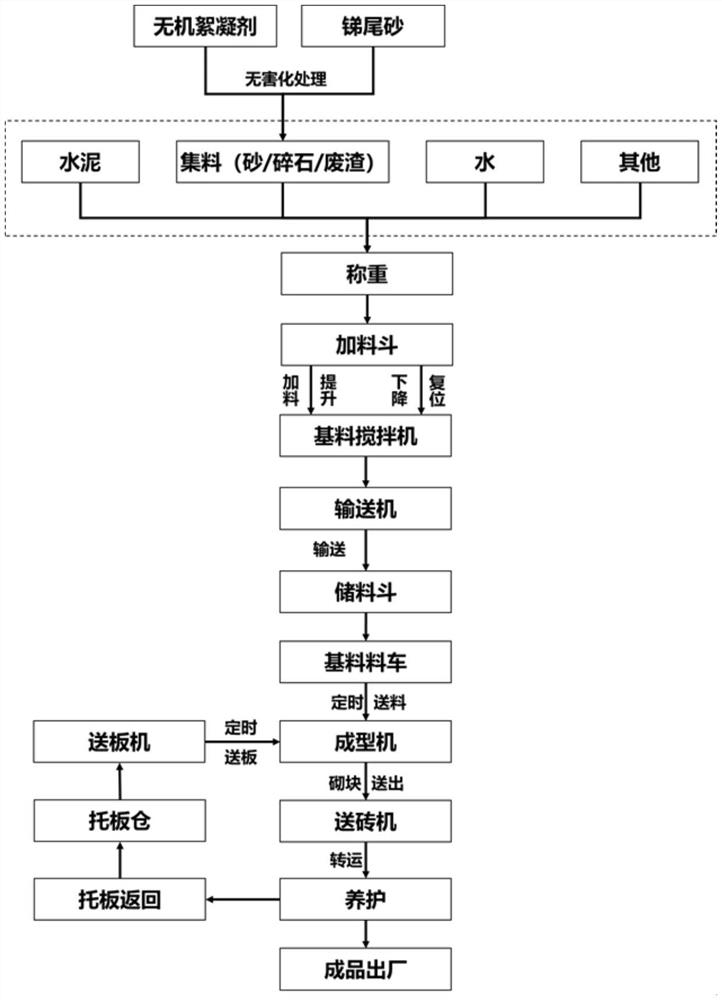

Image

Examples

Embodiment 1

[0020] A non-sintered antimony tailings brick, comprising the following components: 50% aggregate, 40% tailings, 8% cement-based material, 2% water and 0.1% inorganic flocculant.

[0021] The main component in the tailings is SiO 2 , Fe 2 o 3 、Al 2 o 3 .

[0022] The inorganic flocculant is polyferric sulfate.

[0023] The cement-based material includes fly ash, silica fume and cement.

[0024] A preparation process for non-sintered antimony tailings bricks, comprising the following steps:

[0025] (1) Solidification treatment: Dissolve polyferric sulfate directly in the water used for mixing, configure it into a 0.1% polyferric sulfate solution, fully stir it with the tailings, let it stand for 1-2h, make it fully react, and realize harmful heavy metal elements of solidification.

[0026] (2) Mixing and stirring: add 50% aggregate, 40% solidified tailings, 8% cement-based material and 2% water to a base material mixer and fully stir to obtain a mixture.

[0027] (3) ...

Embodiment 2

[0031] A non-sintered antimony tailings brick, comprising the following components: 55% aggregate, 35% tailings, 8% cement-based material, 2% water and 0.1% inorganic flocculant.

[0032] The main component in the tailings is SiO 2 , Fe 2 o 3 、Al 2 o 3 .

[0033] The inorganic flocculant is polyferric sulfate.

[0034] The cement-based material includes fly ash, silica fume and cement.

[0035] A preparation process for non-sintered antimony tailings bricks, comprising the following steps:

[0036] (1) Solidification treatment: Dissolve polyferric sulfate directly in the water used for mixing, configure it into a 0.1% polyferric sulfate solution, fully stir it with the tailings, let it stand for 1-2h, make it fully react, and realize harmful heavy metal elements of solidification.

[0037] (2) Mixing and stirring: add 55% aggregate, 35% solidified tailings, 8% cement-based material and 2% water to a base material mixer and fully stir to obtain a mixture.

[0038] (3) ...

Embodiment 3

[0042] A non-sintered antimony tailings brick, comprising the following components: 45% aggregate, 45% tailings, 8% cement-based material, 2% water and 0.1% inorganic flocculant.

[0043] The main component in the tailings is SiO 2 , Fe 2 o 3 、Al 2 o 3 .

[0044] The inorganic flocculant is polyferric sulfate.

[0045] The cement-based material includes fly ash, silica fume and cement.

[0046] A preparation process for non-sintered antimony tailings bricks, comprising the following steps:

[0047] (1) Solidification treatment: Dissolve polyferric sulfate directly in the water used for mixing, configure it into a 0.1% polyferric sulfate solution, fully stir it with the tailings, let it stand for 1-2h, make it fully react, and realize harmful heavy metal elements of solidification.

[0048] (2) Mixing and stirring: add 45% aggregate, 45% solidified tailings, 8% cement-based material and 2% water to a base material mixer and fully stir to obtain a mixture.

[0049] (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com