Low-carbon rapid maintenance and pavement method for asphalt pavement ruts

A technology of asphalt pavement and asphalt surface layer, which is applied in the field of asphalt pavement rutting low-carbon rapid maintenance pavement, which can solve the problems of long demulsification time and affecting the opening time of traffic, etc., to improve the anti-rutting performance and adjust the demulsification time Excellent effect of controllable, temperature and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

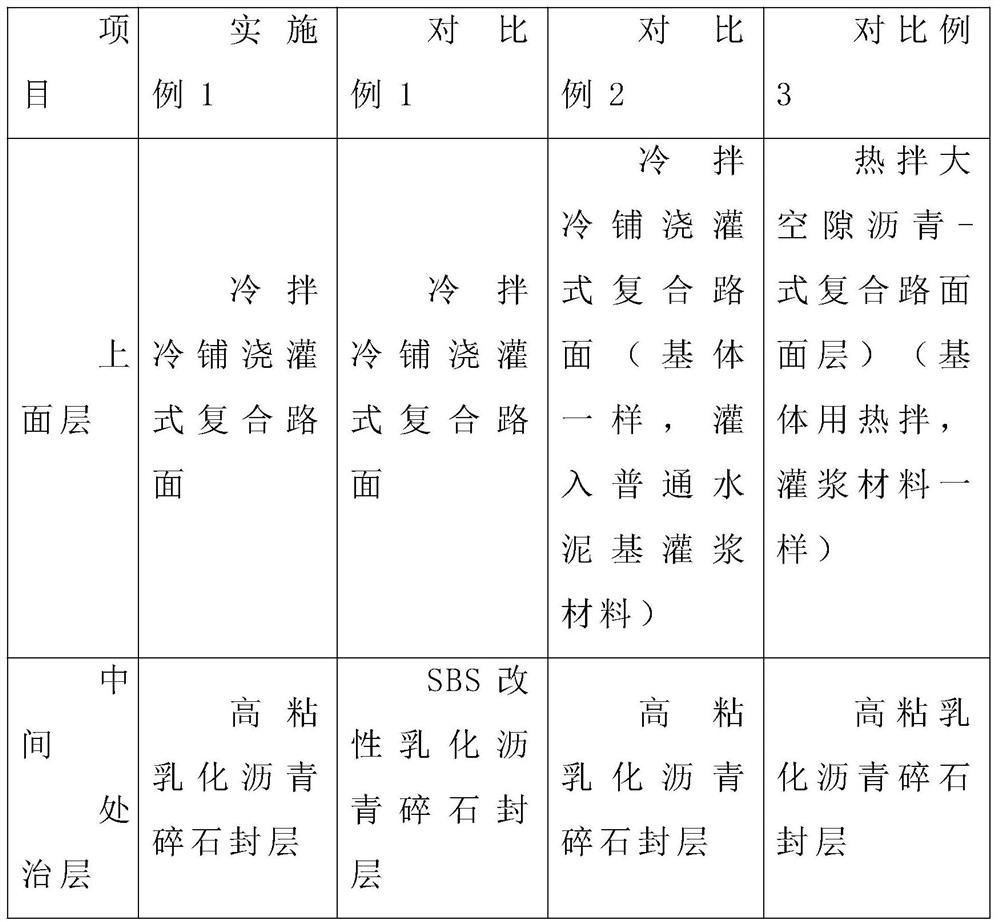

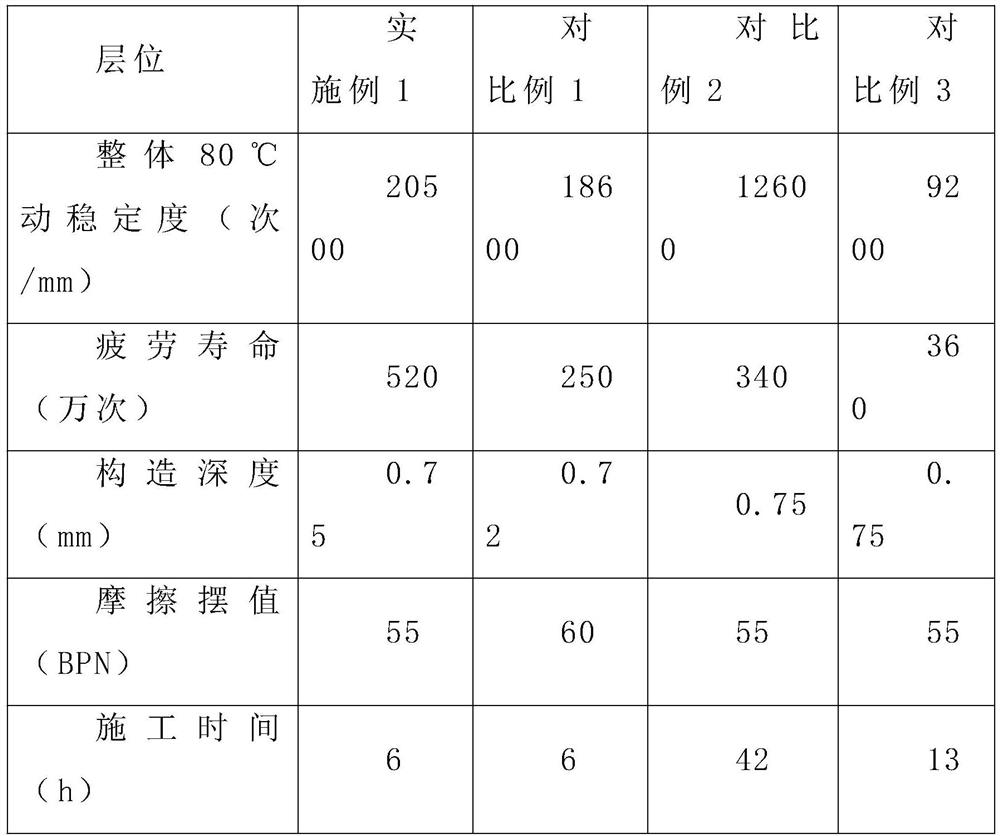

Embodiment 1

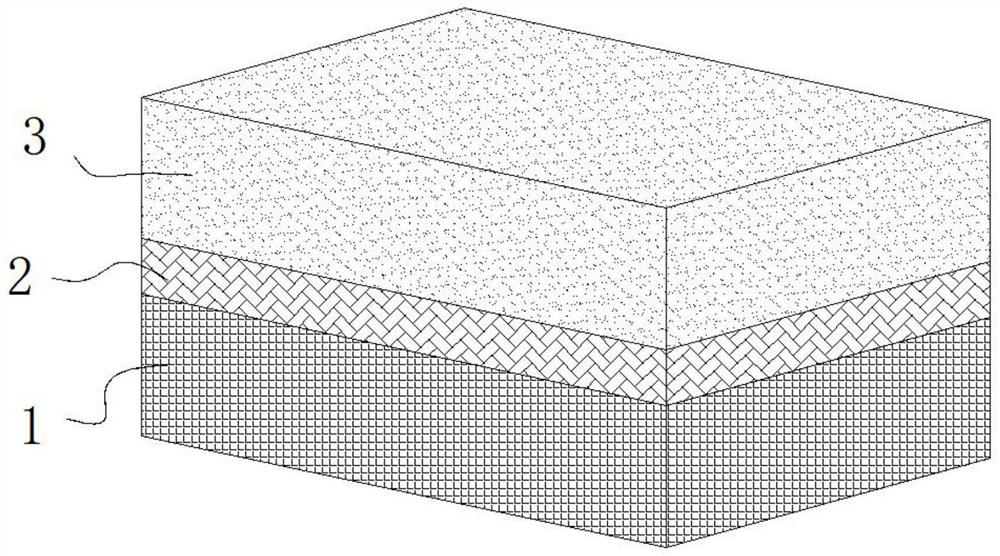

[0031] Such as figure 1 Shown, a kind of municipal road rutting low-carbon rapid maintenance pavement method, comprises the following steps:

[0032] 1) Asphalt surface layer milling: use a milling machine to mill the asphalt surface layer until the original pavement base layer is exposed. If there are cracks in the base layer, it needs to be filled;

[0033] 2) Paving of high-viscosity emulsified asphalt gravel seal layer: After the milling of the asphalt surface layer of the original pavement is completed, the surface of the base layer shall be cleaned, dried in the sun, and cracks and other diseases of the base layer shall be treated. Pave high-viscosity modified emulsified asphalt, the spreading amount of high-viscosity modified emulsified asphalt is 2.5kg / m2; the spreading amount of crushed stone is 6kg / m2; Viscosity 250000Pa.s;

[0034] 3) Pavement of cold-mixed and cold-paved pouring composite pavement surface;

[0035] The pavement of cold-mixed and cold-paved poura...

Embodiment 2

[0064] A municipal road rut maintenance pavement method, comprising the following steps:

[0065] 1) Asphalt surface layer milling: use a milling machine to mill the asphalt surface layer until the original pavement base layer is exposed. If there are cracks in the base layer, it needs to be filled;

[0066] 2) Paving of high-viscosity emulsified asphalt gravel seal layer: After the milling of the asphalt surface layer of the original pavement is completed, the surface of the base layer shall be cleaned, dried in the sun, and cracks and other diseases of the base layer shall be treated. Spread SBS modified emulsified asphalt, the spread amount of SBS modified emulsified asphalt is 3.0kg / m2; the amount of gravel spread is 8kg / m2; the solid content of high viscosity modified emulsified asphalt is 65%, and the dynamic viscosity of the evaporation residue at 60°C is 350000Pa .s;

[0067] 3) Pavement of cold-mixed and cold-paved pouring composite pavement surface;

[0068] The pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com