Infrared and visible light camera synchronous calibration device and calibration method thereof

A calibration device and visible light technology, applied in the field of infrared cameras, can solve problems such as poor imaging effect and complicated synchronous calibration device, and achieve the effect of simple structure, saving labor cost and time cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The technical scheme that the present invention solves the problems of the technologies described above is as follows:

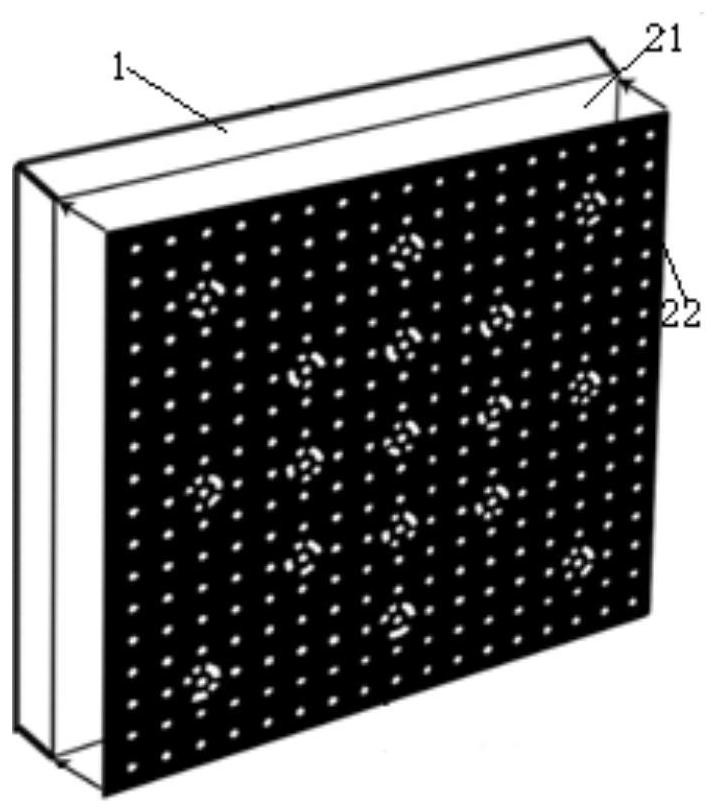

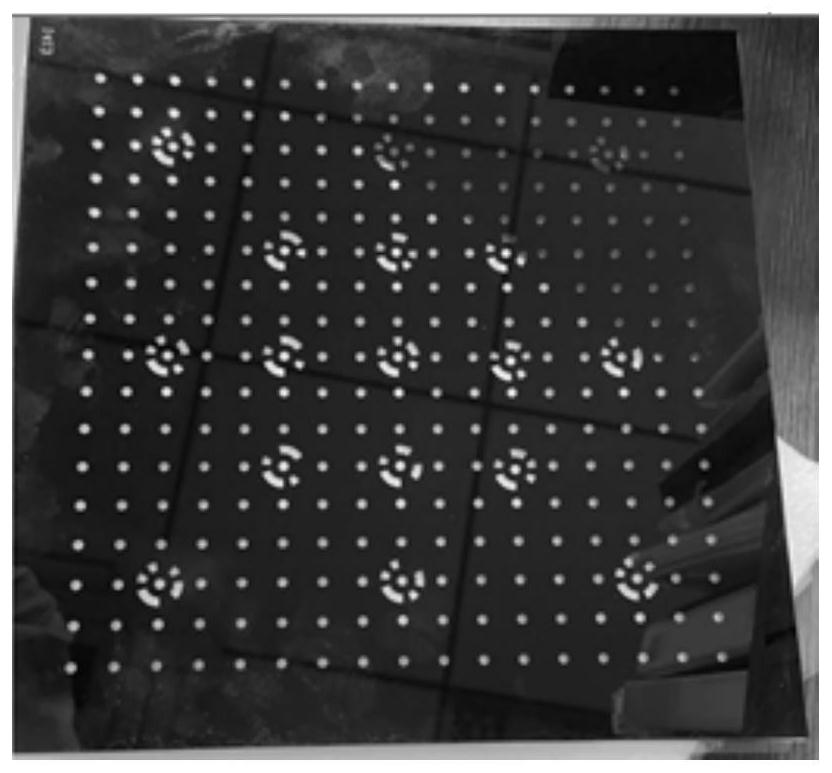

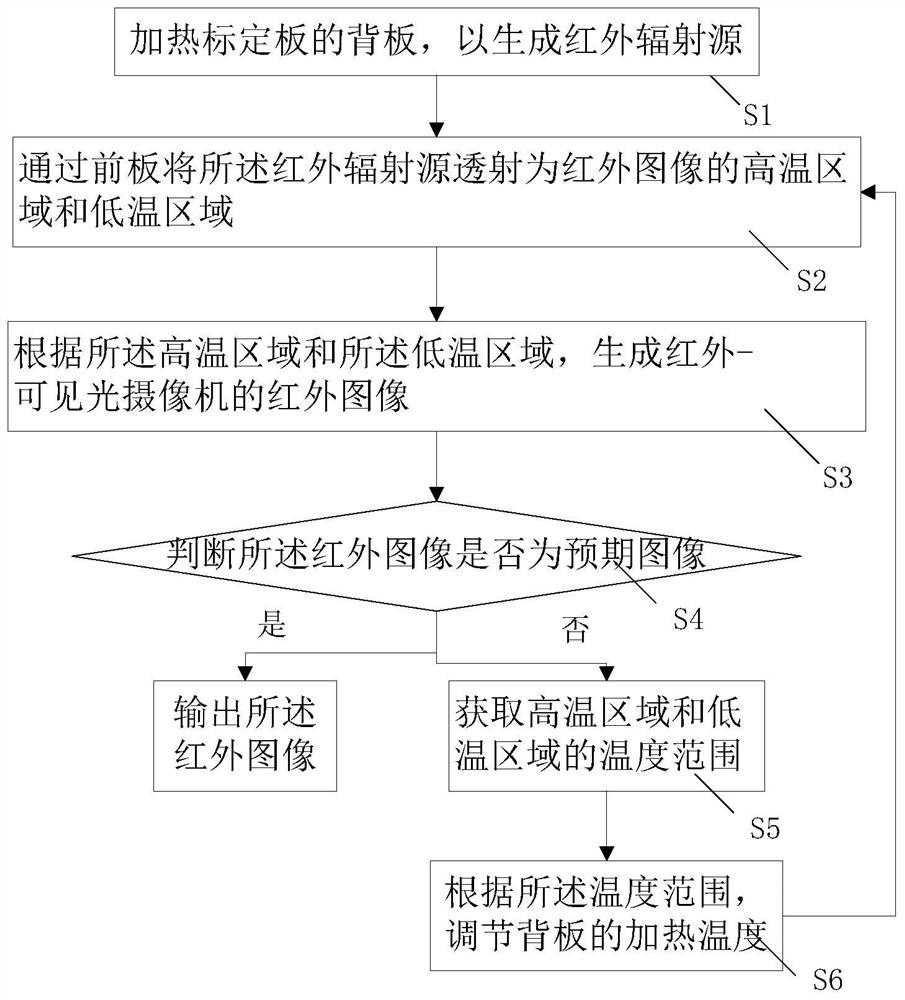

[0030] The present invention provides a synchronous calibration device for infrared and visible light cameras, referring to figure 1 and figure 2 As shown, the infrared and visible light camera is used to collect infrared radiation to form a synchronous infrared and visible light image, the infrared and visible light camera synchronous calibration device includes a calibration plate, the calibration plate includes a front plate and a back plate 1, the The front plate is attached to the back plate 1 and the back plate 1 is used to generate an infrared radiation source. The front plate includes an infrared shielding area and an infrared transmission area, and the infrared shielding area absorbs part of the heat of the infrared radiation source To form the low temperature region of the simultaneous infrared and visible light image, the infrared transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com