Winding method of double-layer fractional-slot concentrated winding of motor

A double-layer fractional slot, concentrated winding technology, applied in the shape/style/structure of the winding conductor, can solve the problem of low winding efficiency, and achieve the effect of saving rotation time, high work efficiency, and high winding work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

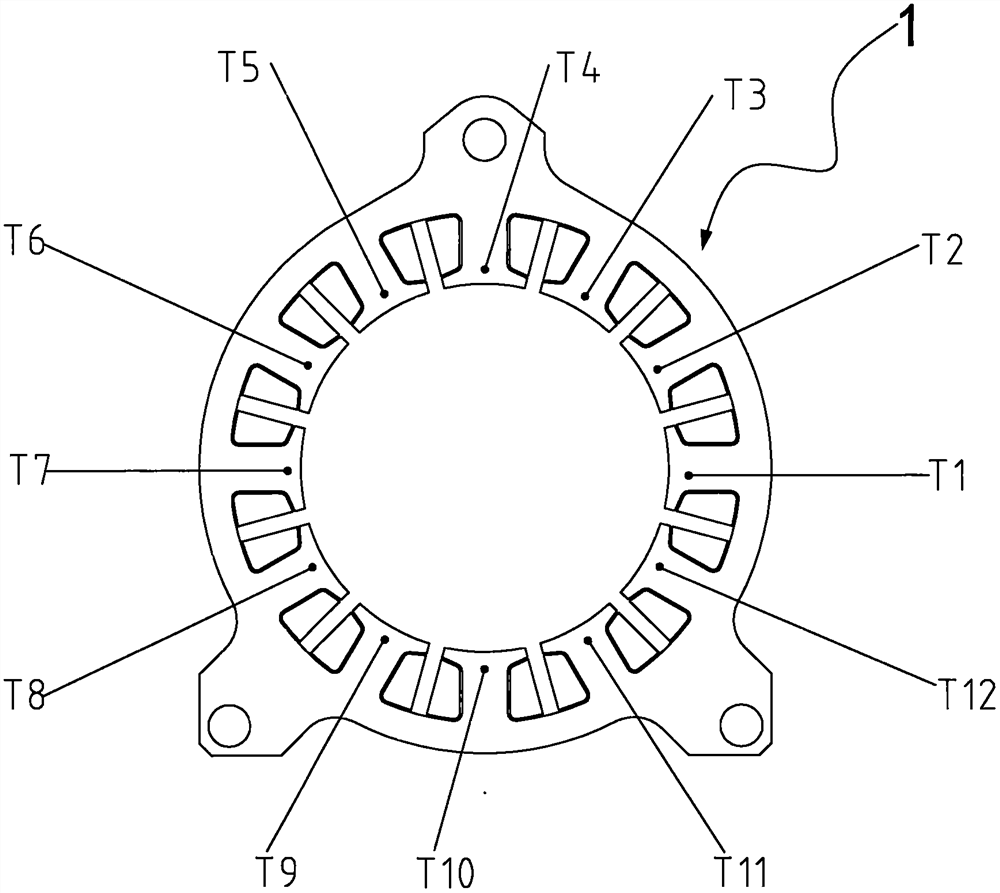

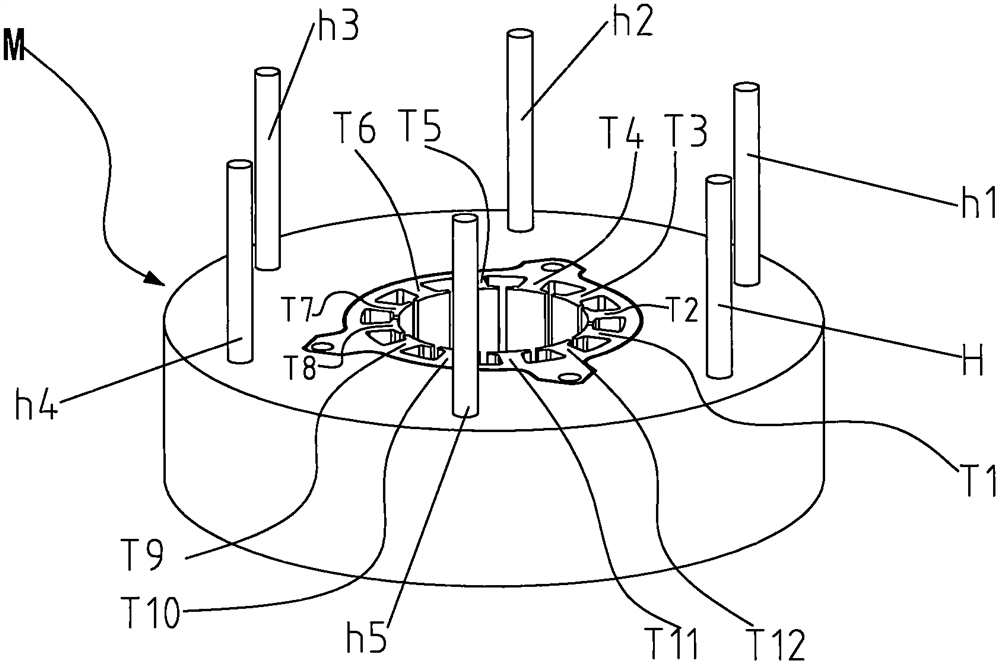

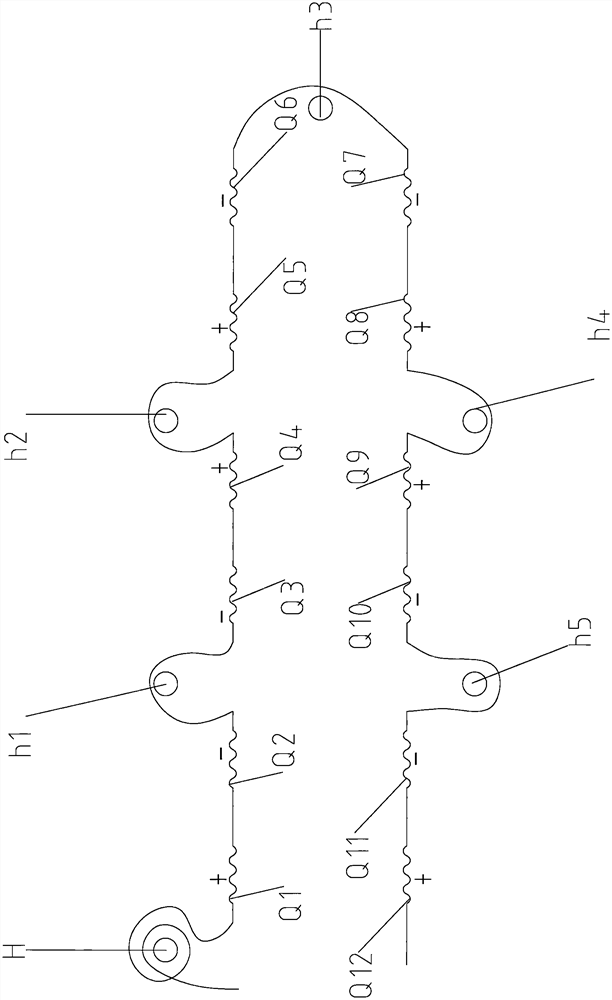

[0018] see Figure 1~3 As shown, a winding method of a double-layer fractional slot concentrated winding of a motor, the motor is a 12-slot, 10-pole three-phase motor, the number of slots per pole and phase of the motor is 2 / 5, and the stator core 1 is fixed on a single-pin winding In the winding tool M of the wire machine, the winding is carried out on the single-needle winding machine using a single-axis enameled wire reel. On the starting column H of the winding tooling M of the winding machine, the same enameled wire is arranged in sequence on the stator core 1, the first winding tooth T1, the second winding tooth T2, the third winding tooth T3, the third winding tooth 4 winding teeth T4, 5th winding teeth T5, 6th winding teeth T6, 7th winding teeth T7, 8th winding teeth T8, 9th winding teeth T9, 10th winding teeth T10, 11th winding teeth The winding tooth T11 and the 12th winding tooth T12 are wound sequentially to obtain the first coil Q1, the second coil Q2, the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com