Automatic feeding machine for tube feeding of patients with dysphagia

An automatic feeding and dysphagia technology, which is applied in the field of medical devices, can solve the problems of eating and drinking, polluting the environment, uneven injection speed, too slow and delaying time, etc., and achieves a solid connection, reliable and light structure, and simple and fast operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The principles and features of the present invention will be described below with reference to the accompanying drawings, and the exemplary examples are intended to be construed as not intended to limit the scope of the invention.

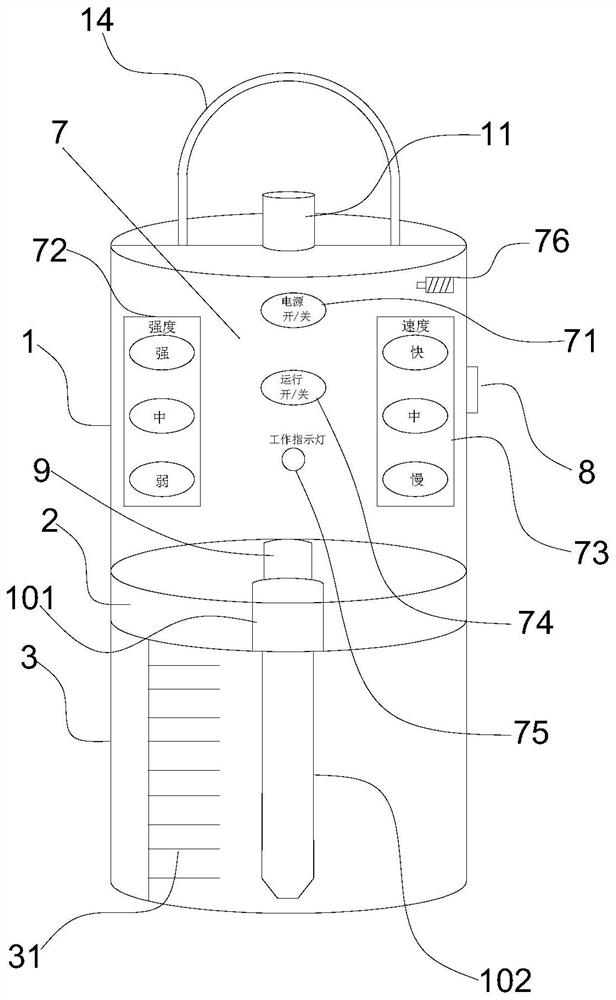

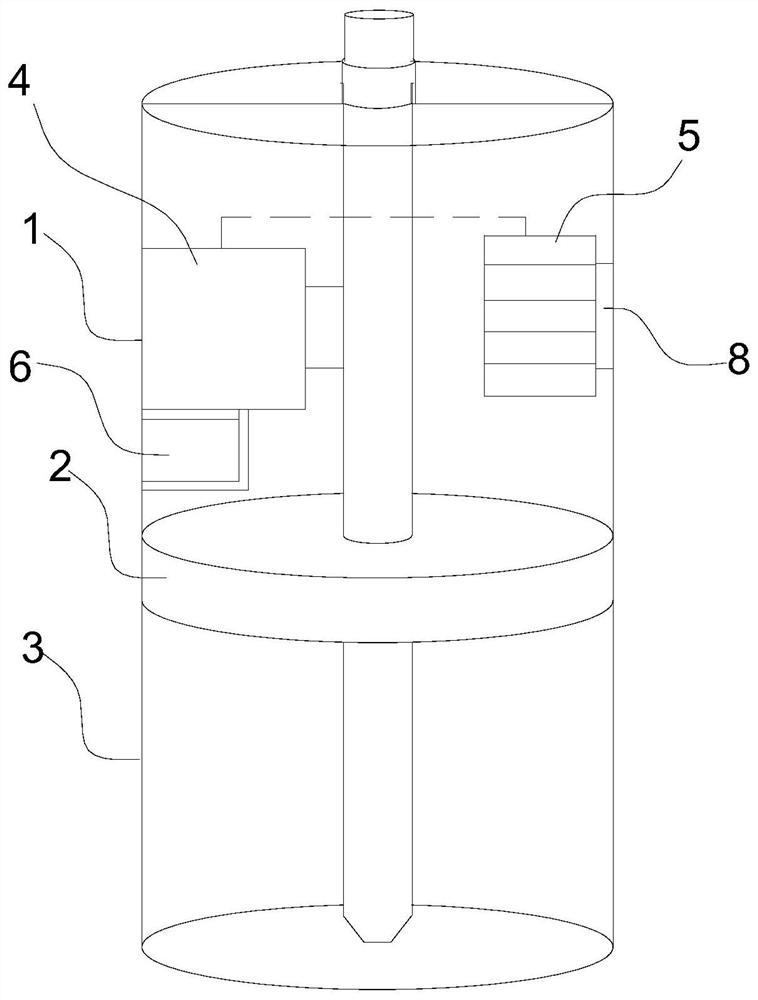

[0023] like Figure 1 to 2 As shown in a tube feeding patients with dysphagia automatic feeding machine, comprising a main box body 1 is provided at a lower end of the main box body 1 and the insulating cover 2 provided on the lower end of the insulating cover 2 food cups 3. The bottom of the main box body 1 is provided with a feeding port 9 connected to the feeding tube 10 and the top 11 is provided with an outlet connected to a food esophagus 12, the tube 12 is connected esophagus 13.

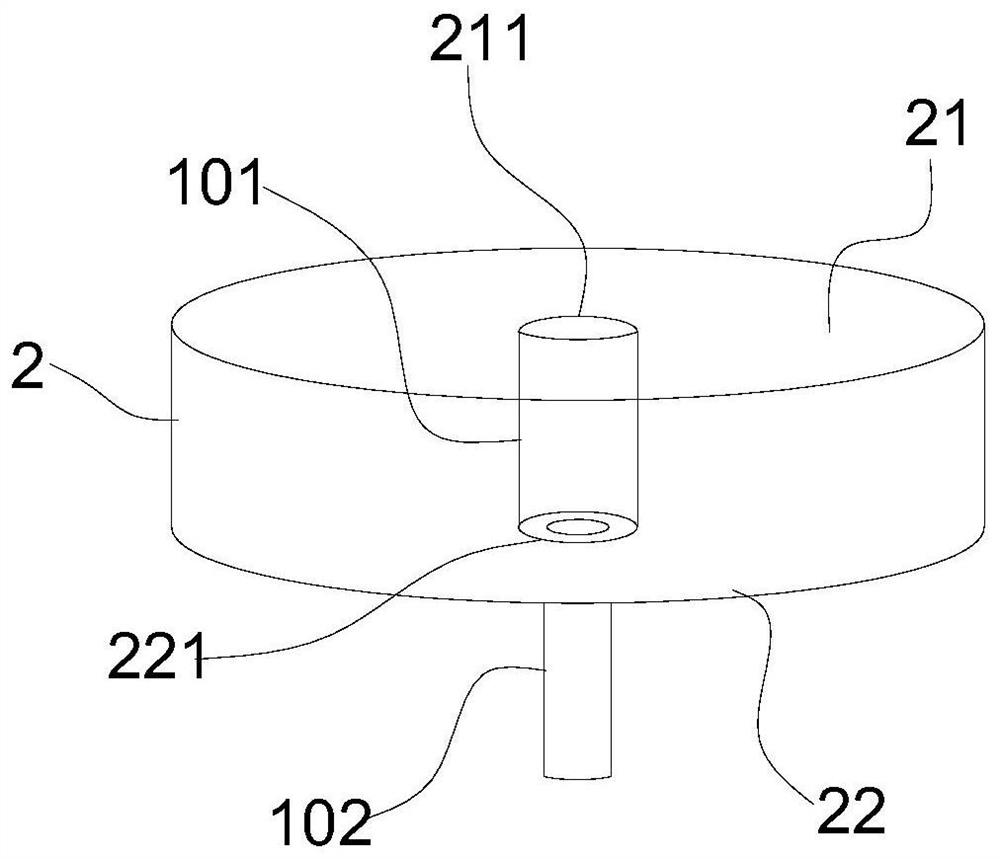

[0024] The lower end of the inner wall of the main box body 1 defines a helical slot, the coil insulating cover and the coil pattern card slot adapted to the upper end of the outer wall 2 is provided with; insulating cover the lower end of the inner wall 2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com