Laser cutting device for cutting small nameplates

A laser cutting and nameplate technology, applied in laser welding equipment, other manufacturing equipment/tools, welding equipment, etc., can solve the problems of low positioning accuracy and abnormal cutting, so as to increase positioning accuracy, avoid defective products, and avoid inaccuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

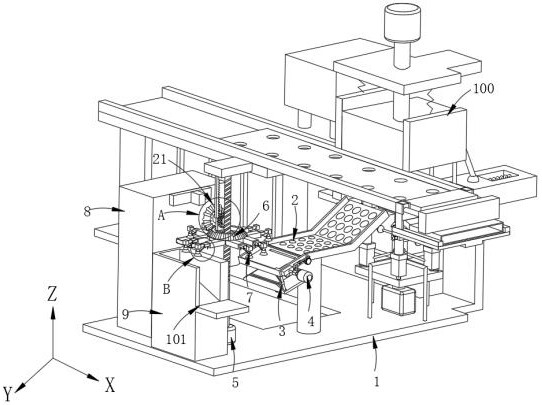

[0098] Such as figure 1 As shown, a laser cutting device for cutting small nameplates, including:

[0099] Main board 1,

[0100] stamping system 101, the stamping system 101 is connected with the main panel 1; and

[0101] A laser cutting system 102, the laser cutting system 102 is located at the discharge end of the stamping system 101;

[0102] The output end of the stamping system 101 is connected with a ball slideway 2, and its surface is rotated with several rolling elements; the positioning frame 35 is rotated and set at the discharge end of the ball slideway 2;

[0103] When the stamping device of the nameplate plate on the main plate 1 is stamped, it will fall on the ball slideway 2 at this time. Since the ball slideway 2 is equipped with rolling balls, the nameplate plate will move along the rolling balls under the action of gravity. Slide into the positioning frame 35;

[0104] Laser cutting system 102 includes:

[0105] Adjustment component 3, the adjustment c...

Embodiment 2

[0128] Such as Figure 5-13 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

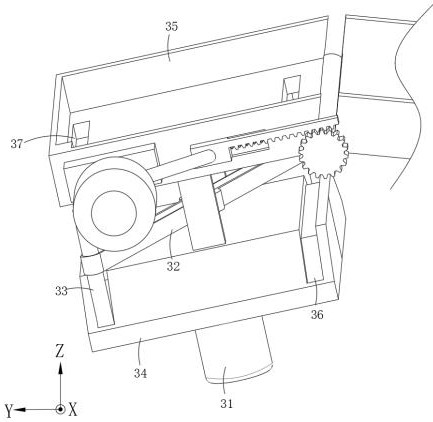

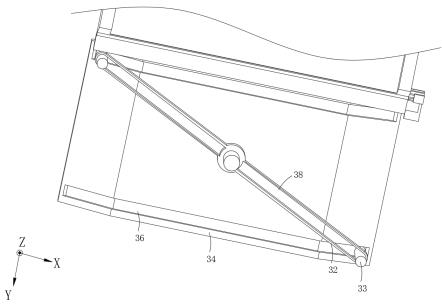

[0129] Such as Figure 5 As shown, preferably, the transmission assembly 21 includes:

[0130] a drive assembly 5, the drive assembly 5 is connected to the main board 1; and

[0131] The steering assembly 6, the steering assembly 6 switches the nameplate captured by the adsorption assembly 7 to different stations;

[0132] Such as Figure 5 As shown, preferably, the drive assembly 5 includes:

[0133] A driving motor 51, which is arranged above the main board 1;

[0134] Drive screw mandrel 52, it is arranged on the output end of drive motor 51;

[0135] A driving wire block 53, the inside of which engages ...

Embodiment 3

[0159] Such as Figure 14-19 As shown, the parts that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between this embodiment two and embodiment one is:

[0160] Such as Figure 14 As shown, preferably, the stamping system 101 includes:

[0161] Rack 1001;

[0162] Also includes:

[0163] stamping assembly 1002, which is connected to the frame 1001;

[0164] The second positioning component 1003 is arranged inside the frame 1001;

[0165] Grinding assembly 1004, which is arranged on the top of the second positioning assembly 1003;

[0166]When the nameplate is stamped and moves downward, the second positioning assembly 1003 provides a driving force to drive the grinding assembly 1004 to expand upward, thereby completing the positioning of the nameplate, and the namepl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com