Vibration suppression method and device of vehicle engine, storage medium and vehicle

A technology of vibration suppression and engine controller, which is applied in the direction of engine starting, engine control, and engine motor starting, etc., which can solve the problems of large engine changes and high design costs, and achieve improved fuel economy and power performance with low cost , The effect of engine modification is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

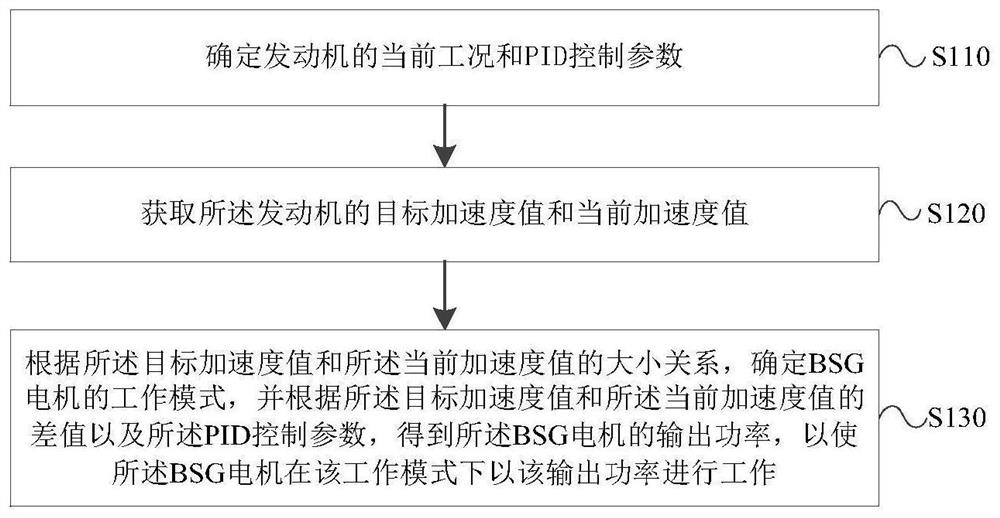

[0041] see figure 1 The present application provides a method for suppressing vibration of a vehicle engine applied to a vehicle, and when the method for suppressing vibration of a vehicle engine is applied to the vehicle, step S110-step S130 is performed.

[0042] Step S110: Determine the current working condition and PID control parameters of the engine.

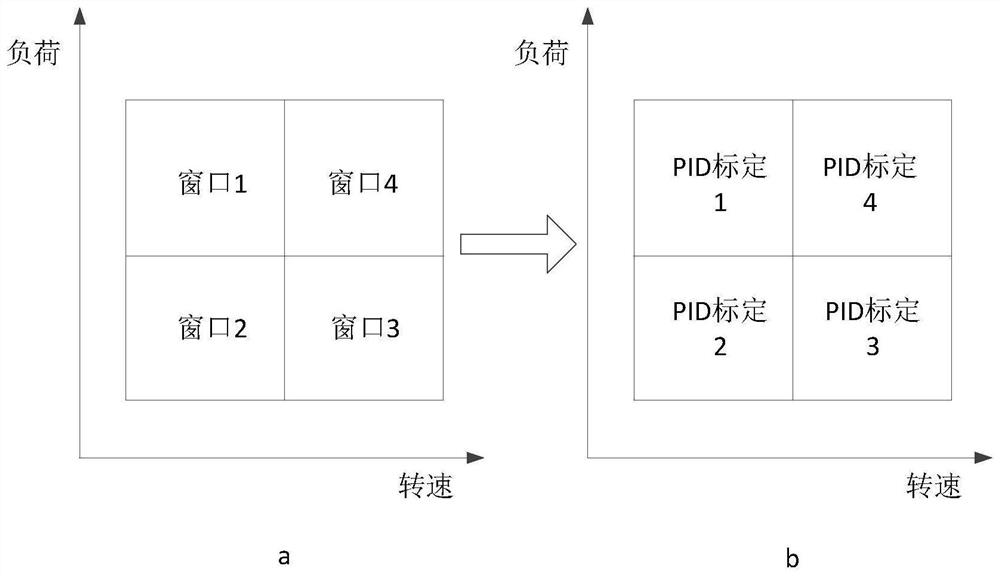

[0043] In this embodiment, the operating conditions of the engine are classified according to the magnitude of the engine speed and load. Please combine figure 2 In the diagram a, the abscissa represents the rotational speed, and the ordinate represents the load. The operating conditions of the engine include low-speed large load, low-speed small load, high-speed small load and high-speed large load, namely figure 2 The four windows shown in figure 2 The abscissa and ordinate in , it can be obtained that the low-speed large load is window 1, the low-speed small load is window 2, the high-speed small load is window 3,...

Embodiment 2

[0061] This embodiment also provides a storage medium, such as a flash memory, a hard disk, a multimedia card, a card-type memory (for example, SD or DX memory, etc.), random access memory (RAM), static random access memory (SRAM), read-only memory ( ROM), Electrically Erasable Programmable Read-Only Memory (EEPROM), Programmable Read-Only Memory (PROM), magnetic memory, magnetic disk, optical disk, server, App application store, etc., on which computer programs are stored, and the computer When the program is executed by the processor, all or part of the steps of a method for suppressing vibration of a vehicle engine as in the embodiment can be realized. For the specific implementation process of all or part of the steps of the vibration suppression method for the vehicle engine mentioned above, please refer to Embodiment 1, and this embodiment will not be repeated here.

Embodiment 3

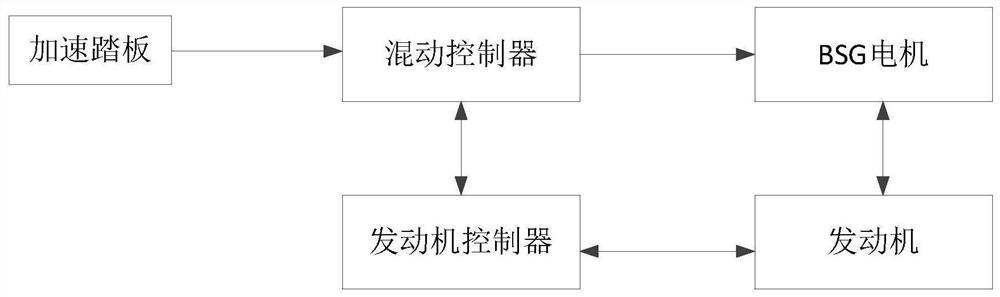

[0063] see image 3 An embodiment of the present application provides a vehicle, including an engine, a BSG motor, and an engine control device, wherein the engine control device includes an engine controller and a hybrid controller.

[0064] In this embodiment, the BSG motor is connected to the engine through a belt, and the engine controller is connected to the engine to obtain the current rotational speed of the engine, differentiate the current rotational speed, and obtain the current acceleration value, and Send this current acceleration value to the hybrid controller.

[0065] The hybrid controller is connected with the BSG motor and the engine controller. The hybrid controller receives the acceleration request, as well as the current speed, current load and current acceleration value sent by the engine controller. The acceleration request carries the target acceleration value that the driver wants to achieve by stepping on the accelerator pedal, and combines the target...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com