A packaging production line for steel wire rope production and processing

A packaging production line and steel wire rope technology, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of wire rope packaging production line defects, wire rope paint damage, paint loss of function and protection, etc., to ensure that the roll The effect of winding tightness, improving the shaping effect, and improving the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

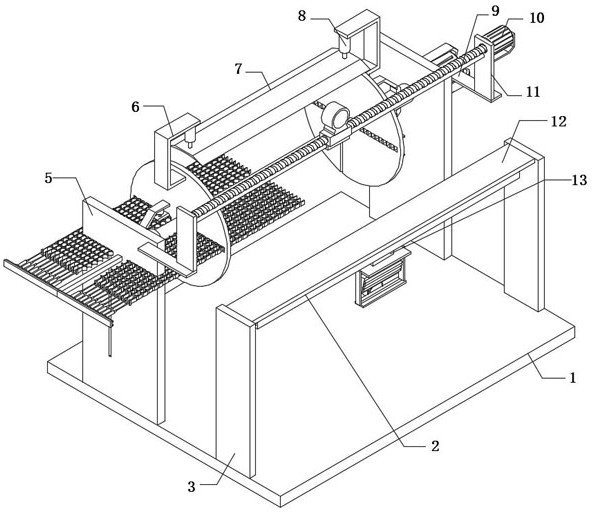

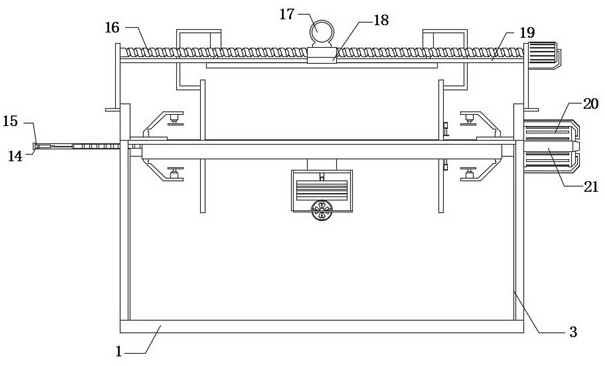

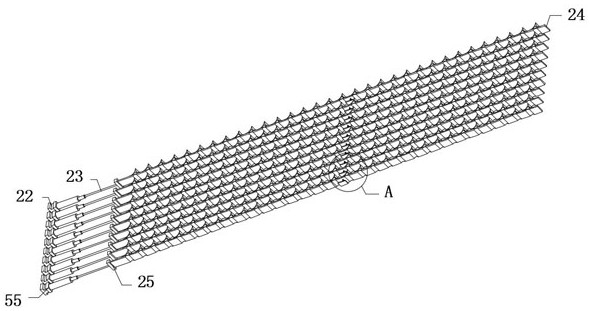

[0031] Refer Figure 1-4A wire rope packaging line production and processing, comprises a base 1 and a shaped wheel 40, the top ends of the outer wall of the base 1 are fixedly connected with a fixing plate 5, and the outer wall of the fixed plate 5 and the two uniformly shaped wheel 40 a distance apart perforation 47, an outer wall of one side of the fixing plate 5 is fixedly connected with a T-rail 14, and both ends of the T-rail side of the outer wall 14 are fixedly connected to the adapter rails 15, two rails adapted to slide 15 from the inner wall of uniformly since the slider 22 is connected to each of the slider from the outer wall 22 are fixedly connected with a fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com