Compact AGV frame and AGV forklift

A compact and frame technology, applied in the field of frame, can solve the problems of large body length, AGV forklift turning radius and large channel width, etc., and achieve the effect of compact frame, increased rigidity and small width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

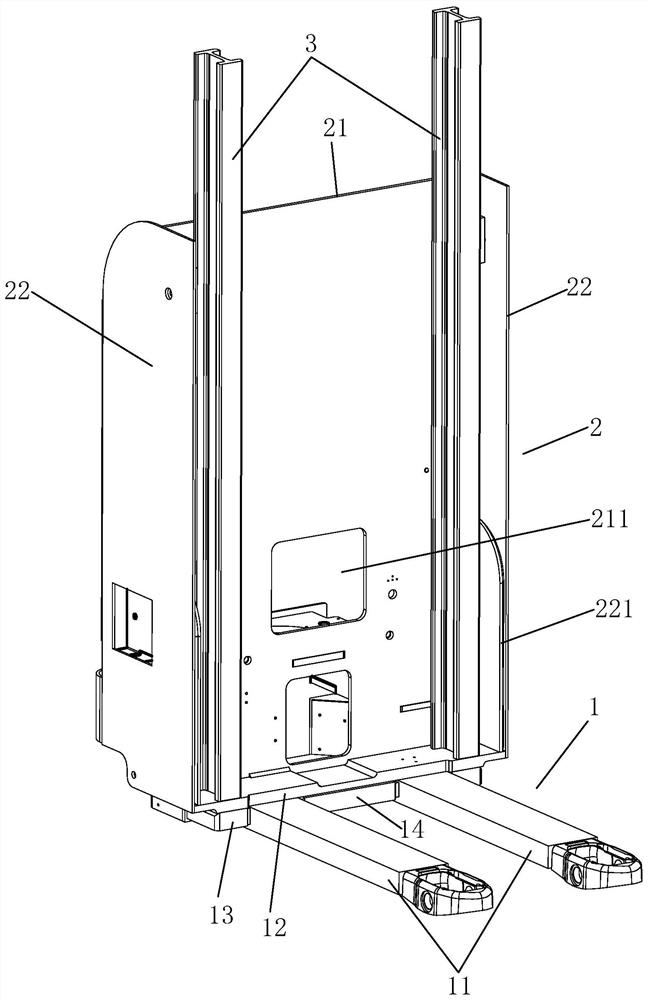

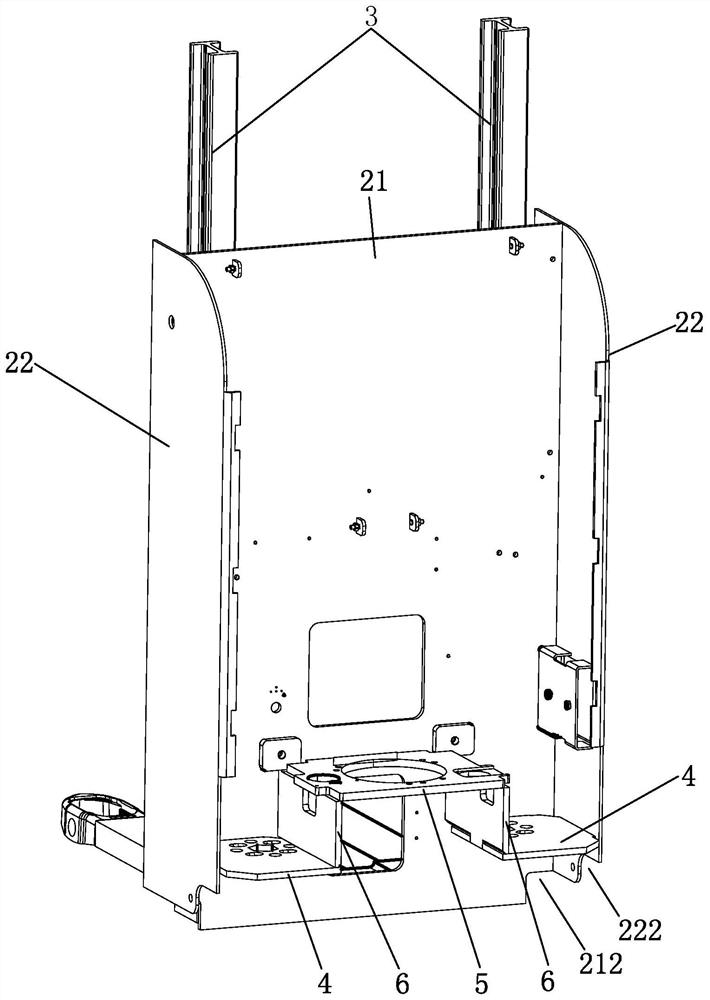

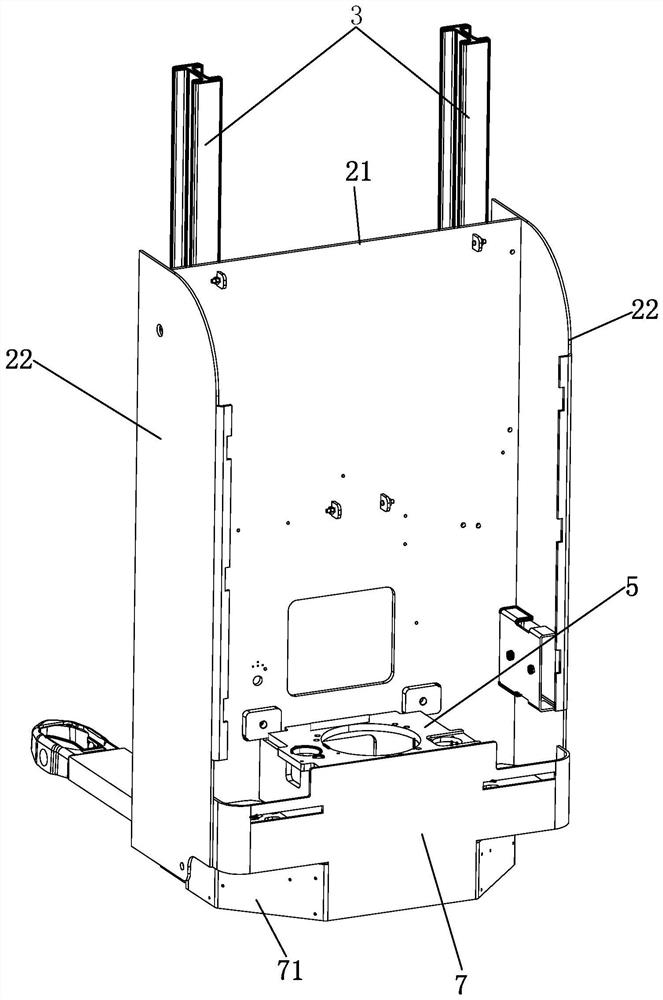

[0029] See Figure 1-Figure 3 As shown, a compact AGV vehicle frame of the present invention includes a vehicle frame chassis 1, a vehicle frame body 2, two door frame steels 3, a battery installation part, and a drive system installation part; the vehicle frame frame body 2 is arranged on the vehicle frame On the chassis 1; the frame body 2 includes a vertical plate 21 and two side plates 22, and the two side plates 22 are respectively fixed on the left and right ends of the vertical plate 21, and form an I-shape with it; On the front side of the vertical board 21 and between the two side boards 22; the battery installation part is fixed on the rear side of the vertical board 21 and between the two side boards 22; the drive system installation part is fixed on the rear side of the vertical board 21 and is located Between the side panels 22.

[0030] In this embodiment, the AGV vehicle frame of the present invention also includes a rear tailgate 7 that can be installed with a...

Embodiment 2

[0040] See Figure 6-Figure 8 As shown, a compact AGV frame of the present invention differs from the first embodiment above in that: the frame chassis 1 includes two left and right legs 11, and the bottom ends of the risers 21 are respectively connected to the two legs. 11 fixed connection; the installation part of the driving system 20 includes a driving fixing plate 5, the driving fixing plate 5 is located between the two portal frame steels 3, and the left and right ends of the driving fixing plate 5 pass through a fixing bracket 8 and The rear ends of the two legs 11 are connected, and the bottom of the vertical plate 21 is provided with an accommodation gap 213 for avoiding the drive fixing plate 5 and the drive system 20 installed thereon. The drive fixing plate 5 is suitable for installing a horizontal drive system 20 (the power part and drive wheels of the drive system 20 are distributed left and right).

[0041] In this embodiment, the fixed bracket 8 includes a fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com