Method for preparing triisobutylene by oligomerization of isobutylene

A technology of triisobutene and isobutene, which is applied in the field of isobutene oligomerization to prepare triisobutene, can solve the problems of catalyst deactivation when encountering polar substances, low triisobutene selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

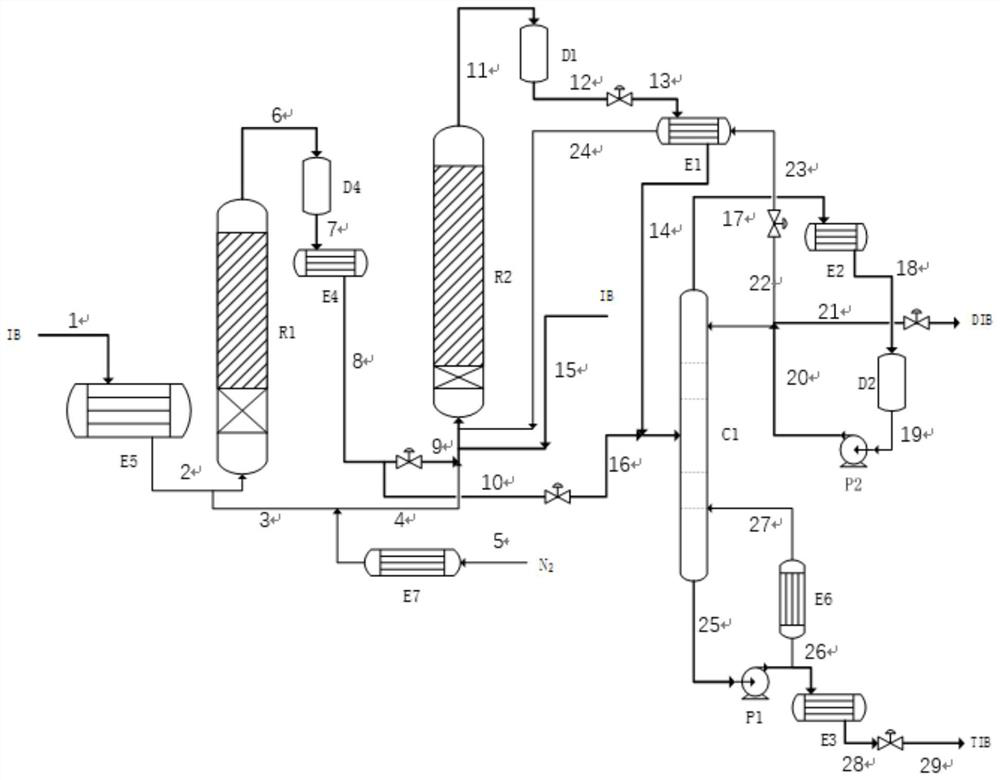

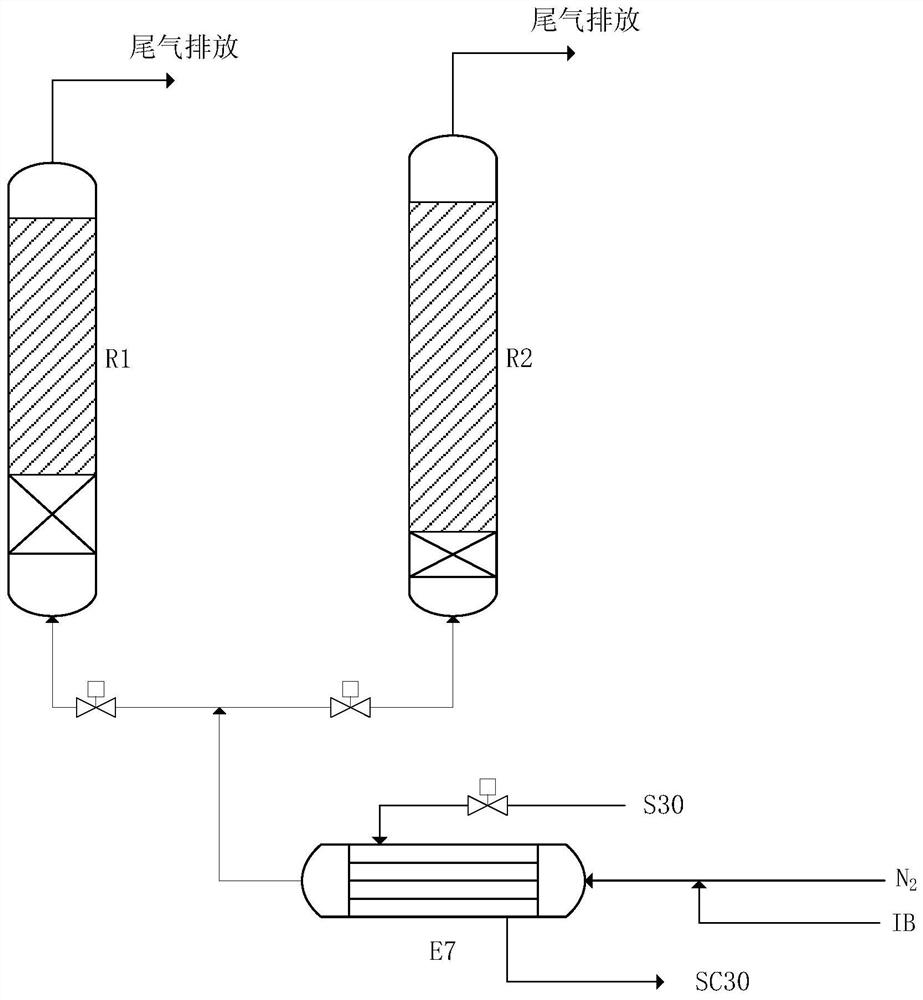

[0066] combined with figure 1 , the lower part of the first reactor R1 and the second reactor R2 are filled with adsorbent spherical alumina, and the upper part is filled with catalyst macroporous cationic sulfonic acid resin (purchased by the manufacturer: Dow). The catalyst filling height in the first reactor is the adsorbent 4 times of the packing height, and the catalyst packing height in the second reactor is 8 times of the adsorbent packing height. The catalyst loading volume of the second reactor R2 is 10 times that of the first reactor R1. Isobutene from outside the device at a temperature of 15°C, a pressure of 0.4MPa, and a flow rate of 80kg / h is heated to 60°C by the feed heater E5 of the raw material IB and enters the reactor from the bottom of the first reactor R1 for oligomerization. Among them, the first reactor feed volume space velocity is 4h -1 , the reaction pressure is controlled at 2.0 MPa, and at this time, the first reactor R1 is a liquid phase reactio...

Embodiment 2

[0071] combined with figure 1 The first reactor R1 and the second reactor R2 are loaded with adsorbent and catalyst as in Example 1, and the isobutylene from outside the device with a temperature of 15°C, a pressure of 0.4MPa, and a flow rate of 80kg / h is heated by the feed heater E5 of the raw material IB It enters the reactor from the bottom of the first reactor R1 to 60°C for oligomerization. Among them, the first reactor feed volume space velocity is 4h -1 , the reaction pressure is controlled at 2.0 MPa, and at this time, the first reactor R1 is a liquid phase reaction. After the material at the outlet of the first reactor R1 is stored in the buffer tank D4 at the outlet of the first reactor, about 40kg of it is cooled to 30°C by the outlet cooler E4 of the first reactor and enters the second reactor R2; the other about 40kg enters the Separation column C1.

[0072] About 30.4kg of the top material of separation tower C1 (about 28.5kg of by-product diisobutylene) is re...

Embodiment 3

[0076] combined with figure 1 The first reactor R1 and the second reactor R2 are loaded with the same adsorbent and catalyst as in Example 1, and the isobutylene from outside the device at a temperature of 15° C., a pressure of 0.4 MPa, and a flow rate of 80 kg / h is fed to the heater E5 through raw material IB. Heating to 60°C enters the reactor from the bottom of the first reactor R1 for oligomerization. Among them, the first reactor feed volume space velocity is 4h -1 , the reaction pressure is controlled at 2.0 MPa, and at this time, the first reactor R1 is a liquid phase reaction. After the material at the outlet of the first reactor R1 is stored in the buffer tank D4 at the outlet of the first reactor, about 32kg is cooled to 30°C by the outlet cooler E4 of the first reactor and enters the second reactor R2; the other about 48kg enters the Separation column C1.

[0077] About 35.4kg of the top material of the separation tower C1 (about 33.5kg of by-product diisobutene)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com