Synthesis of an ionic liquid-based fluorescent hydrogel sensor and its application in the detection of p-nitroaniline

A hydrogel and sensor technology, applied in the application of detecting p-nitroaniline, in the field of synthesis of fluorescent hydrogel sensors, can solve problems such as sensitivity limitation, and achieve the effects of high sensitivity, simple synthesis method and short detection time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 300 mg of hydroxyethyl methacrylate, 3.5 mg of N,N'-methylenebisacrylamide, 4 mg of azobisisobutyronitrile, and 10 mg of 3-(anthracene-9-ylmethyl)-1-ethylene The base-1H-imidazole-3-onium chloride was added to 10 mL of dimethyl sulfoxide, sonicated for 10 min, added to the flask, and then added blank paper; evacuated and filled with argon, and carried out three cycles of degassing, argon purging, The flask was closed and placed in an oil bath at a temperature of 80 °C for 15 h; washed with ethanol, dimethyl sulfoxide and deionized water in turn, and dried in vacuum to synthesize a fluorescent hydrogel sensor.

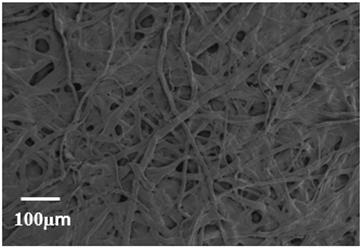

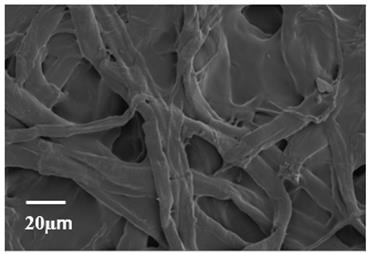

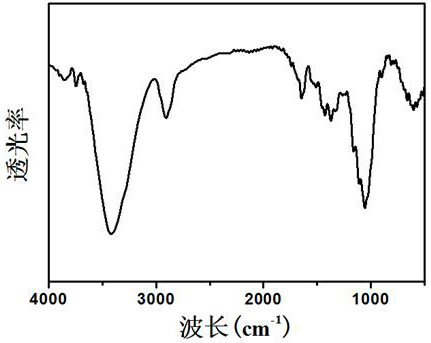

[0027] 1. Microscopic morphology of the fluorescent hydrogel sensor.

[0028] Microscopic morphology: The microscopic morphology of the fluorescent hydrogel sensor synthesized in Example 1 was observed by scanning electron microscope. figure 1 and figure 2 As shown, it can be seen that the fibrous network structure of the filter paper is wrapped with a h...

Embodiment 2

[0037]Weigh 600 mg of hydroxyethyl methacrylate, 7 mg of N,N'-methylenebisacrylamide, 8 mg of azobisisobutyronitrile, and 20 mg of 3-(anthracene-9-ylmethyl)-1-vinyl -1H-imidazol-3-onium chloride was added to 20 mL of dimethyl sulfoxide, sonicated for 10 min, added to the flask, and then added to the textile; vacuumed and filled with argon, degassed for three cycles, purged with argon, and sealed The flask was placed in an oil bath at 60°C for 24 hours; washed with ethanol, dimethyl sulfoxide, and deionized water in turn, and dried in vacuum to synthesize a fluorescent hydrogel sensor.

Embodiment 3

[0039] Weigh 450 mg of hydroxyethyl methacrylate, 5.25 mg of N,N'-methylenebisacrylamide, 6 mg of azobisisobutyronitrile, and 15 mg of 3-(anthracene-9-ylmethyl)-1-ethylene The base-1H-imidazole-3-onium chloride was added to 7.5 mL of dimethyl sulfoxide, sonicated for 10 min, added to the flask, and then added to the textile; vacuumed and filled with argon, degassed for three cycles, and purged with argon. , closed the flask, and placed it in an oil bath at 100 °C for 8 h; washed with ethanol, dimethyl sulfoxide, and deionized water in turn, and vacuum-dried to synthesize a fluorescent hydrogel sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com