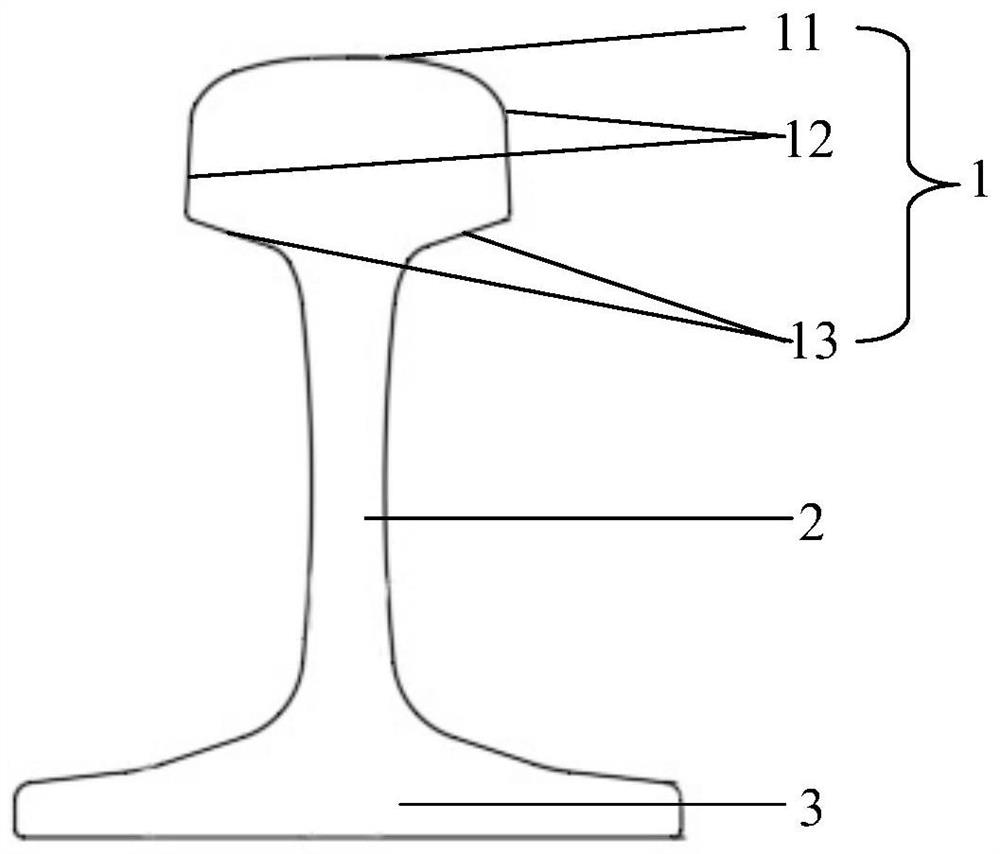

High-strength and high-toughness steel rail and preparation method thereof

A high-strength toughness, rail technology, applied in the field of rail manufacturing, can solve the problem of poor toughness and plasticity of heavy-duty rails, achieve excellent strength and toughness, and improve the effect of toughness and plasticity of rails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

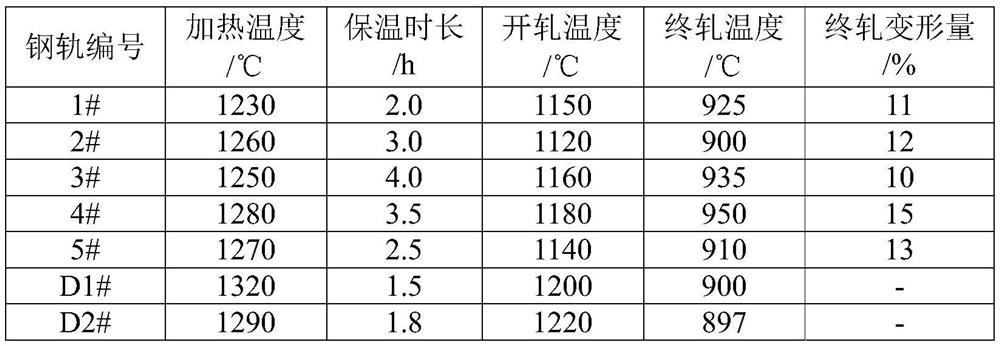

[0032] A first aspect of the present invention provides a method for preparing a high-strength toughness steel rail, the method comprising the following steps:

[0033] (1) Low-S molten iron is put into the furnace, and the molten steel is softly blown with argon under the protection of high-alkalinity refining slag to homogenize the alloy composition. The argon blowing time is 5 minutes to 10 minutes.

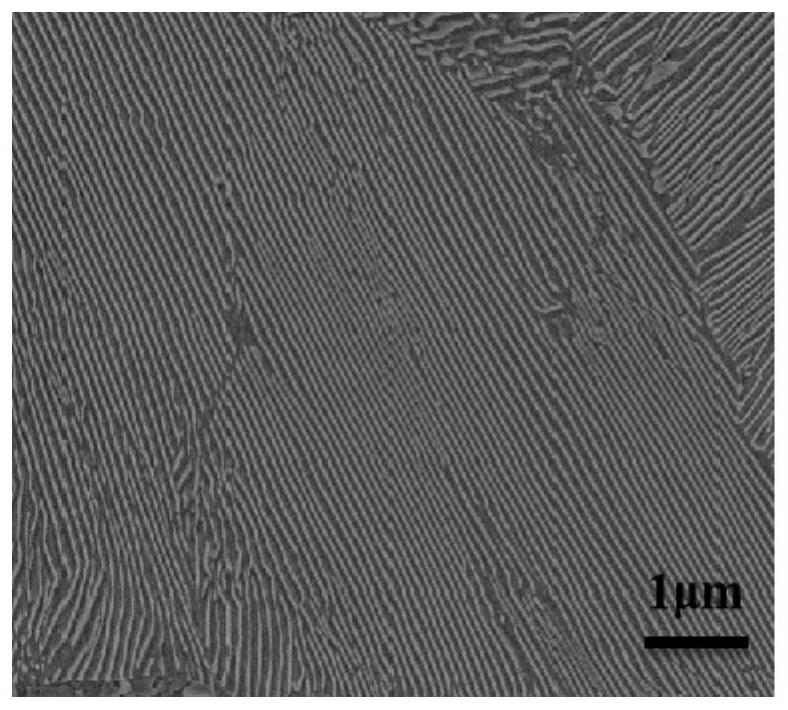

[0034](2) The molten steel after argon blowing in step (1) is refined by electric heating in the LF furnace and the main alloy components are precisely regulated. After the LF refining is completed, the RH vacuum cycle degassing treatment is performed, and the obtained molten steel is passed through the continuous casting process. A rail billet is formed. The composition of the rail billet needs to meet the following requirements in terms of mass percentage: C: 0.65-0.85%, Si: 0.3-0.8%, Mn: 0.5-1.0%; Cr: 0.5-1.2%; V: 0.05-0.13%, S≤ 0.008%, P≤0.025%, the balance is Fe and unav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com