Ta-W-Hf-Re-C alloy and preparation method of Ta-W-Hf-Re-C alloy bar

An alloy and rod technology, applied in the field of refractory metal alloy preparation, can solve the problems of easy failure, sudden drop in creep resistance of tantalum-tungsten alloy, poor oxidation resistance, etc., to avoid a large amount of volatilization, ensure performance, and improve resistance Corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

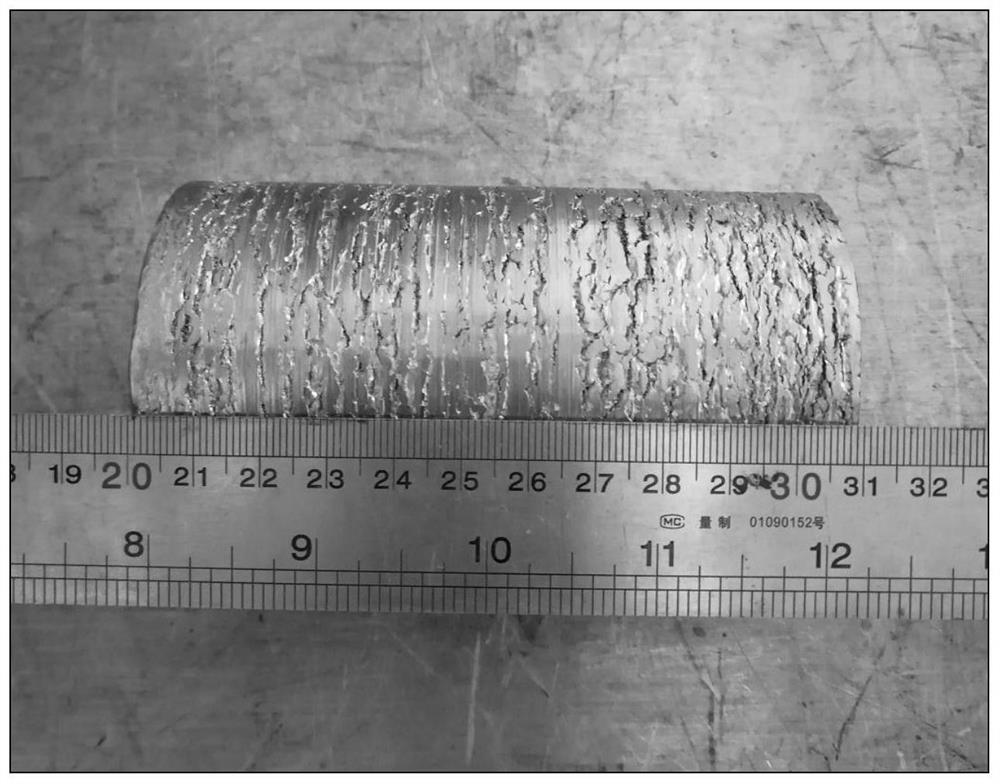

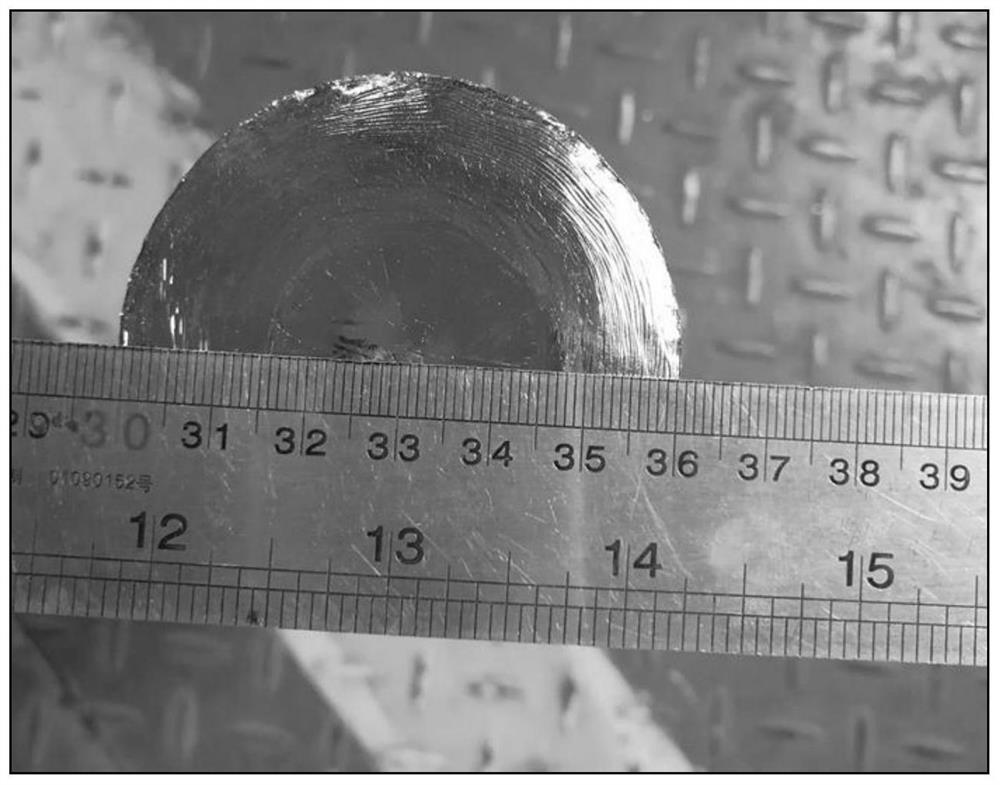

Image

Examples

Embodiment 1

[0033] The Ta-W-Hf-Re-C alloy of this embodiment is composed of the following elements by mass percentage: a Ta-W-Hf-Re-C alloy, which is characterized in that it is composed of the following elements by mass percentage : W 6.6%, Hf 5%, Re 0.9%, C0.35%, the balance is Ta and inevitable impurities.

[0034] The preparation method of the bar of the Ta-W-Hf-Re-C alloy of the present embodiment comprises the following steps:

[0035] Step 1. According to the design content of the target product Ta-W-Hf-Re-C alloy bar, the tantalum powder, tungsten powder, hafnium powder, rhenium powder and carbon powder are mixed with a V-type mixer for 24 hours, and after mixing After the obtained mixed powder is completely cooled, it is molded with a 600T press to obtain a billet with a size (width × height × length) of 16 mm × 16 mm × 400 mm; the tantalum powder, tungsten powder, hafnium powder, rhenium powder and carbon powder are The particle size is no more than 60 mesh, and the mass purity...

Embodiment 2

[0042] The Ta-W-Hf-Re-C alloy of this embodiment is composed of the following elements by mass percentage: a Ta-W-Hf-Re-C alloy, which is characterized in that it is composed of the following elements by mass percentage : W 7.3%, Hf 3.5%, Re 0.86%, C 1.56%, the balance is Ta and inevitable impurities.

[0043] The preparation method of the bar of the Ta-W-Hf-Re-C alloy of the present embodiment comprises the following steps:

[0044] Step 1. According to the design content of the target product Ta-W-Hf-Re-C alloy bar, the tantalum powder, tungsten powder, hafnium powder, rhenium powder and carbon powder are mixed with a V-type mixer for 24 hours, and after mixing After the obtained mixed powder is completely cooled, it is molded with a 600T press to obtain a billet with a size (width × height × length) of 16 mm × 16 mm × 400 mm; the tantalum powder, tungsten powder, hafnium powder, rhenium powder and carbon powder are The particle size is no more than 60 mesh, and the mass pu...

Embodiment 3

[0051] The Ta-W-Hf-Re-C alloy of this embodiment is composed of the following elements by mass percentage: a Ta-W-Hf-Re-C alloy, which is characterized in that it is composed of the following elements by mass percentage : W 7.3%, Hf 3%, Re 0.9%, C2%, the balance is Ta and inevitable impurities.

[0052] The preparation method of the bar of the Ta-W-Hf-Re-C alloy of the present embodiment comprises the following steps:

[0053] Step 1. According to the design content of the target product Ta-W-Hf-Re-C alloy bar, the tantalum powder, tungsten powder, hafnium powder, rhenium powder and carbon powder are mixed with a V-type mixer for 24 hours, and after mixing After the obtained mixed powder is completely cooled, it is molded with a 600T press to obtain a billet with a size (width × height × length) of 16 mm × 16 mm × 400 mm; the tantalum powder, tungsten powder, hafnium powder, rhenium powder and carbon powder are The particle size is no more than 60 mesh, and the mass purity is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Room temperature tensile strength | aaaaa | aaaaa |

| Room temperature yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com