High-precision anti-seismic pressure gauge for ship

A technology for pressure gauges and ships, applied in the field of instruments, can solve the problems of affecting the pressure measurement accuracy and poor seismic performance of pressure gauges, and achieve the effect of improving measurement accuracy, improving seismic performance, and reducing the possibility of loose connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is attached Figure 1-4 The application is described in further detail.

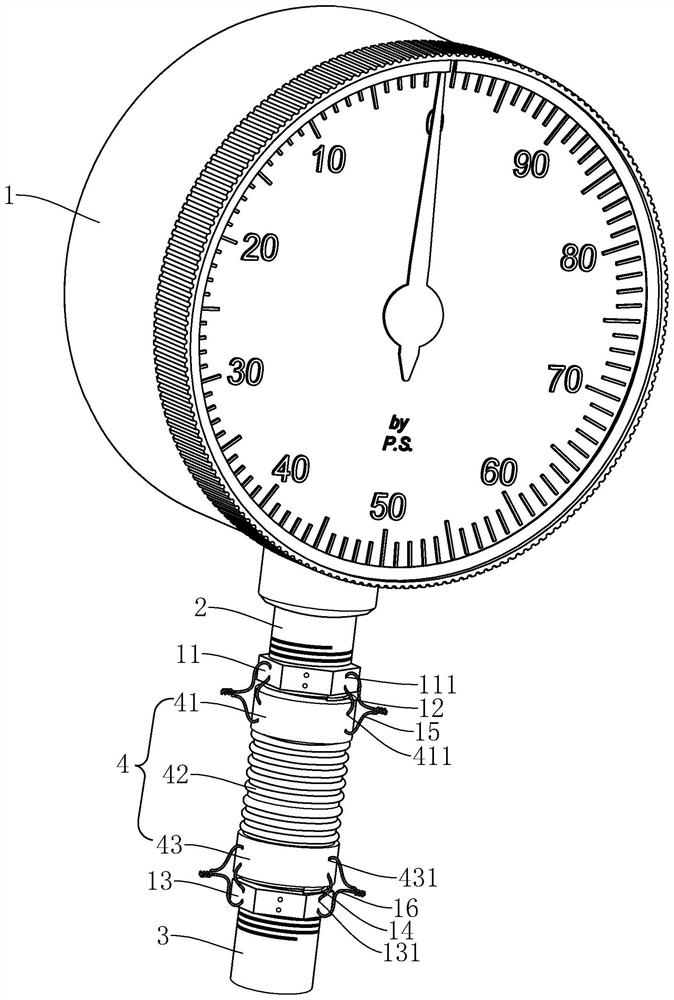

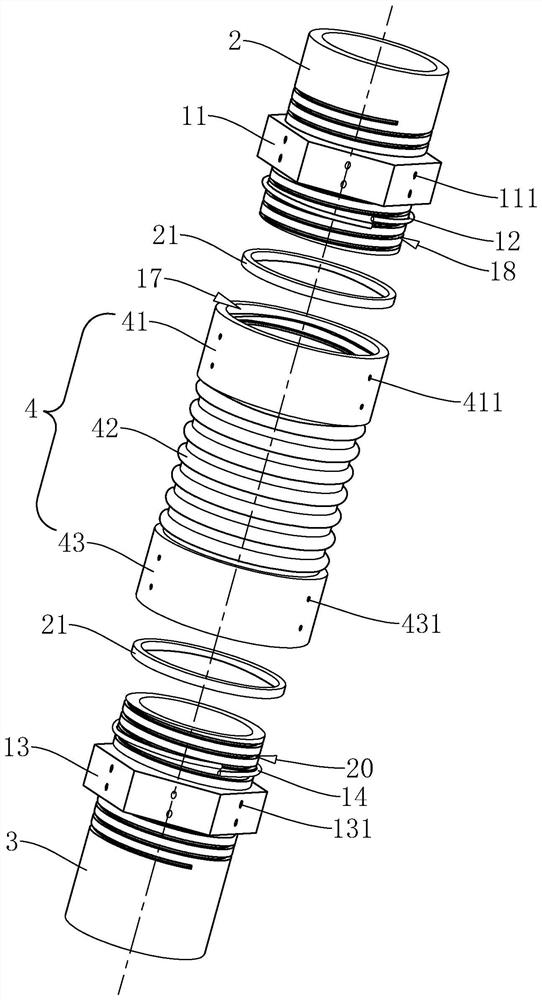

[0036] The embodiment of the present application discloses a high-precision earthquake-resistant ship pressure gauge. refer to figure 1 The high-precision anti-seismic ship pressure gauge includes a pressure gauge body 1, an upper joint 2 and a lower joint 3, the upper joint 2 and the pressure gauge body 1 are fixedly connected, and the upper joint 2 and the lower joint 3 are connected by an anti-seismic tube 4, The lower joint 3 is connected to the ship pipeline, and the pressure gauge body 1 is connected with the ship pipeline through the upper joint 2, the anti-seismic pipe 4 and the lower joint 3, so that the pressure gauge body 1 can detect the medium pressure in the ship pipeline.

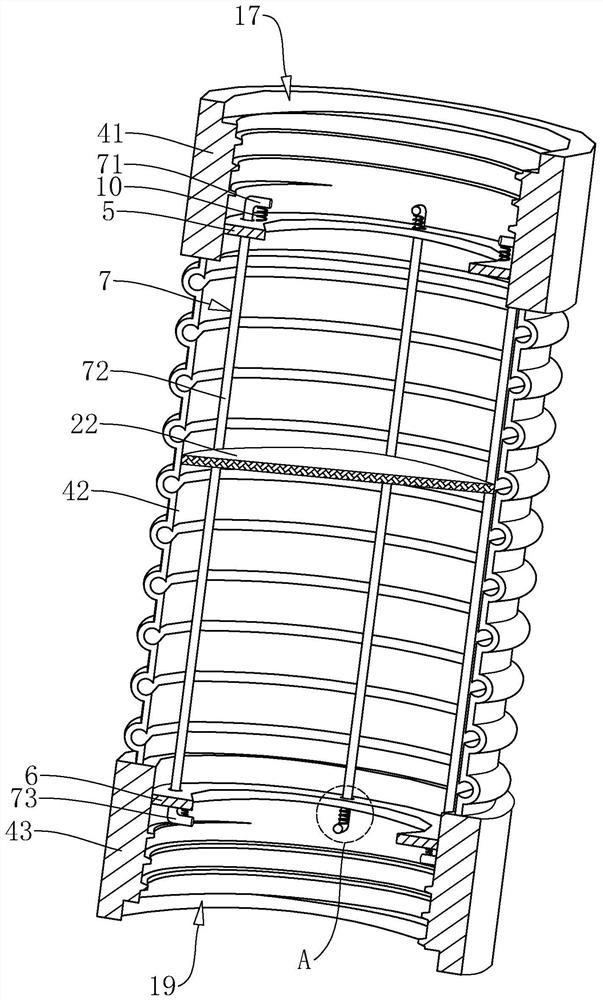

[0037] refer to figure 1The anti-seismic pipe 4 is composed of an upper connecting pipe 41 , a lower connecting pipe 43 and a corrugated section 42 , and the corrugated section 42 is integrally f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com