Permanent magnet bias inductor tuning device and method with parallel magnetic circuits

A permanent magnet bias and tuning device technology, applied in the direction of transformer/inductor magnetic core, continuously variable inductor/transformer, preventing/reducing unnecessary electric/magnetic influence, etc., can solve the problem that DC control cannot be realized Efficient use of coils, inability to adjust the magnetic flux density of the middle core, and insignificant changes in magnetic permeability, etc., to achieve the effects of weakening the core operating point offset, expanding the inductance adjustment range, and optimizing the adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0030] This invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

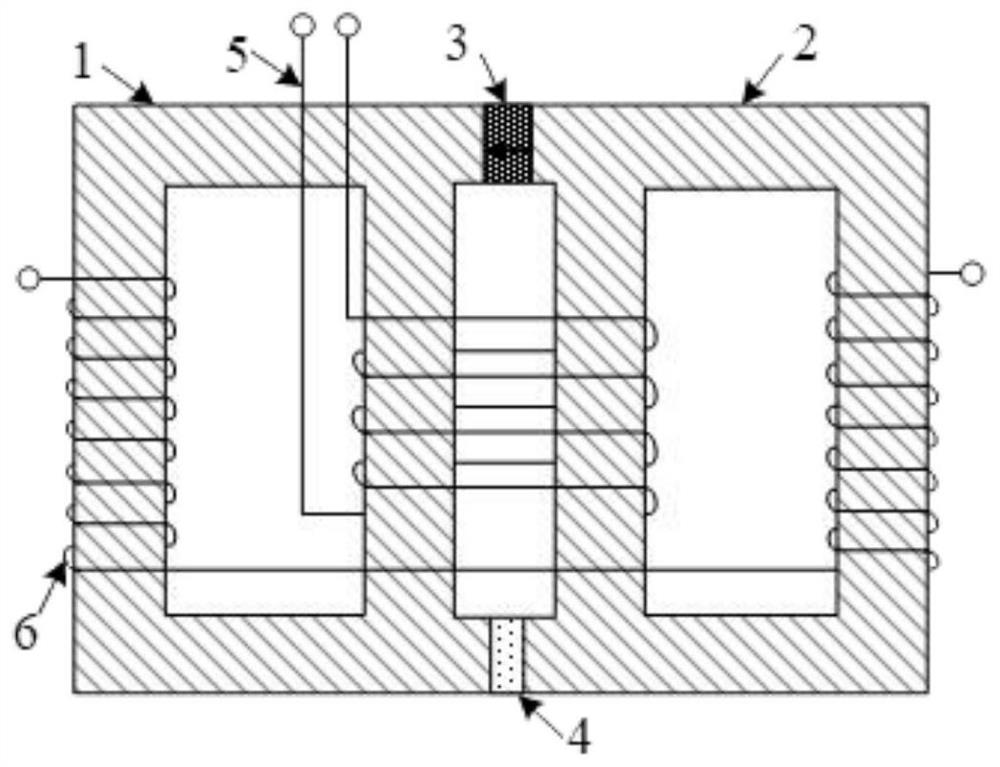

[0031] Such as figure 1 as shown, figure 1 It is a schematic diagram of the overall structure of a permanent magnet bias inductance tuning device with a parallel magnetic circuit proposed by the present invention. The device includes a left magnetic core 1, a right magnetic core 2, a permanent magnet 3, an air gap 4, an inductance tuning coil 5, a DC Control coil 6;

[0032] Among them, the left magnetic core 1 and the right magnetic core 2 are placed side by side, the permanent magnet 3 and the air gap 4 are arranged between the left magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com