Photonic crystal surface emitting type laser structure

A photonic crystal and laser structure technology, which is applied in the direction of semiconductor lasers, lasers, phonon exciters, etc., can solve the problem of excessive divergence angle and threshold current, and achieve the effect of reducing divergence angle and threshold current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the description of the present disclosure more detailed and complete, reference may be made to the drawings and various implementations described below. Elements in the drawings are not drawn to scale and are provided merely to illustrate the present disclosure. Numerous practical details are described below in order to provide a thorough understanding of the present disclosure, however, those of ordinary skill in the relevant art will understand that the present disclosure can be practiced without one or more of the practical details, and thus, these details are not apply to define this disclosure.

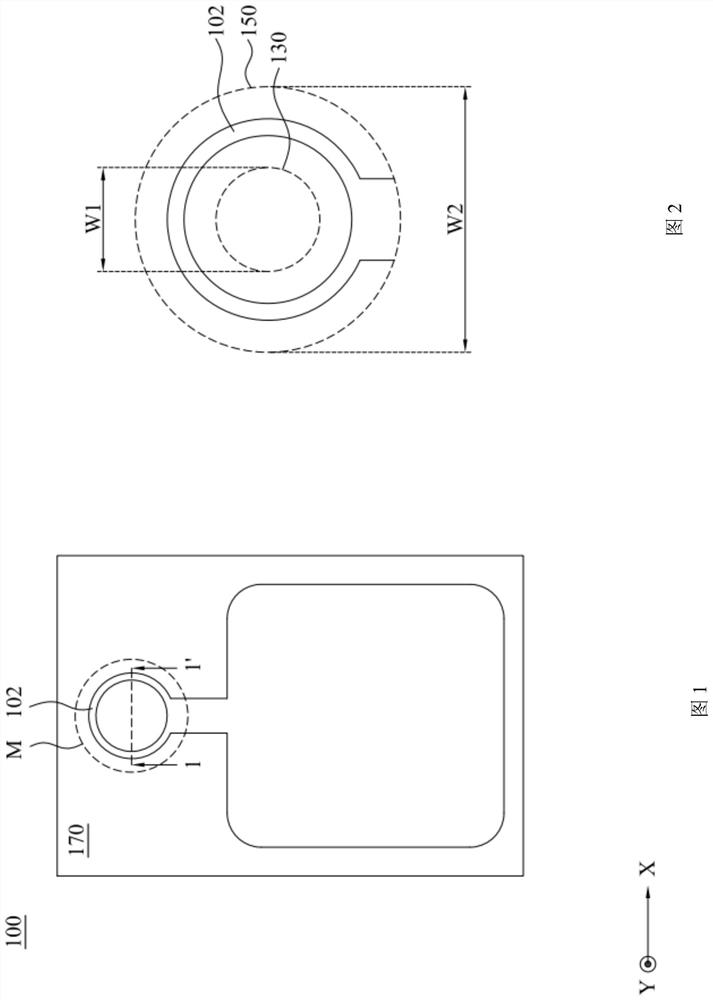

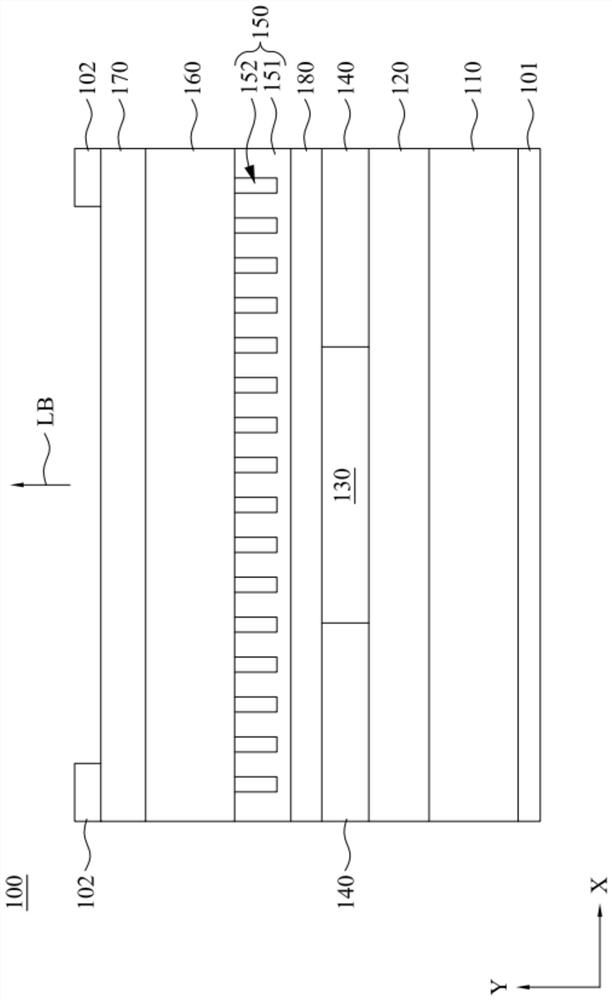

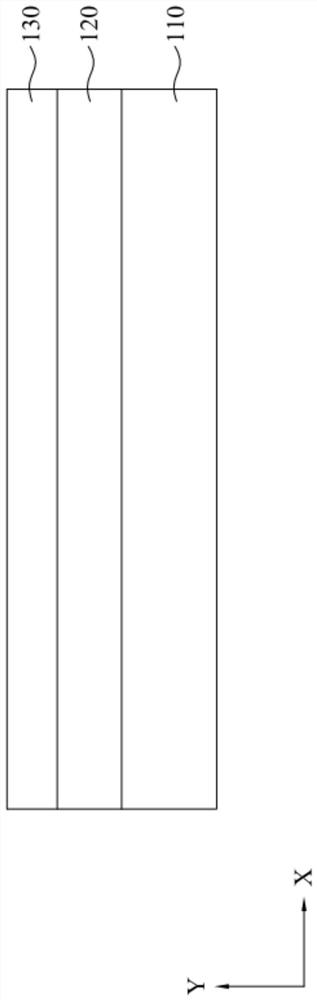

[0043] Please refer to Figure 1 to Figure 3 . figure 1 To illustrate a top view of a photonic crystal surface-emitting laser structure 100 according to an embodiment of the present disclosure, figure 2 for illustration figure 1 An enlarged perspective view of the shown photonic crystal surface-emitting laser structure 100 in the region M, image 3 b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com