Split type twisted cable twist stopping device and assembling method

A split and twisted cable technology, which is applied in the direction of cable installation, cable layout between relative moving parts, cable laying equipment, etc., can solve problems affecting cable life, long installation time, alternating load force, etc., and achieve reduction The effect of relative friction damage, improving service life and avoiding lateral impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention is made further embodiment. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

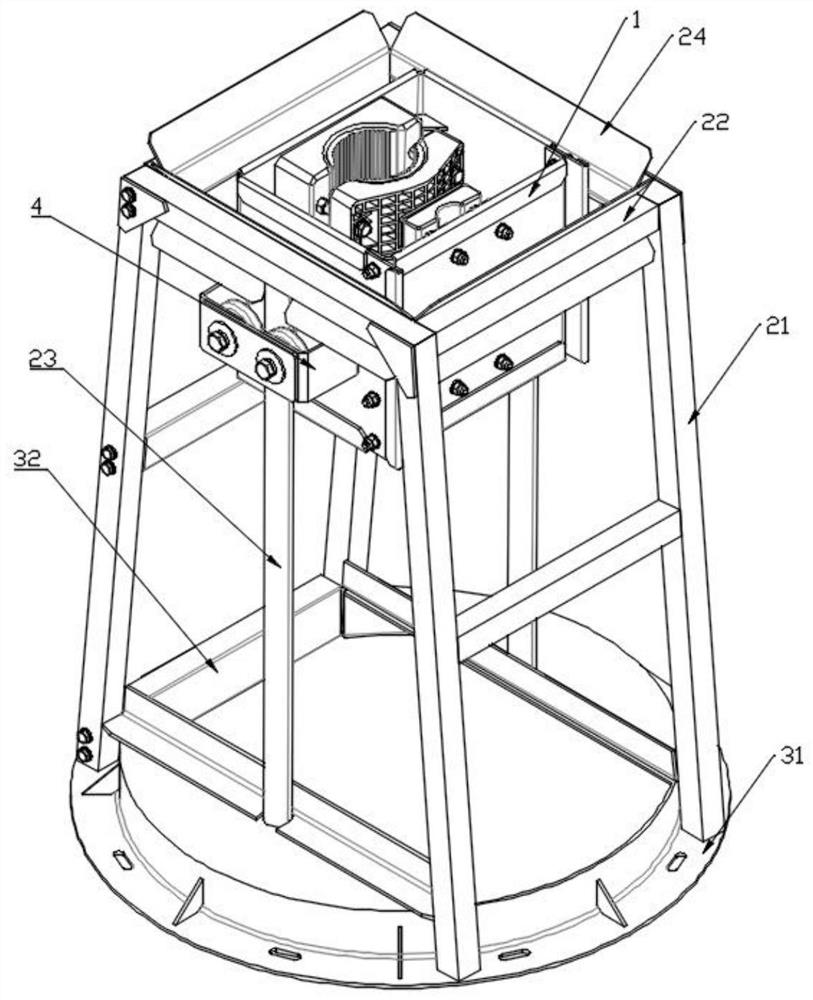

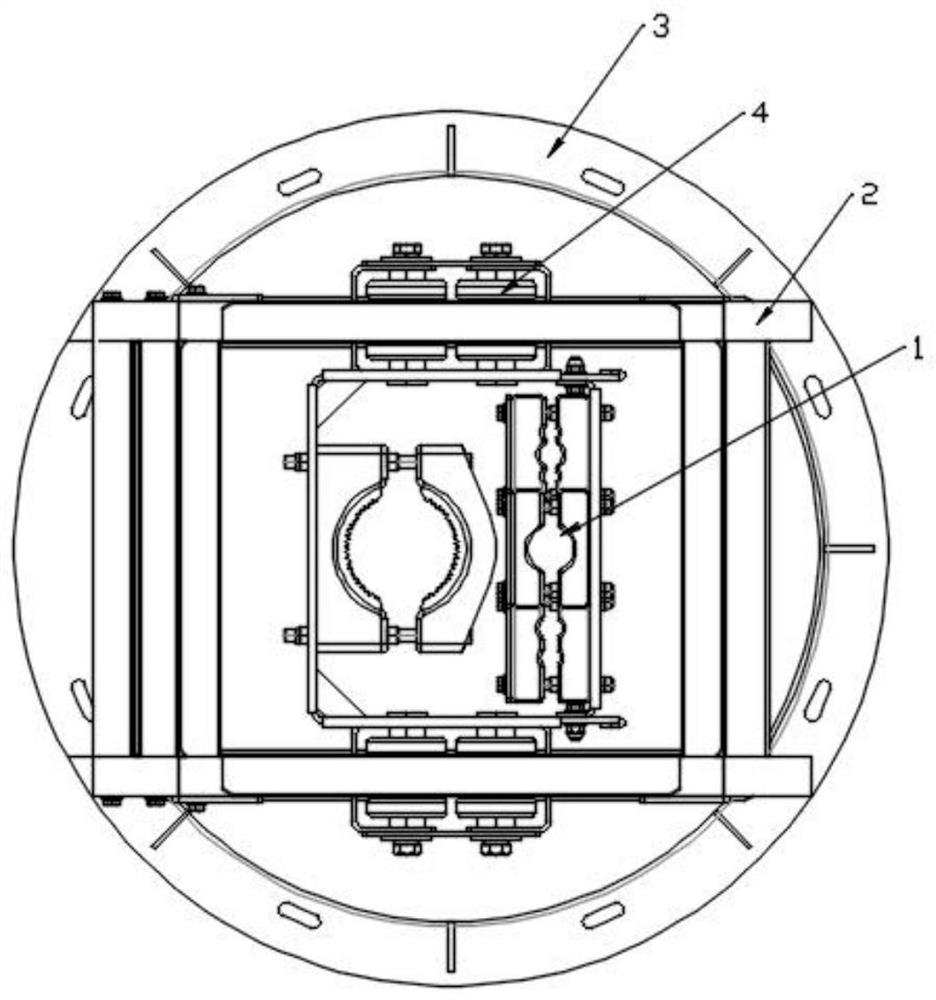

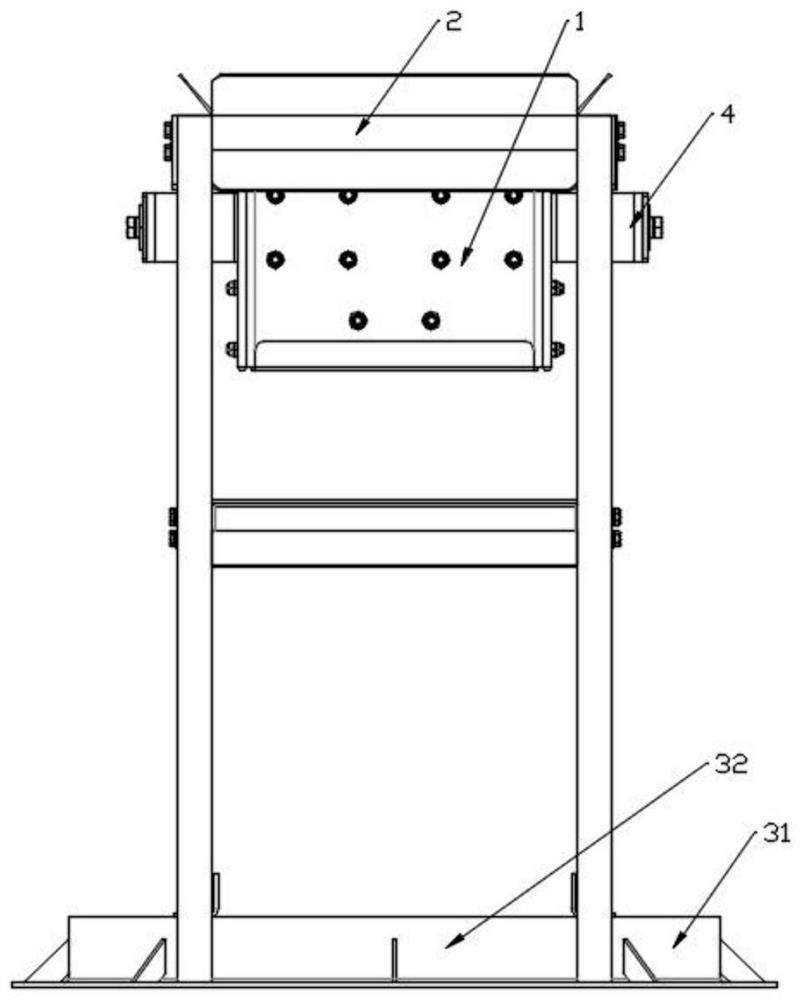

[0033] As shown in the figure, this embodiment provides a split-type twisted cable anti-twist device, including a partition assembly 1, a guide pulley group 4 and a fixed bracket 2. The partition assembly 1 is used to limit the rotation of the twisted cable and can move along with the twisted cable. The twisted cable moves in the axial direction, the bottom of the fixed bracket 2 is fixedly connected to the saddle platform at the bottom of the tower through the split flange 3, a cable suspension section of a certain length is arranged under the saddle platform, and the partition assembly 1 is arranged on the left and right sides. The guide pulley group 4 slides along th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap