Cable robot

A robot and cable technology, which is applied in the direction of cable cranes, manipulators, cranes, etc., can solve the problems of the influence of the positioning accuracy of the working head, the complexity of the cable robot, and the difficulty of transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

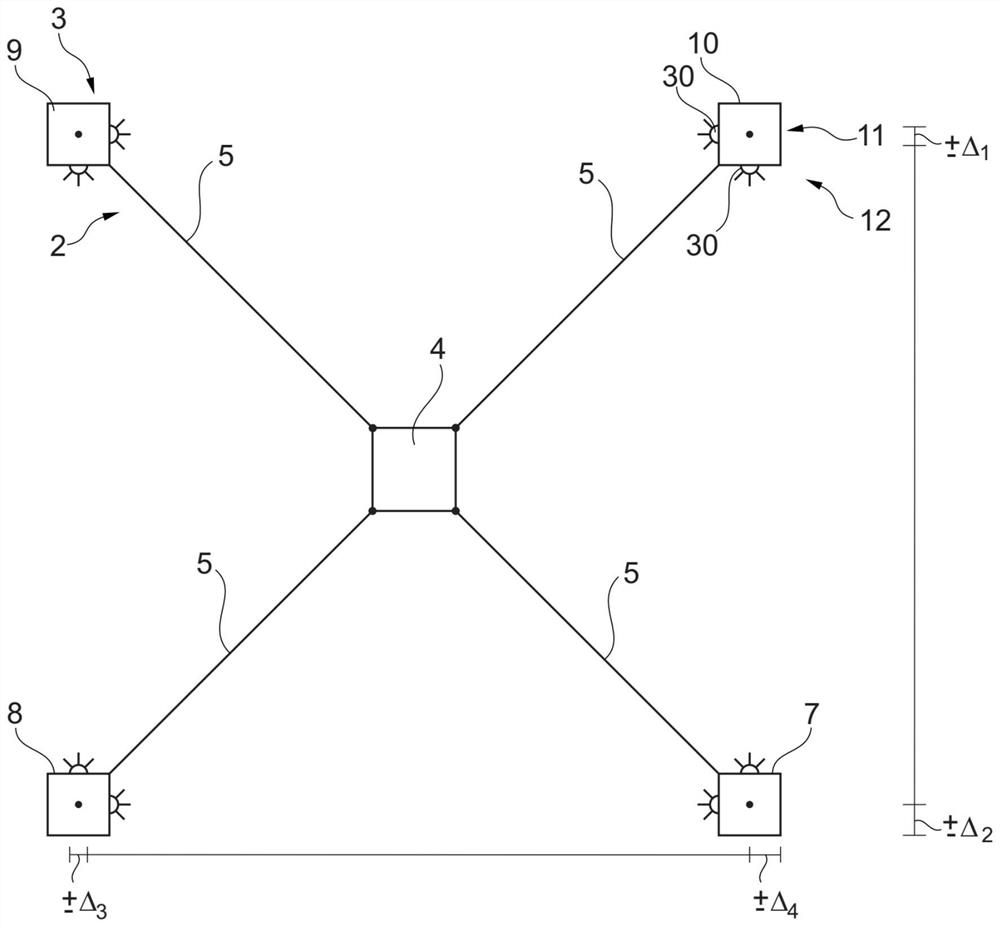

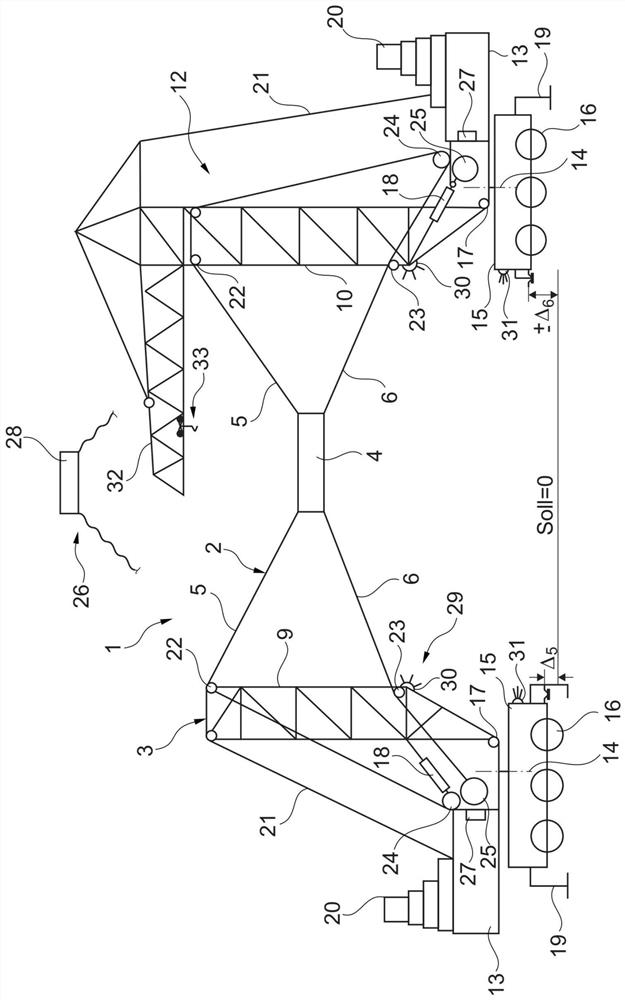

[0037] As shown, the cable robot 1 comprises a cable system 2 tensioned by a support structure 3 and carrying a working head 4 .

[0038] The working head 4 can be configured differently and / or equipped with different working tools, for example in the form of material delivery heads such as concrete sprinklers or other manufacturing tools and / or workpiece grippers such as clamshell grabs or other The form of the processing tool.

[0039] Here, if figure 1 As shown, the cable system 2 may comprise cables extending in four cardinal directions or in four different vertical planes, wherein advantageously for each cardinal direction or in each vertical plane there may be provided two cables 5, 6. These two cables can run from hinge points arranged at different heights, in particular can guide the working head 4 once obliquely upward and once obliquely downward (see figure 2 ).

[0040] In particular, the support structure may comprise four individual, respectively vertical supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com