Deep-cavity filter plate combined filter press

A combined, filter press technology, applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve problems such as failure to find damaged parts in time, increase enterprise costs, reduce filter press service life, etc. Standardize the operation process, improve the degree of automation, and increase the efficiency of the filter press

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

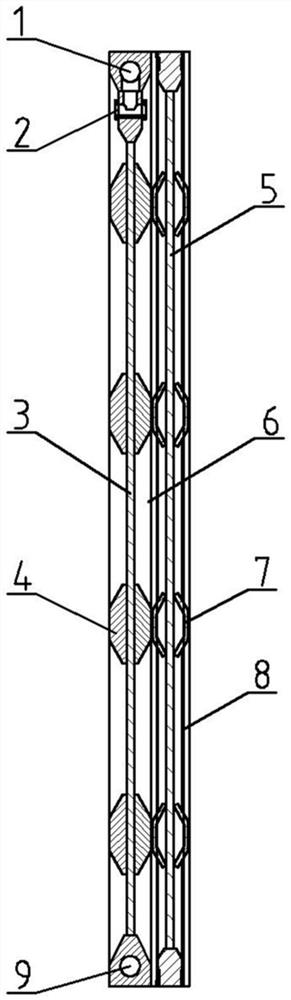

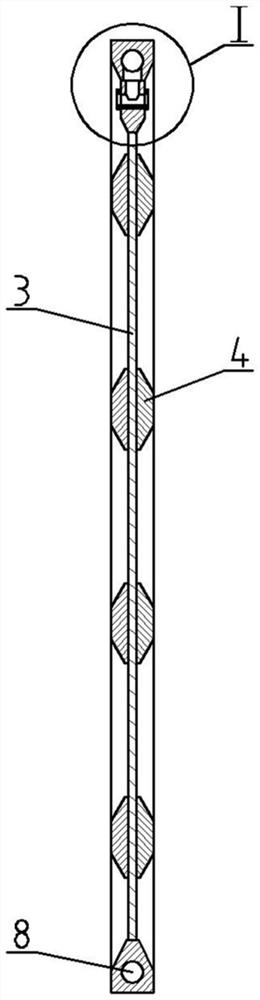

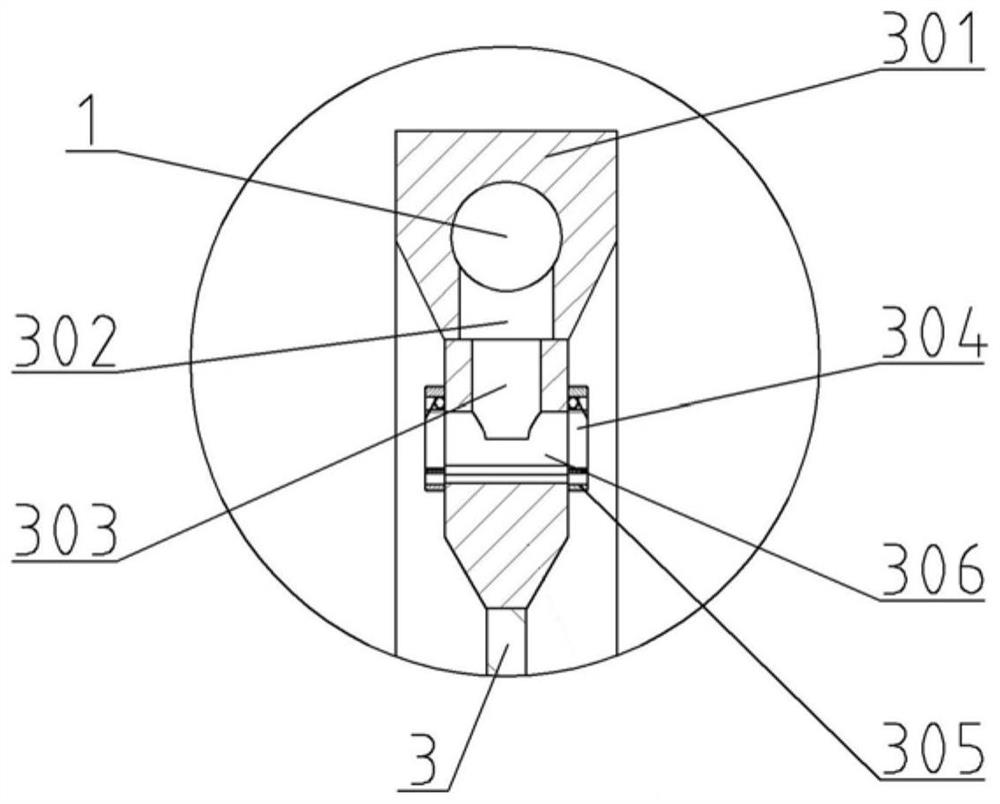

[0031] like Figure 1-6 As shown, the overall structural schematic diagram of the deep cavity filter plate combined filter press of the present invention is provided, and the shown deep cavity filter plate combined filter press includes a box type filter plate 3, a membrane filter Plate 5 and PLC automatic control system, and a sealed filter chamber 6 is formed between adjacent box filter plates 3 and diaphragm filter plates 5 . The upper and lower ends of the box-type filter plate 3 are respectively provided with a feed pipe 1 and an outlet pipe 9, the lower end of the feed pipe 1 is provided with a discharge port 2, the discharge port 2 communicates with the inner cavity of the filter chamber 6, and the discharge pipe 9 The upper end of the upper end is provided with a water inlet for filtered water infiltration, and the water inlet communicates with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com