Heat flux based laser cleaning quality online detection system and method

A laser cleaning and detection system technology, which is applied in the field of laser cleaning, can solve the problems of difficult micron-level defect detection, difficult to guarantee detection accuracy, and does not support online detection, etc., and achieves the effect of not being easy to interfere, simple in structure, and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Next, the structure, principle and specific implementation method of the present invention will be described in more detail with reference to the accompanying drawings.

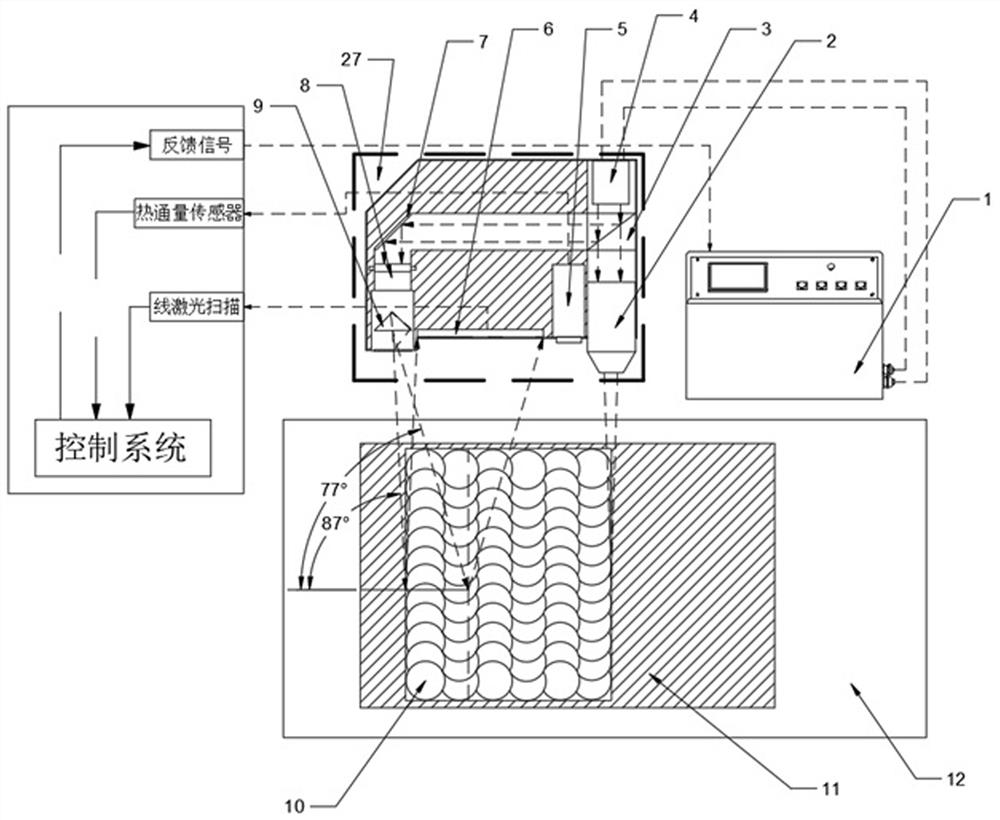

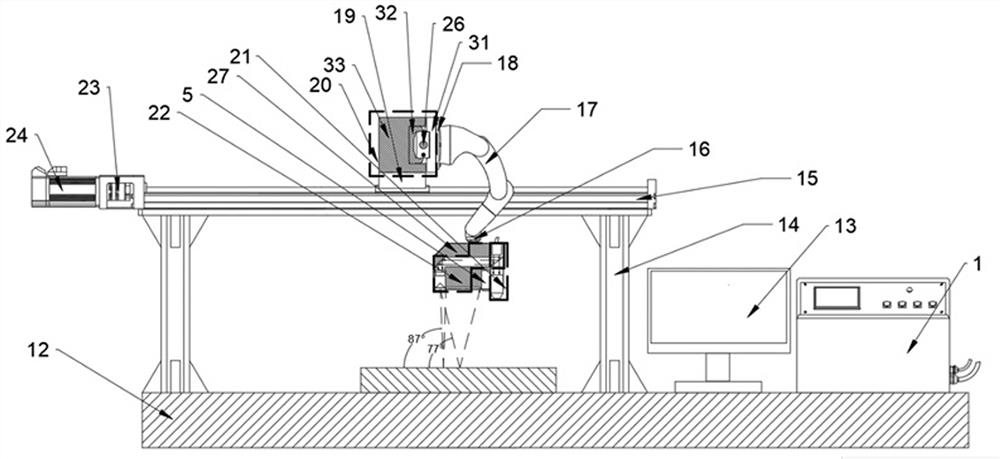

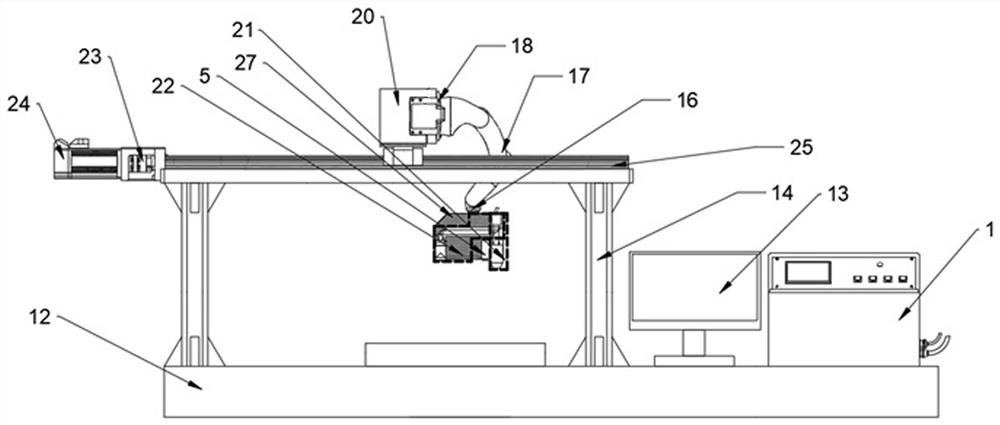

[0042] Such as Figure 1~6 As shown, a laser cleaning quality online detection system based on heat flux, the support structure of the system is connected with a laser cleaning detection device 27 through a sliding connection, and the laser cleaning detection device 27 is used to clean the workpiece and to detect the laser cleaning quality and stomatal defects. Such as Figure 6 As shown, the laser cleaning and detection device 27 is a box structure similar to a cuboid, and the laser cleaning and detection device 27 is internally provided with a light outlet 4, a beam splitting prism 3, a laser head 2, a reflector 7, a cylindrical lens 8, a vibrating mirror 9, a laser Clean the lower surface of the detection device 27 (such as Figure 5 and 6 The lower surface of the lower surface) is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com